-42-

Model G0886 (Mfd. Since 01/19)

SECTION 6: MAINTENANCE

For optimum performance from this machine, this

maintenance schedule must be strictly followed.

Ongoing

To maintain a low risk of injury and proper

machine operation, if you ever observe any of the

items below, shut down the machine immediately

and fix the problem before continuing operations:

• Loose mounting bolts.

• Damaged or dull saw blade.

• Worn or damaged wires.

• Any other unsafe condition.

Daily:

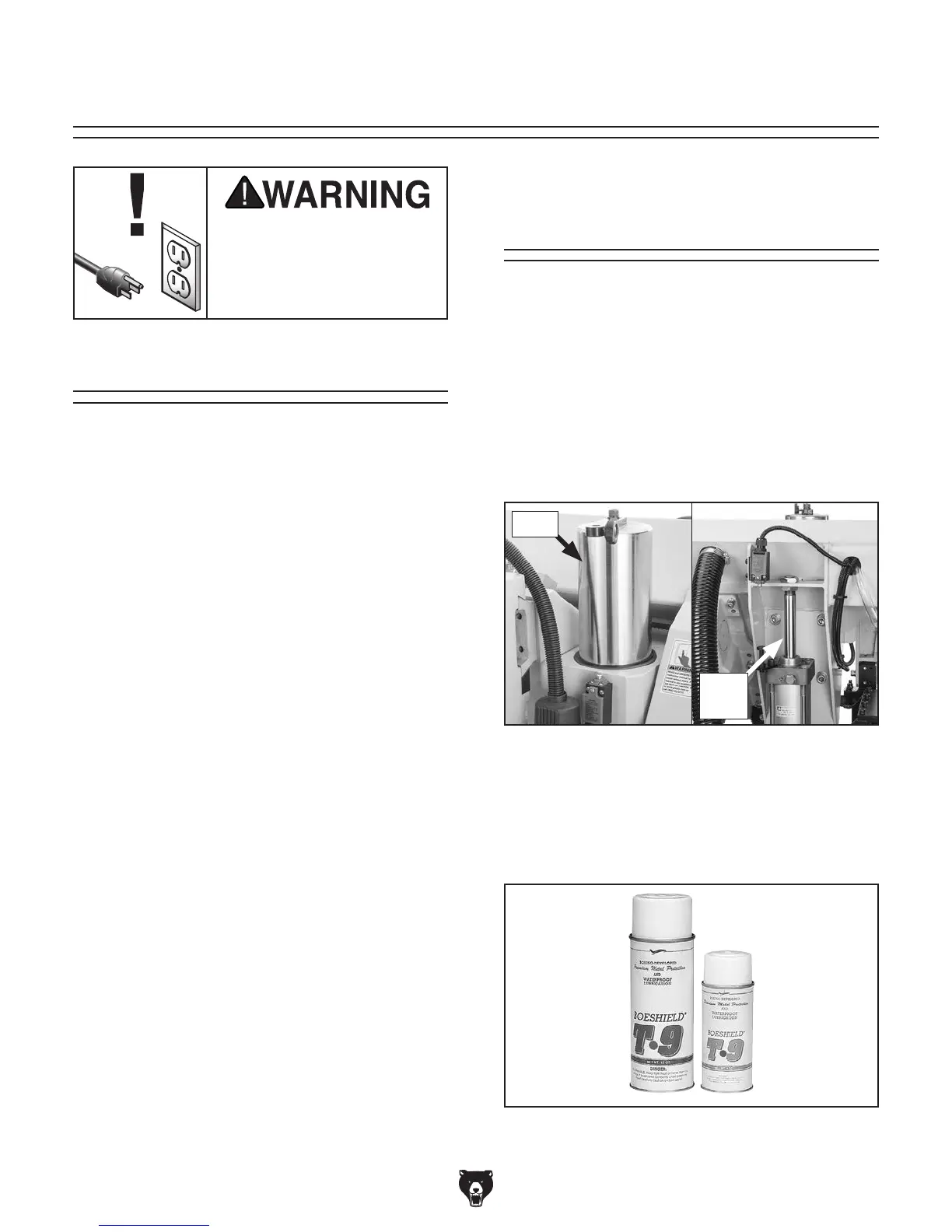

• Protect headstock pillar and ram strut (see

Figure 55).

• Lubricate blade and blade guides (Page 43).

• Clean/lubricate vise table (Page 44).

• Clean metal chips from upper and lower

wheel areas.

Monthly:

• Lubricate blade tension leadscrew (Page 43).

• Clean/lubricate vise leadscrew (Page 44).

• Lubricate headstock column (Page 44).

• Lubricate blade guide arm gib (Page 44).

• Remove blade and clean wheels.

• Check gearbox oil level (Page 45).

Bi-annually:

• Change gearbox oil (Page 45).

Schedule

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Cleaning &

Protecting

Use a brush and shop vacuum to remove chips

and other debris from the working surfaces.

Remove any rust build-up from unpainted cast

iron surfaces of your machine and treat with a

non-staining lubricant after cleaning.

Use a shop rag to apply a thin coat of quality

metal protectant to the headstock pillar and ram

strut (see Figure 55) to prevent corrosion.

G2870—T-9 Boeshield, 4 Oz.

G2871—T-9 Boeshield, 12 Oz.

This protective spray penetrates deep and holds

up the longest against corrosive environments.

Figure 56. T-9 Boeshield.

Figure 55. Location of headstock pillar and ram

strut.

Ram

Strut

Pillar

Headstock Pillar & Ram Strut

Boeshield

Loading...

Loading...