Although some figures might not exactly

represent your machine, this process is the

same on the G0945, G0946, and G0947.

The knives/indexable inserts are very sharp

and can easily cut your hands. ALWAYS

use caution when making adjustments near

these parts to reduce risk of personal injury.

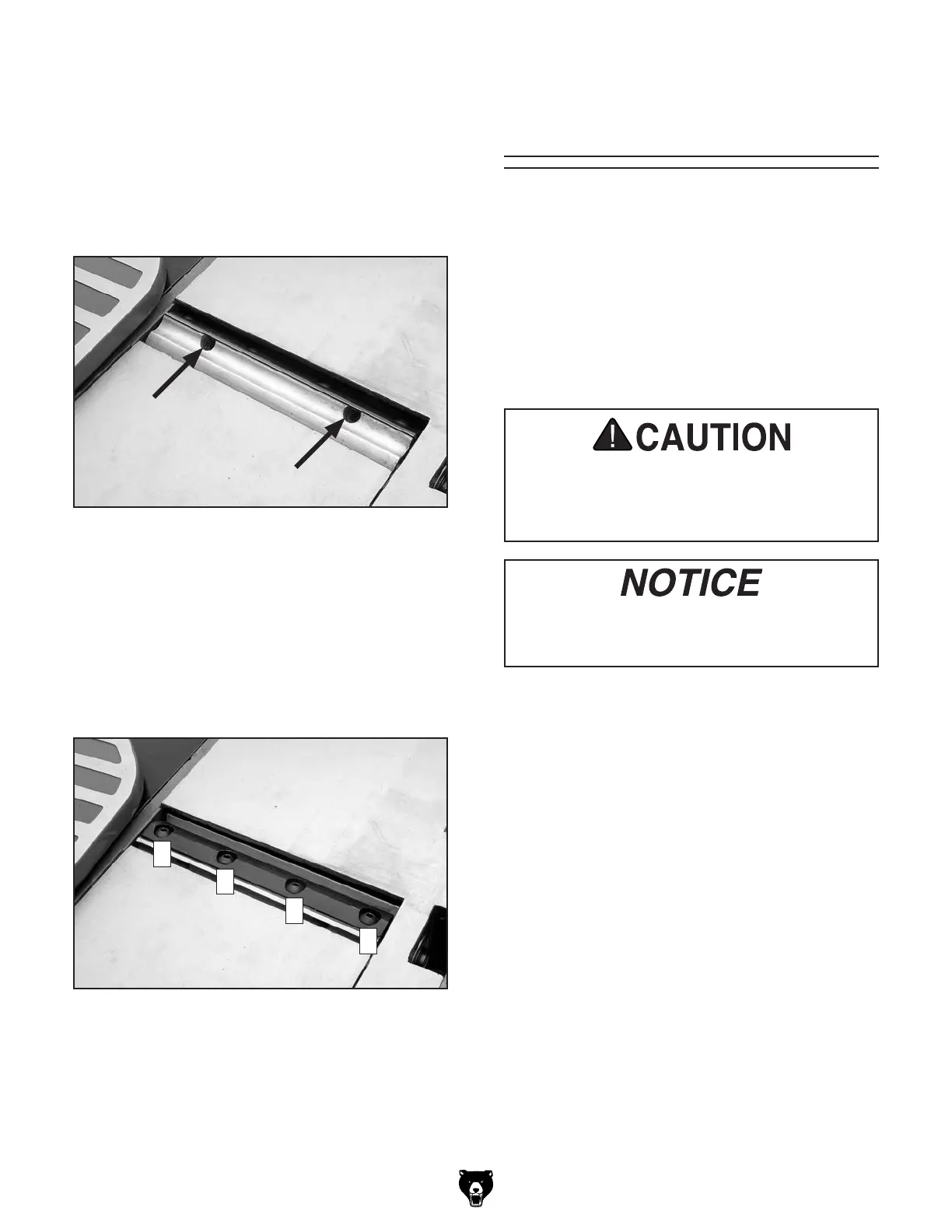

Figure 39. Knife adjustment jack screws.

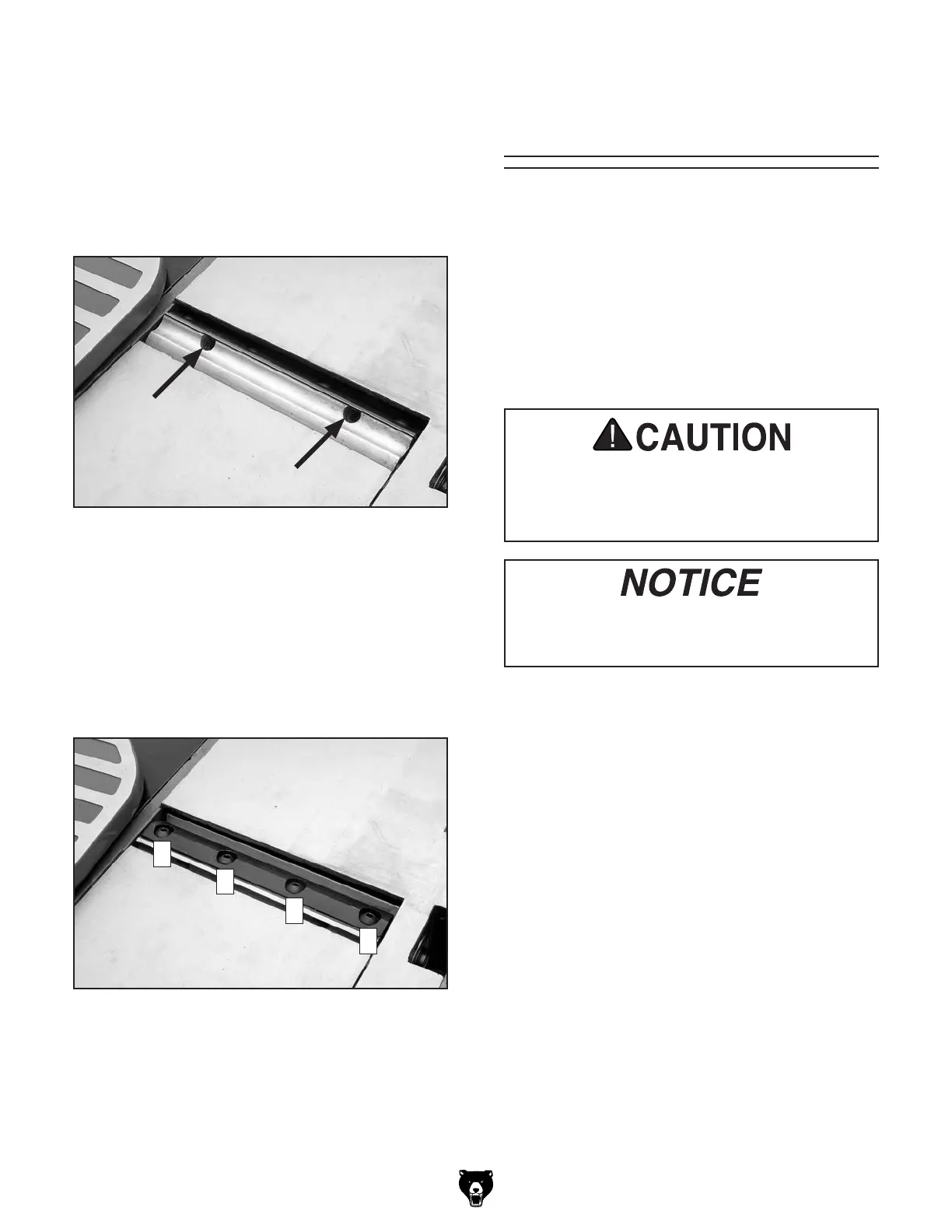

Figure 40. Knife clamp screw tightening

sequence.

Model G0945/G0946/G0947 (Mfd. Since 06/21)

-39-

6. Access (2) jack screws through holes in

cutterhead (see Figure 39). Rotate jack

screws to raise or lower knife. When knife

is set correctly, it will barely touch bottom

of straightedge in each of the straightedge

positions. Snug clamp bolts just tight enough

to hold knife in place, and repeat Steps 5–6

with remaining knife.

7.

Verify knives are set even with outfeed table

by performing Step 3 of Checking Knife

Height on Page 38.

8.

When knife heights are set correctly, fully

tighten each of the knives' clamp screws

according to the tightening sequence shown

in Figure 40.

9.

Install cutterhead guard removed in Step 2

on Page 38 and verify proper operation.

10.

Disengage cutterhead lock before beginning

operations.

1

2

3

4

Checking/Adjusting

Table Parallelism

If the infeed and outfeed tables are not parallel

with the cutterhead and each other, then poor cut-

ting results and kickback can occur.

Table parallelism is factory-set, and should not

normally need to be adjusted when the machine

is new. However, after prolonged use, or if

machine has been jarred during lifting or trans-

portation, it may become necessary to adjust the

table parallelism.

Items Needed Qty

Straightedge 24" ................................................ 1

T-Handle Torx Driver T-25 (G0946/G0947)

....... 1

Hex Wrench 4mm

.............................................. 1

Flat Head Screwdriver

3

⁄8" ................................. 1

Checking Outfeed Table

1. DISCONNECT MACHINE FROM POWER!

2. Loosen (2) button head cap screws secur-

ing cutterhead guard to jointer base, then

remove cutterhead guard.

3.

Remove fence or move it all the way back.

Loading...

Loading...