Appendix

34

Appendix

1. Installation in the USA and Canada

1.1 Electrical connection

1.1.1 Conductors

Use minimum 140/167 °F (60/75 °C) copper conductors only.

1.1.2 Torques

Power terminals

Power terminal: 1.7 ft-lbs

Relay, M2.5: 0.4 ft-lbs

Input control, M2: 0.15 ft-lbs

1.1.3 Line reactors

Max. line reactor size must not exceed 2 mH.

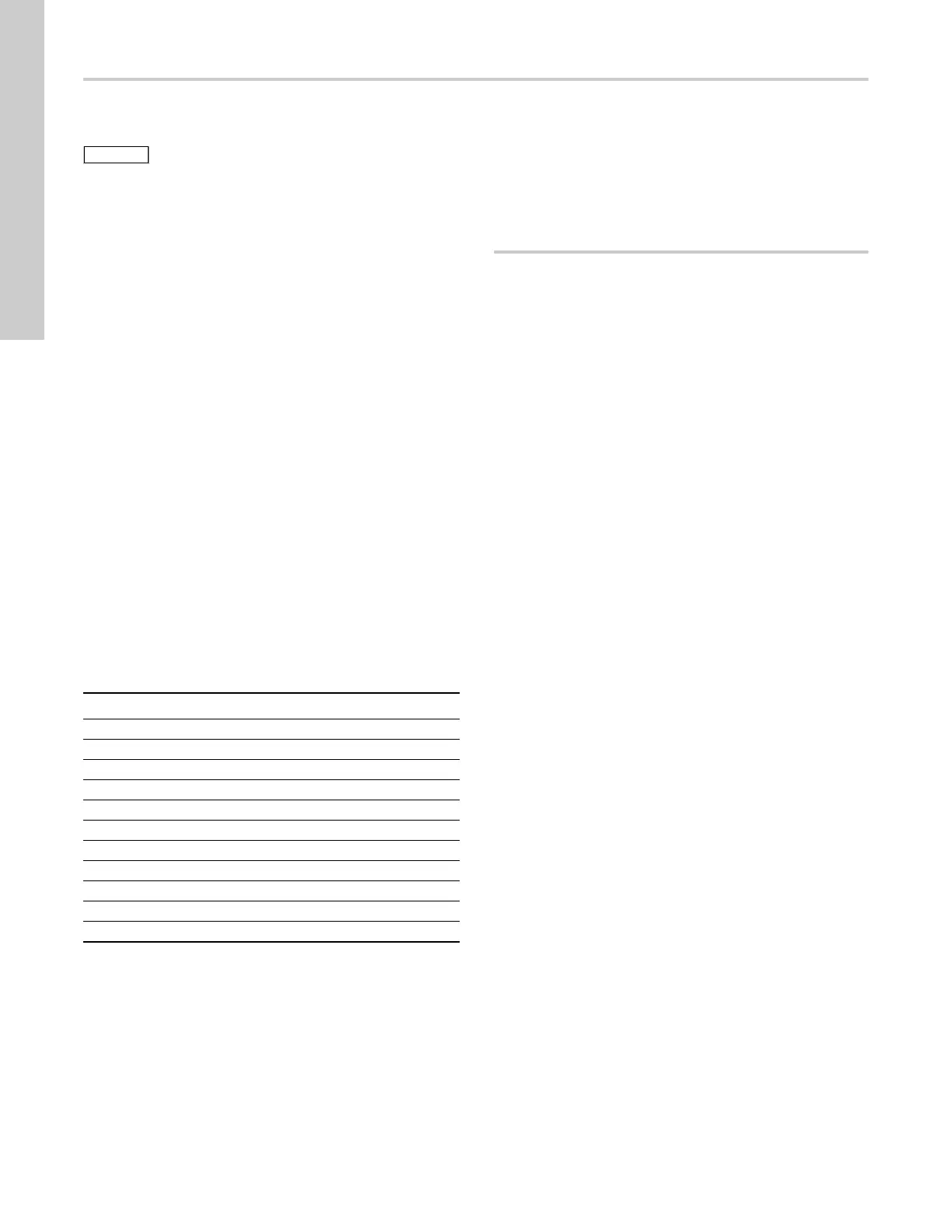

1.1.4 Fuse size/circuit breaker

If a short circuit happens the pump can be used on a power

supply delivering not more than 5000 RMS symmetrical amperes,

480 V maximum.

Fuses

When the pump is protected by fuses they must be rated for

600 V. Maximum sizes are stated in table below.

Up to 10 hp use Class K5 UL Listed fuses. For 10 to 30 hp use

any class UL Listed fuse.

Circuit breaker

When the pump is protected by a circuit breaker, this must be

rated for a maximum voltage of 480 V. The circuit breaker must

be of the "Inverse time" type.

The interrupting rating (RMS symmetrical amperes) must not be

less than the values stated in table below.

USA - hp

1.1.5 Overload protection

Degree of overload protection provided internally by the drive, in

percent of full-load current: 102 %.

1.2 General considerations

For installation in humid environment and fluctuating

temperatures, it is recommended to keep the pump connected to

the power supply continuously. This will prevent moisture and

condensation build-up in the terminal box.

Start and stop must be done via the start/stop digital input

(terminal 2-3).

Subject to alterations.

In order to maintain the UL/cUL approval, follow

these additional installation instructions. The UL

approval is according to UL508C.

2-pole 4-pole Fuse size Circuit breaker type/model

1 1 25 A 25 A / Inverse time

1.5 1.5 25 A 25 A / Inverse time

2 2 25 A 25 A / Inverse time

3 3 25 A 25 A / Inverse time

5 5 40 A 40 A / Inverse time

7.5 – 40 A 40 A / Inverse time

10 7.5 50 A 50 A / Inverse time

15 15 80 A 80 A / Inverse time

20 20 110 A 110 A / Inverse time

25 25 125 A 125 A / Inverse time

30 – 150 A 150 A / Inverse time

Loading...

Loading...