English (US)

6

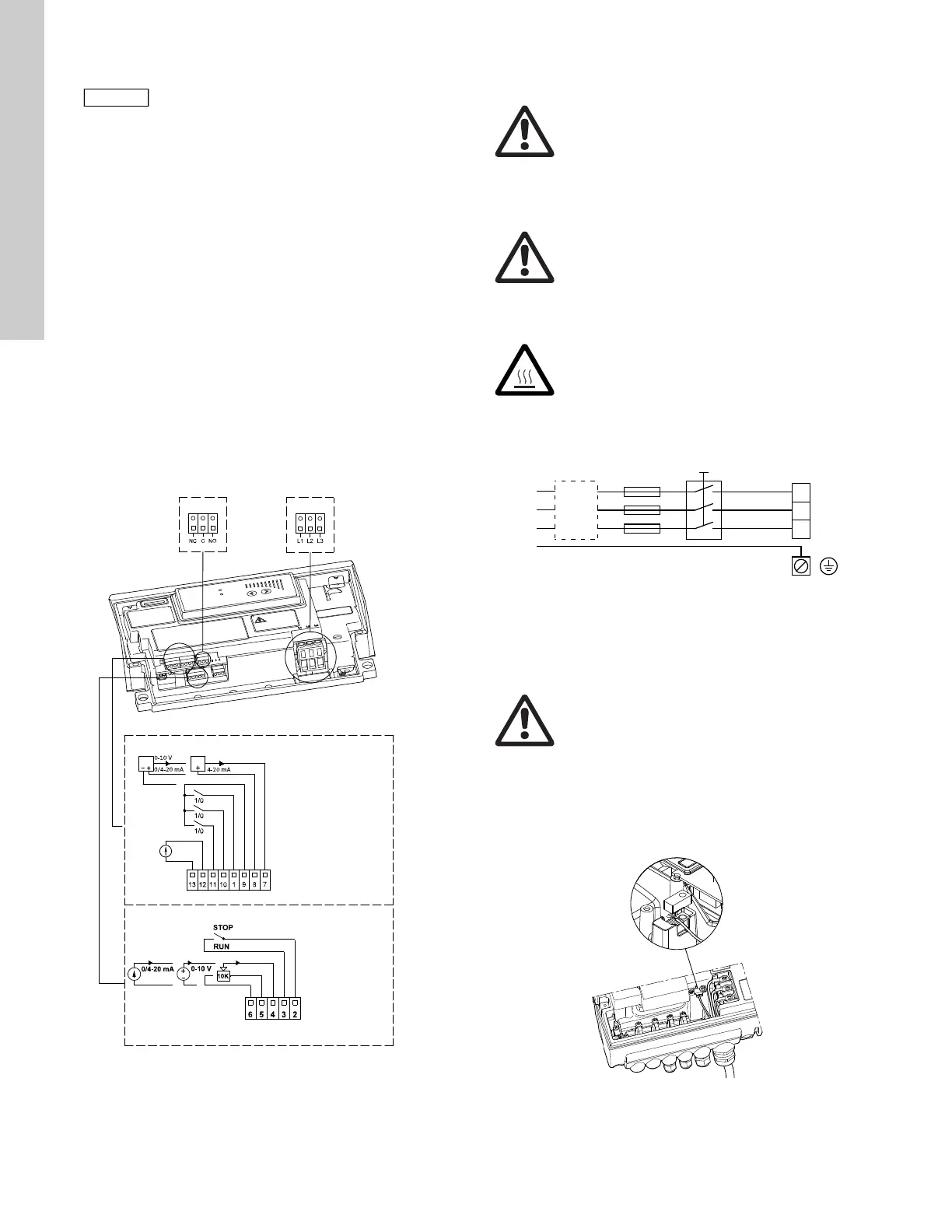

6.2.9 Connections

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop terminals 2 and 3

• digital input terminals 1 and 9

• setpoint input terminals 4, 5 and 6

• sensor input terminals 7 and 8

• GENIbus terminals B, Y and A

All inputs (group 1) are internally separated from the power-

conducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied with protective extra-low voltage

(PELV), thus ensuring protection against electric shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other circuits.

Therefore, the supply voltage or protective extra-low voltage can

be connected to the output as desired.

6.2.10 Three-phase pumps, 1.5 - 10 hp

Group 3: Power supply (terminals L1, L2, L3)

Fig. 5 Connection terminals

A galvanic separation must fulfill the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 60335.

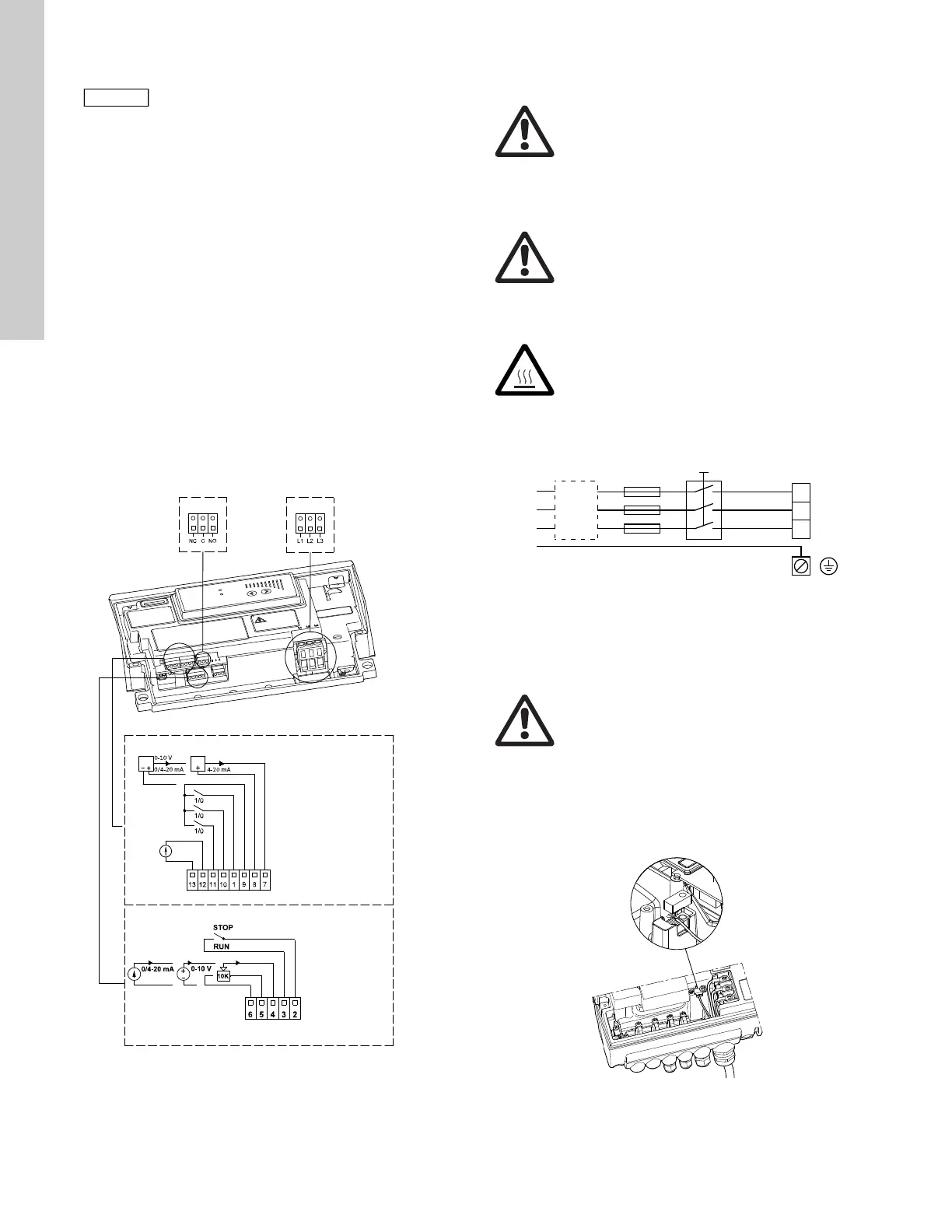

6.3 Three-phase pumps, 15-30 hp

6.3.1 Preparation

Before connecting the E-pump to the power supply, take the

issues illustrated in the figure below into consideration.

Fig. 6 Power supply-connected pump with power switch,

backup fuses, additional protection and protective

grounding

6.3.2 Protection against electric shock - indirect contact

EN 61800-5-1 specifies that the pump must be stationary and

installed permanently when the leakage current is > 10 mA.

One of the following requirements must be fulfilled:

• A single protective ground lead (7 AWG minimum copper)

Fig. 7 Connection of a single protective ground lead using

one of the leads of a 4-core power cable

(7 AWG minimum)

If no external on/off switch is connected,

connect terminals 2 and 3 using a short wire.

TM05 2985 0812

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

Group 2

Group 3

13: GND (frame)

12: Analog output

11: Digital input 4

10: Digital input 3

1: Digital input 2

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

Warning

The user or the installer is responsible for the

installation of correct grounding and protection

according to current national and local

standards. All operations must be carried out by

qualified personnel.

Warning

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance that the signal relay may be

connected to an external supply which is still

connected when the power supply is

disconnected.

Warning

The surface of the terminal box may be above

158 °F (70 °C) when the pump is operating.

TM00 9270 4696

Warning

The pump must be grounded in accordance with

national regulations.

As the leakage current of 15-30 hp motors is

> 10 mA, take extra precautions when grounding

these motors.

TM04 3021 3508

Loading...

Loading...