Terminal Type Function

Y GENIbus, Y GENIbus, GND

B GENIbus, B GENIbus, B (-)

3 GND Ground

15 +24 V Supply

8 +24 V Supply

26 +5 V

Supply to potentiometer and

sensor

23 GND Ground

25 GDS TX

Grundfos Digital Sensor

output

24 GDS RX Grundfos Digital Sensor input

7 AI2

Analog input:

0-20 mA / 4-20 mA

0.5 - 3.5 V / 0-5 V / 0-10 V

Related information

11.6 Other technical data

6.6 Signal cables

• Use screened cables with a cross-sectional area of minimum 28

AWG and maximum 16 AWG for the external on/off switch,

digital inputs and setpoint signals.

• Connect the screens of the cables to the frame at both ends

with good connection. The screens must be as close as

possible to the terminals. See the figure below.

TM021325

Stripped cable with screen and wire connections

• Always tighten screws for frame connections whether a cable is

fitted or not.

• The wires in the motor terminal box must be as short as

possible.

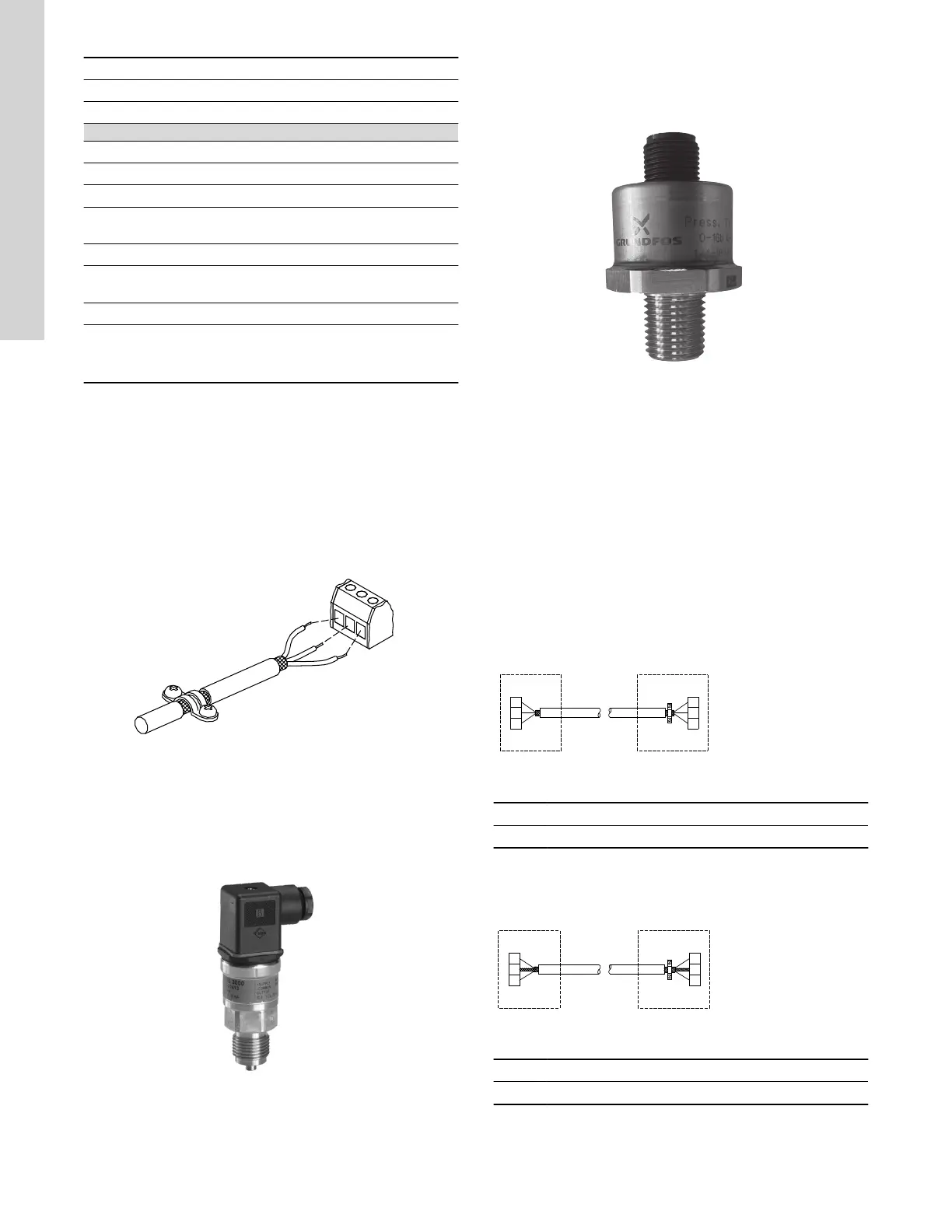

Connection of Danfoss pressure sensor MBS3000 to E-pump

TM051533_2911

MBS3000 pressure sensor

Use screened cables with a cross-sectional area of minimum 28

AWG and maximum 16 AWG.

The blue wire of the pressure sensor is connected to the #4

terminal of the E-pump. The brown wire of the pressure sensor is

connected to the #8 terminal of the E-pump.

Connection of Grundfos pressure sensor ISP44 to E-pump

TM083396

ISP44 pressure sensor

Use unscreened cables with a cross-sectional area of minimum 28

AWG and maximum 16 AWG.

The blue wire of the pressure sensor is connected to the #4

terminal of the E-pump. The brown wire of the pressure sensor is

connected to the #8 terminal of the E-pump.

6.7 Bus connection cable

New installations

For the bus connection, use a screened 3-core cable with a cross-

sectional area of minimum 28 AWG and maximum 16 AWG.

If the motor is connected to a unit with a cable clamp which is

identical to the one on the motor, connect the screen to this cable

clamp.

If the unit has no cable clamp leave the screen unconnected at this

end. See the figure below.

TM053973

Connection with screened 3-core cable

Pos. Description

1 Motor

Replacing a motor

• If a 2-core cable is used in the installation, connect it as shown

in the figure below.

TM054035

Connection with screened 2-core cable

Pos. Description

1 Motor

• If a screened 3-core cable is used in the installation, follow the

instructions in the section on the new installations above.

18

English (US)

Loading...

Loading...