7

System limits

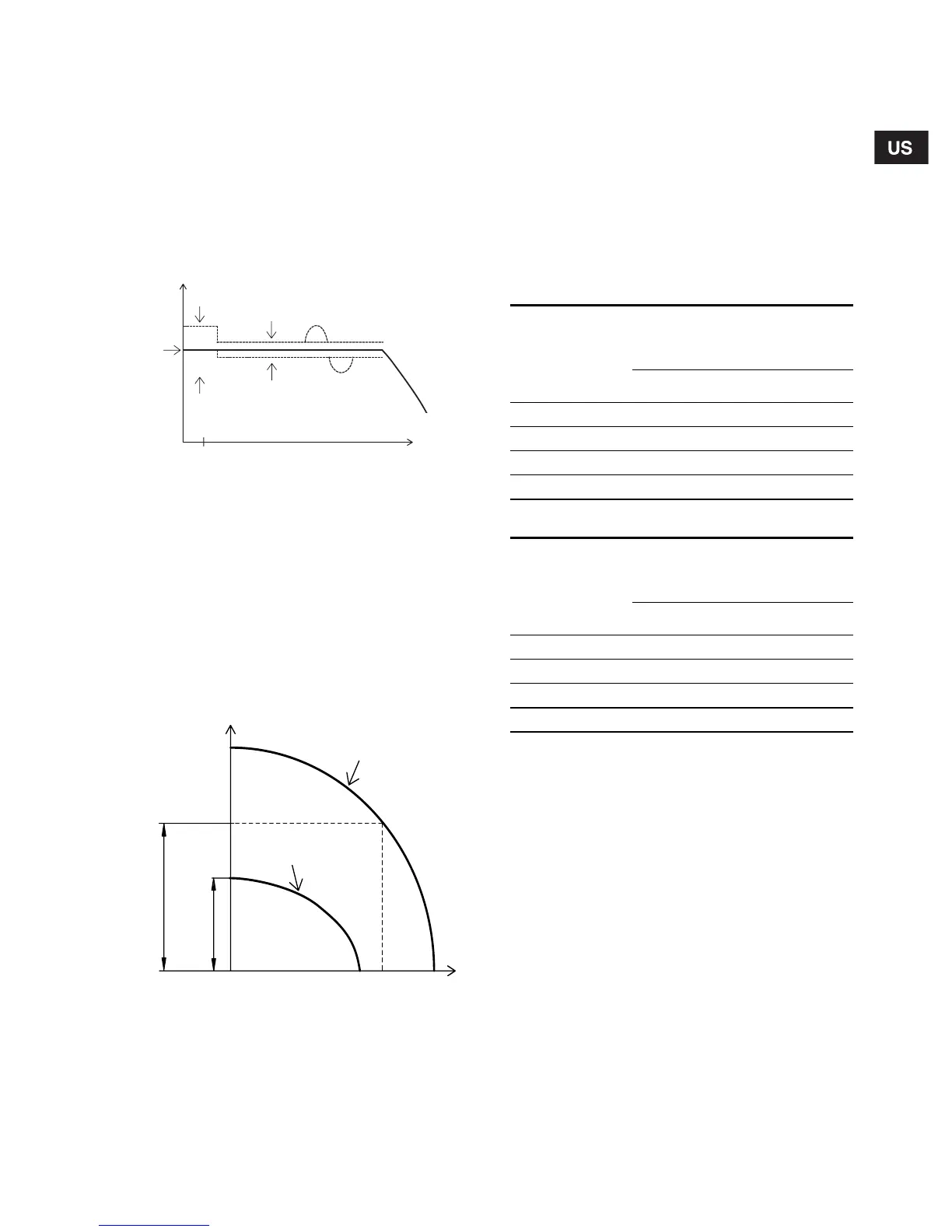

Even though the CU 321 is controlling the pressure

within ±3 psi, larger pressure variations may occur in

the system. If the consumption is suddenly changed,

e.g. if a tap is opened, the water must start flowing

before the pressure can be made constant again.

Such dynamic variations depend on the pipework,

but, typically ±7 psi. If the desired consumption is

higher than the quantity the pump is able to deliver at

the desired pressure, the pressure follows the pump

curve as illustrated in the far right of fig. 3.

Fig. 3 Pressure as a function of the flow

Note: The pressure may fluctuate up to 20 psi below

the setpoint when the pump is started in a high-

demand situation. A larger diaphragm tank will mini-

mize this effect.

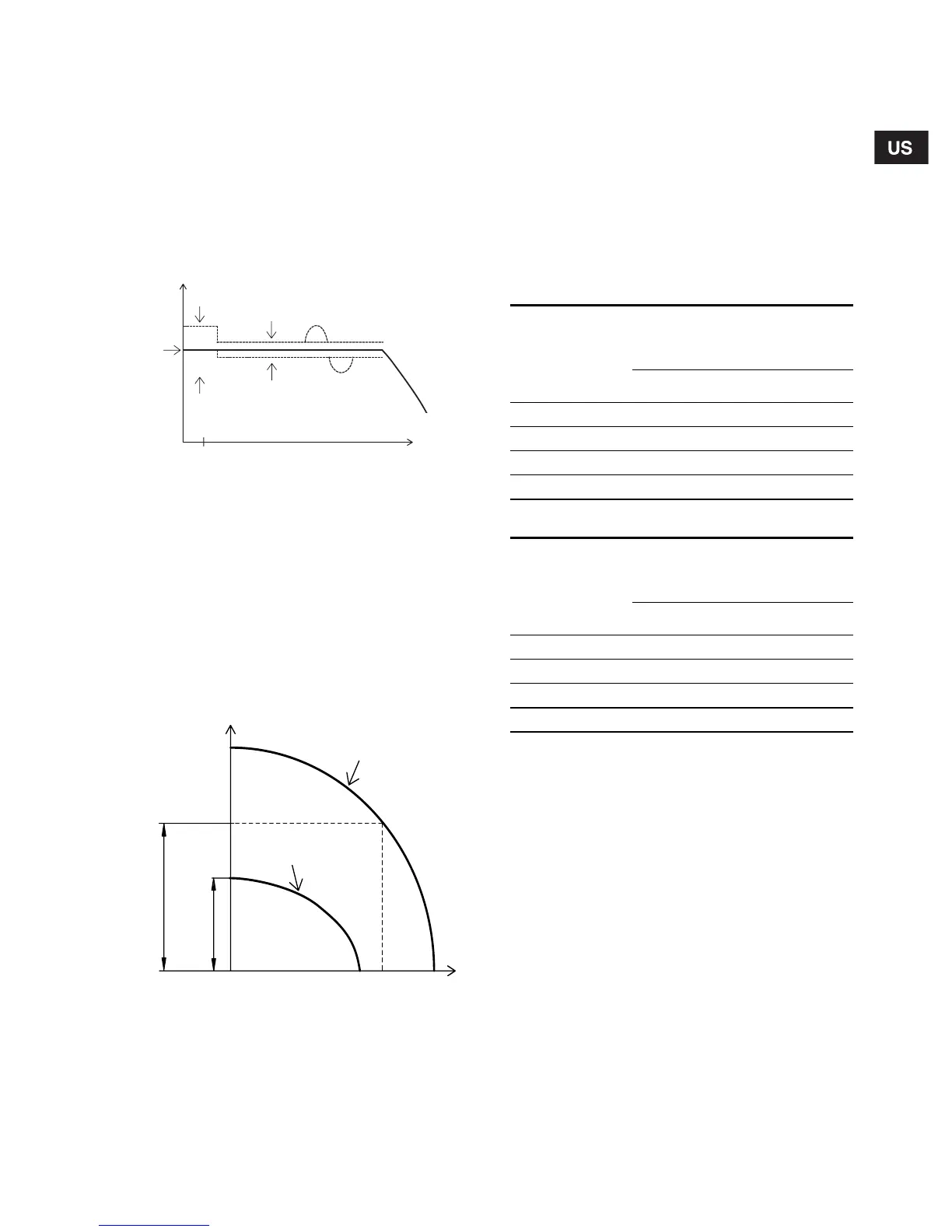

1.4 System sizing

To ensure the correct function of the system, it is

important that the pump is of the right type.

During operation, the CU 321 controls the pump

speed within the range from 1,500 to 3,600 rpm,

see fig. 4.

Fig. 4 Pump curve (sizing)

Recommended guidelines for system sizing:

The following must be fulfilled:

• Min. head at no flow < static head + system

pressure.

Comment: If this is not fulfilled, the pressure may

exceed the pressure set on the CU 321.

• Max. head at rated flow > dynamic head + system

pressure.

Comment: If this is not fulfilled, the pressure may

fall below the pressure set on the CU 321.

Max. head at rated flow and min. head at no flow can

be found in the table below:

3 hp:

5 hp:

TM03 3601 0406TM01 8547 0400

Controlling

±3 psi

Dynamic

variations

±7 psi

Pressure

Start at

setpoint

Stop

+7 psi

gpm

0.8

Loading...

Loading...