27

7.4 System-related faults

7.4.1 Voltage drop

“mains drop”

The PMU 2000 is monitored for voltage drops. Voltage drops

which persist for more than one minute will be indicated as faults.

After restarting of the PMU 2000, the time when the voltage drop

occurred and the time when it disappeared are displayed and

stored. If the voltage drop influences a PFU 2000 only, it is dis-

played in the PMU 2000 as a communication fault.

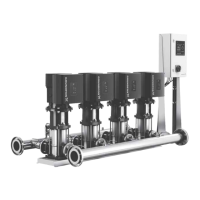

8. Maintenance

8.1 Maintenance of booster set

8.1.1 Pumps

Pump bearings and shaft seal are maintenance-free.

If the pump is to be drained for a long period of inactivity, remove

one of the coupling guards to inject a few drops of silicone oil on

the shaft between the pump head and the coupling. This will pre-

vent the shaft seal faces from sticking.

8.1.2 Motor bearings

Motors which are not fitted with grease nipples are maintenance-

free.

Motors fitted with grease nipples should be lubricated with a high-

temperature lithium-based grease, see the instructions on the fan

cover of GRUNDFOS motors.

In the case of seasonal operation (motor is idle for more than

6 months of the year), it is recommended to grease the motor

when the pump is taken out of operation.

8.1.3 Frost protection

Pumps which are not being used during periods of frost should be

drained to avoid damage.

Drain the pump by loosening the vent screw in the pump head

and by removing the drain plug from the base.

Do not tighten the vent screw and replace the drain plug until the

pump is to be used again.

8.2 Maintenance of the Control 2000 F

The Control 2000 F must be kept clean and dry. Clean the filters

for the ventilation regularly.

Before starting work on the pumps, make sure that

the electricity supply has been switched off and that it

cannot be accidentally switched on.

Care must be taken to ensure that the escaping wa-

ter does not cause injury to persons or damage to the

motor or other components. In hot water installations,

special attention should be paid to the risk of injury

caused by scalding hot water.

Loading...

Loading...