29

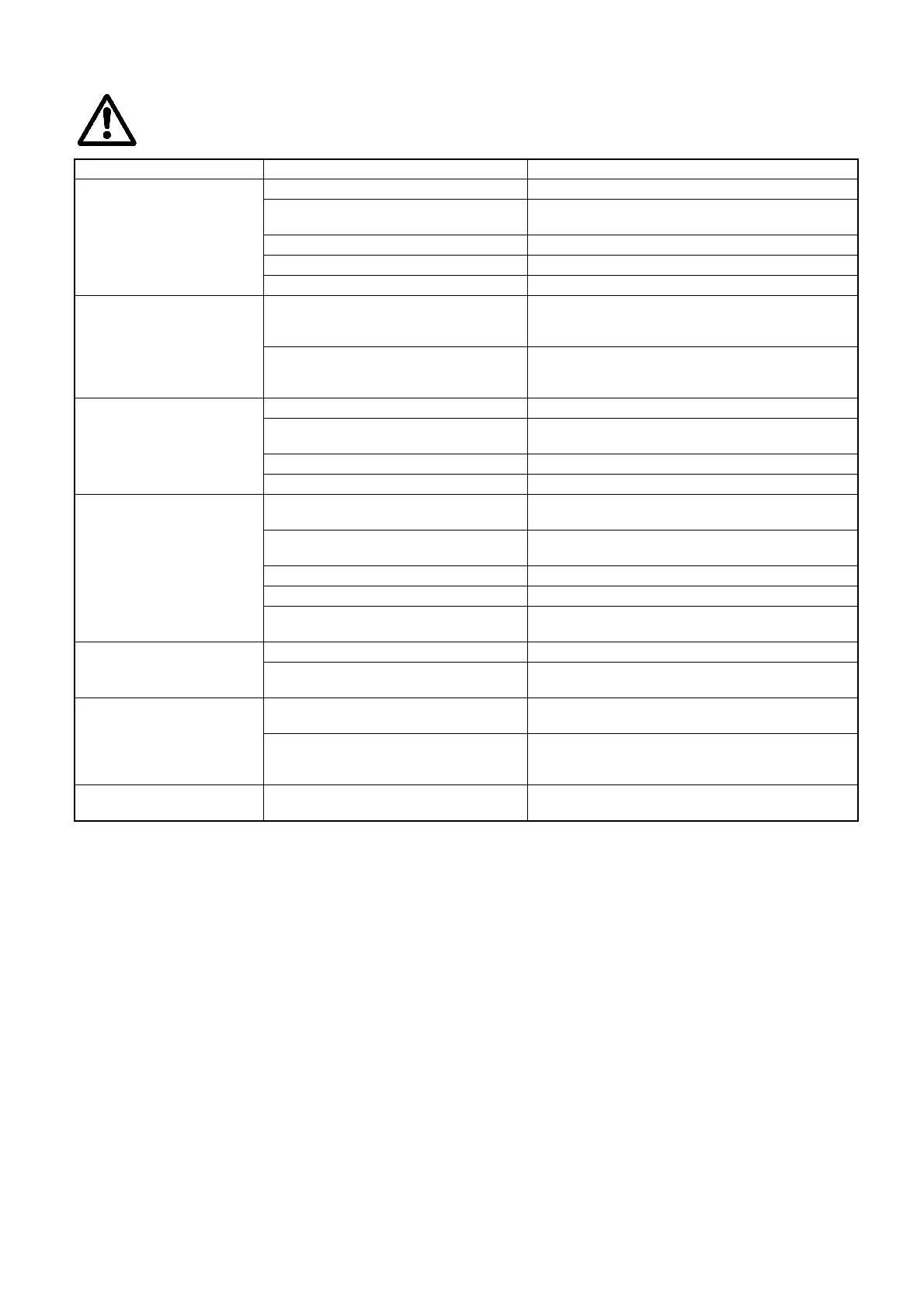

10. Fault finding chart

Before making any connections in pumps, terminal

boxes or controllers, the electricity supply must be

switched off.

Fault Cause Remedy

1. Motor does not run when

started.

a) Electricity supply disconnected. Connect the electricity supply.

b) Automatic circuit breakers cut out. Correct the fault and cut in the automatic circuit

breakers.

c) Motor protection activated. Correct the fault and reactivate the motor protection.

d) Fuse in the PFU 2000 defective. Replace the fuse.

e) Motor defective. Repair/replace the motor.

2. Motor starts, but stops

immediately afterwards.

a) Fault in pressure transmitter. Replace the pressure transmitter. Transmitters with

0-20 mA or 4-20 mA output signals are monitored by

the PFU 2000.

b) Dry running or no pre-pressure.

The operating pressure is not reached.

Check the supply of water to the pump. When the pre-

pressure has been reestablished, the pump will restart

after 15 secs. and the fault indication will remain.

3. Unstable water delivery

from Hydro 2000 F

(applies only to very low

consumption).

a) Pre-pressure too low. Check the suction pipe and possible suction strainer.

b) Suction pipe/pumps partly blocked

by impurities.

Clean the suction pipe/pumps.

c) Pumps suck air. Check the suction pipe for leakages.

d) Pressure transmitter defective. Replace the transmitter.

4. Pumps are running, but

deliver no water.

a) Suction pipe/pumps blocked by

impurities.

Clean the suction pipe/pumps.

b) Non-return valve blocked in closed

position.

Clean the non-return valve. The non-return valve must

move freely.

c) Suction pipe leaky. Check the suction pipe for leakages.

d) Air in suction pipe/pumps. Vent the pumps. Check the suction pipe for leakages.

e) Motors running with the wrong

direction of rotation.

Change the direction of rotation.

5. Leakage from the shaft

seal.

a) Shaft seal defective. Replace the shaft seal.

b) Height adjustment of pump shaft

inaccurate.

Readjust the shaft height.

6. Noise. a) The pumps are cavitating. Clean the suction pipe/pumps and possibly the suction

strainer.

b) The pumps do not rotate freely

(frictional resistance) due to inaccurate

height adjustment of the pump shaft.

Readjust the shaft height.

7. Very frequent starts and

stops.

a) Wrong diaphragm tank precharge

pressure.

Check the diaphragm tank precharge pressure.

Loading...

Loading...