7

4. Installation

Arrows on the pump housing indicate the liquid flow

direction through the pump.

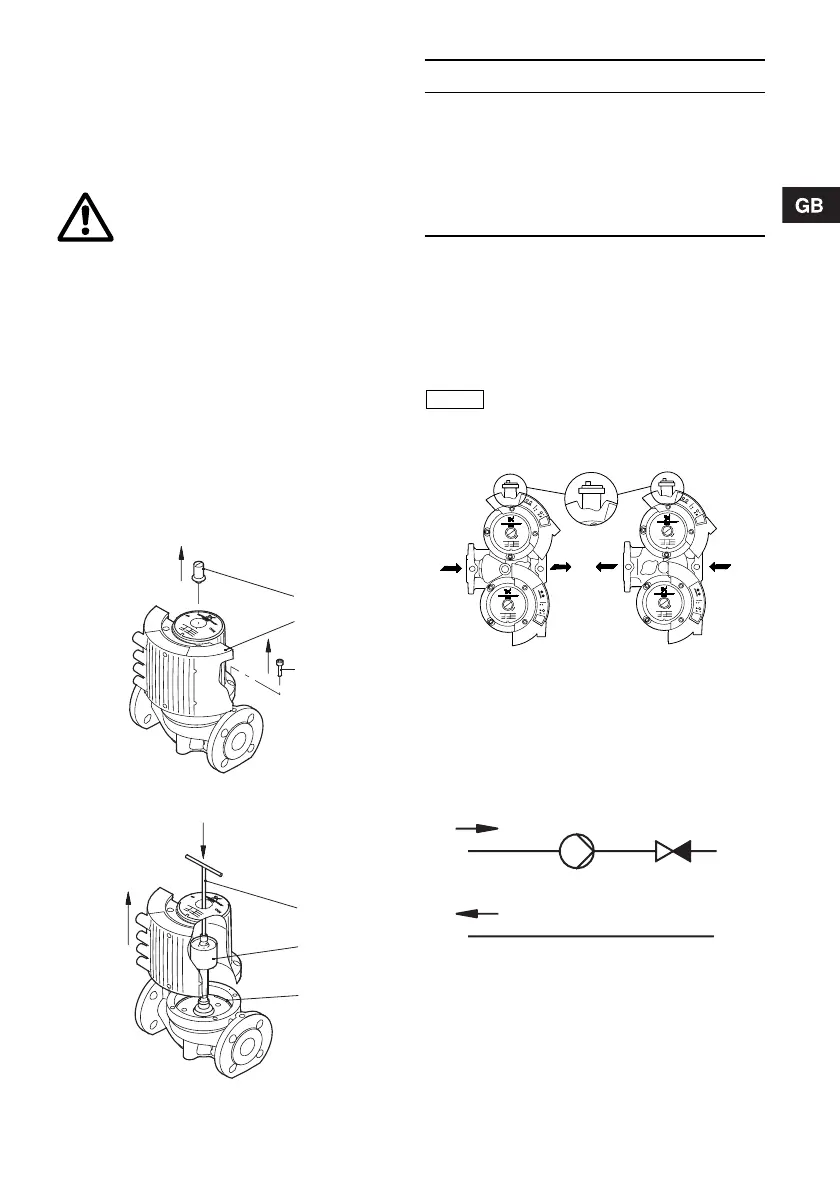

4.1 Changing the control box position

Change the control box position as follows:

1. Remove the inspection screw (1) and the four

screws (2) in the stator housing, see fig. 1.

2. Lift off the stator housing (3). Keep the rotor (4) in

place using a suitable tool, e.g. a T-key (M8) (5),

see fig. 2.

3. Check that the O-ring (6) is intact.

A defective O-ring must be replaced.

4. Hold the stator housing/control box (3) in the

desired position.

5. Lower the stator housing over the rotor.

Keep the rotor in place as described in point 2.

6. Fit and tighten the four screws and the inspection

screw.

Fig. 1 Removing the control box

Fig. 2 Changing the control box position

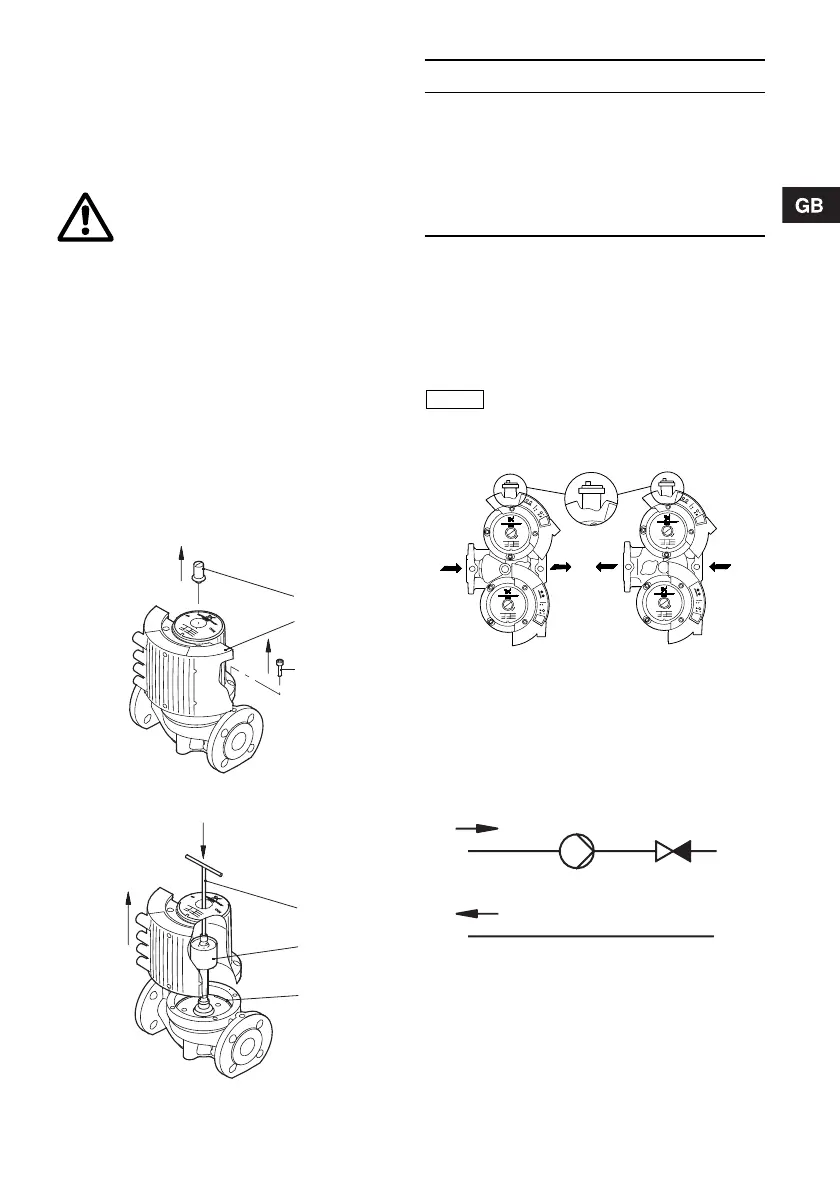

4.2 Twin-head pumps

Twin-head pumps are supplied fitted with a GENI

module on each control box. The modules are

connected via a cable. The modules determine the

operating mode of the pump, see section

7.12.1 Control of twin-head pumps.

The automatic air vent is not supplied with the pump.

Fig. 3 Automatic air vent

4.3 Non-return valve

If a non-return valve is fitted in the pipe system, see

fig. 4, it must be ensured that the set minimum

discharge pressure of the pump is always higher

than the closing pressure of the valve. This is

especially important in proportional-pressure control

mode (reduced head at low flows).

Fig. 4 Non-return valve

Warning

Before any dismantling of the pump,

the system must be drained or the

isolating valves on either side of the

pump must be closed as the pumped

liquid may be scalding hot and under

high pressure.

TM02 5506 3402TM02 5507 3402

2

3

1

5

4

6

Pos. Description

1 Inspection screw

2Screw

3 Stator housing/control box

4 Rotor

5T-key

6 O-ring

Caution

Twin-head pumps mounted in

horizontal pipes must be fitted with an

automatic air vent (Rp 1/4) in the upper

part of the pump housing, see fig. 3.

TM03 8831 2607TM02 0640 0301

Loading...

Loading...