English (GB)

17

5. Handling and storing the product

Always lift directly on the pump head or the cooling fins when

handling the pump. For large pumps, it may be necessary to use

lifting equipment. See section 2.3 Lifting the product.

6. Product introduction

6.1 Product description

Grundfos MAGNA1 is a complete range of circulator pumps with

integrated controller enabling adjustment of pump performance to

the actual system requirements. In many systems, this reduces

the power consumption considerably, reduces noise from

thermostatic radiator valves and similar fittings and improves the

control of the system.

You can set the desired head on the operating panel.

6.2 Intended use

The pump is designed for circulating liquids in the following

systems:

• heating systems

• domestic hot-water systems

• air-conditioning and cooling systems.

You can also use the pump in the following systems:

• ground-source heat-pump systems

• solar-heating systems.

6.3 Pumped liquids

The pump is suitable for thin, clean, non-aggressive and

non-explosive liquids, not containing solid particles or fibres that

may attack the pump mechanically or chemically.

In heating systems, the water must meet the requirements of

accepted standards on water quality in heating systems, for

example the German standard VDI 2035.

The pump is also suitable for domestic hot-water systems.

We strongly recommend that you use stainless-steel pumps in

domestic hot-water applications to avoid corrosion.

In domestic hot-water systems, we recommend that you use the

pump only for water with a degree of hardness lower than

approximately 14 °dH.

In domestic hot-water systems, we recommend that you keep the

liquid temperature below 65 °C to eliminate the risk of lime

precipitation.

6.3.1 Glycol

You can use the pump for pumping water-ethylene-glycol

mixtures up to 50 %.

Example of a water-ethylene-glycol mixture:

Maximum viscosity: 50 cSt ~ 50 % water and 50 % glycol mixture

at -10 °C.

The pump has a power-limiting function that protects it against

overload.

The pumping of glycol mixtures affects the maximum curve and

reduces the performance, depending on the

water-ethylene-glycol mixture and the liquid temperature.

To prevent the glycol mixture from degrading, avoid temperatures

exceeding the rated liquid temperature and minimise the

operating time at high temperatures.

Clean and flush the system before you add the glycol mixture.

To prevent corrosion or lime precipitation, maintain the glycol

mixture regularly. If further dilution of the supplied glycol is

required, follow the glycol supplier's instructions.

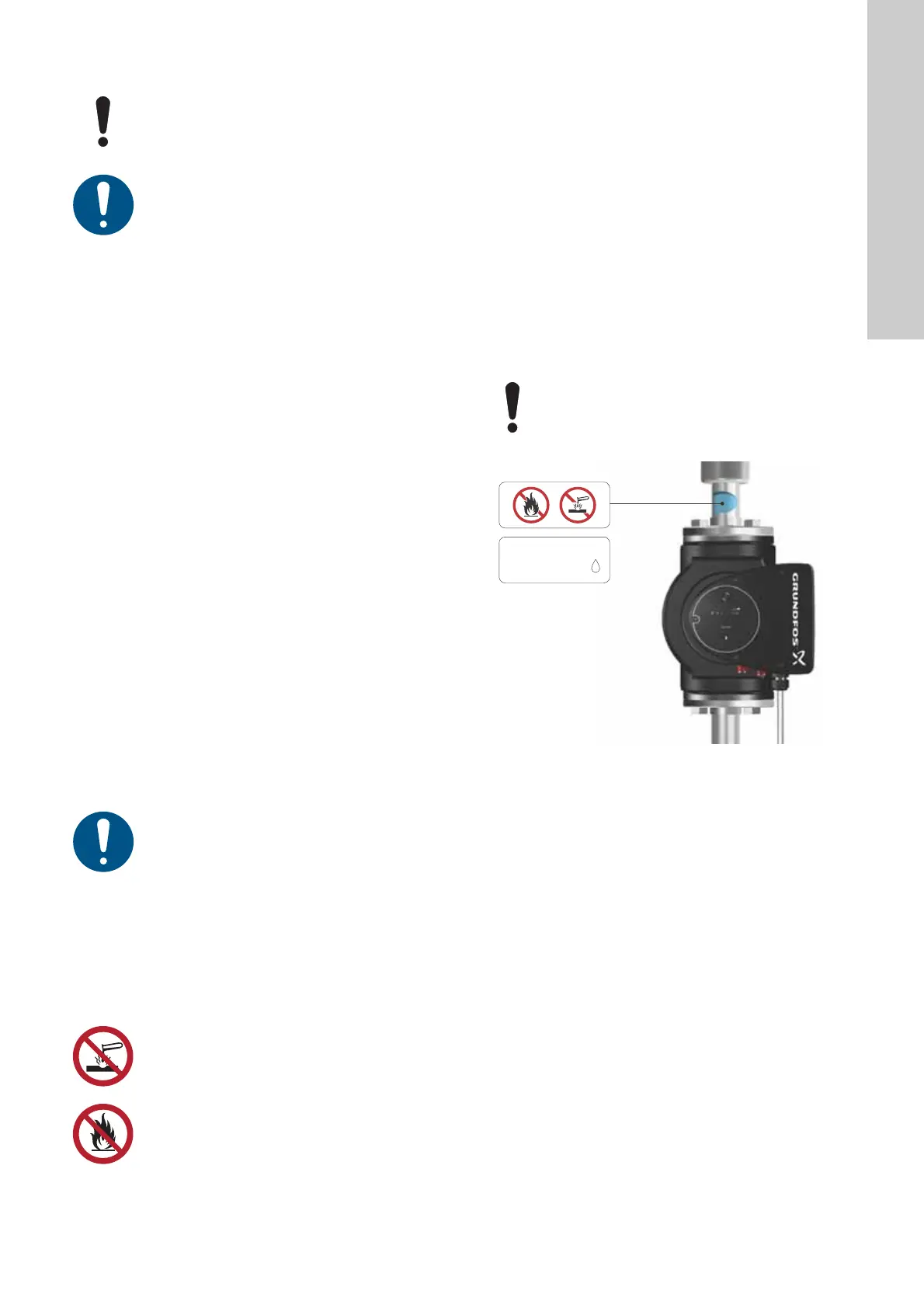

Fig. 19 Pumped liquids

If the pump is not used during periods of frost, add

antifreeze or let the pump run in regular intervals to

prevent frost bursts.

Observe local regulations concerning limits for

manual lifting or handling.

Observe local regulations regarding pump-housing

material.

Do not pump aggressive liquids.

Do not pump flammable, combustible or explosive

liquids.

Additives with a density or kinematic viscosity higher

than water reduces the hydraulic performance.

TM06 8055 0717

Loading...

Loading...