English (GB)

9

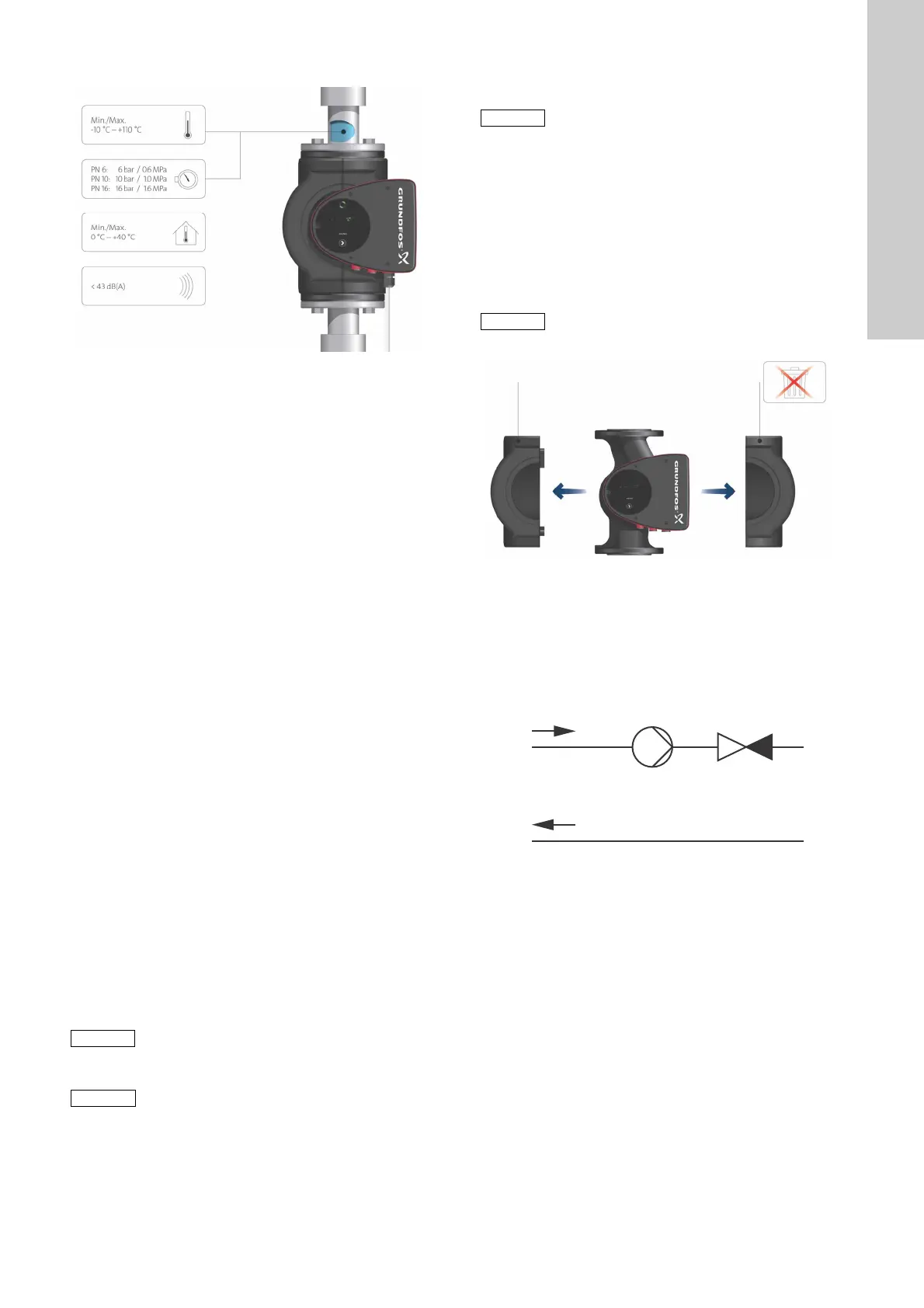

2.3 Operating conditions

Fig. 3 Operating conditions

2.3.1 Liquid temperature

See fig. 3, pos. 1.

Continuously: -10 to +110 °C.

2.3.2 System pressure

See fig. 3, pos. 2.

The maximum permissible system pressure is stated on the pump

nameplate. See fig. 6.

2.3.3 Test pressure

The pumps can withstand test pressures as indicated in

EN 60335-2-51. See below.

• PN 6: 7.2 bar

• PN 10: 12 bar

• PN 6/10: 12 bar

• PN 16: 19.2 bar.

During normal operation, the pump should not be used at higher

pressures than those stated on the nameplate. See fig. 6.

Pumps tested with water containing anti-corrosive additives are

taped on the suction and discharge ports to prevent residual test

water from leaking into the packaging. Remove the tape before

installing the pump.

The pressure test has been made with water containing

anti-corrosive additives at a temperature of +20 °C.

2.3.4 Ambient temperature

See fig. 3, pos. 3.

0 to +40 °C.

The control box is air-cooled. Therefore, it is important that the

maximum permissible ambient temperature is not exceeded

during operation.

During transport: -30 to +55 °C.

2.3.5 Sound pressure level

See fig. 3, pos. 4.

The sound pressure level of the pump is lower than 43 dB(A).

2.4 Frost protection

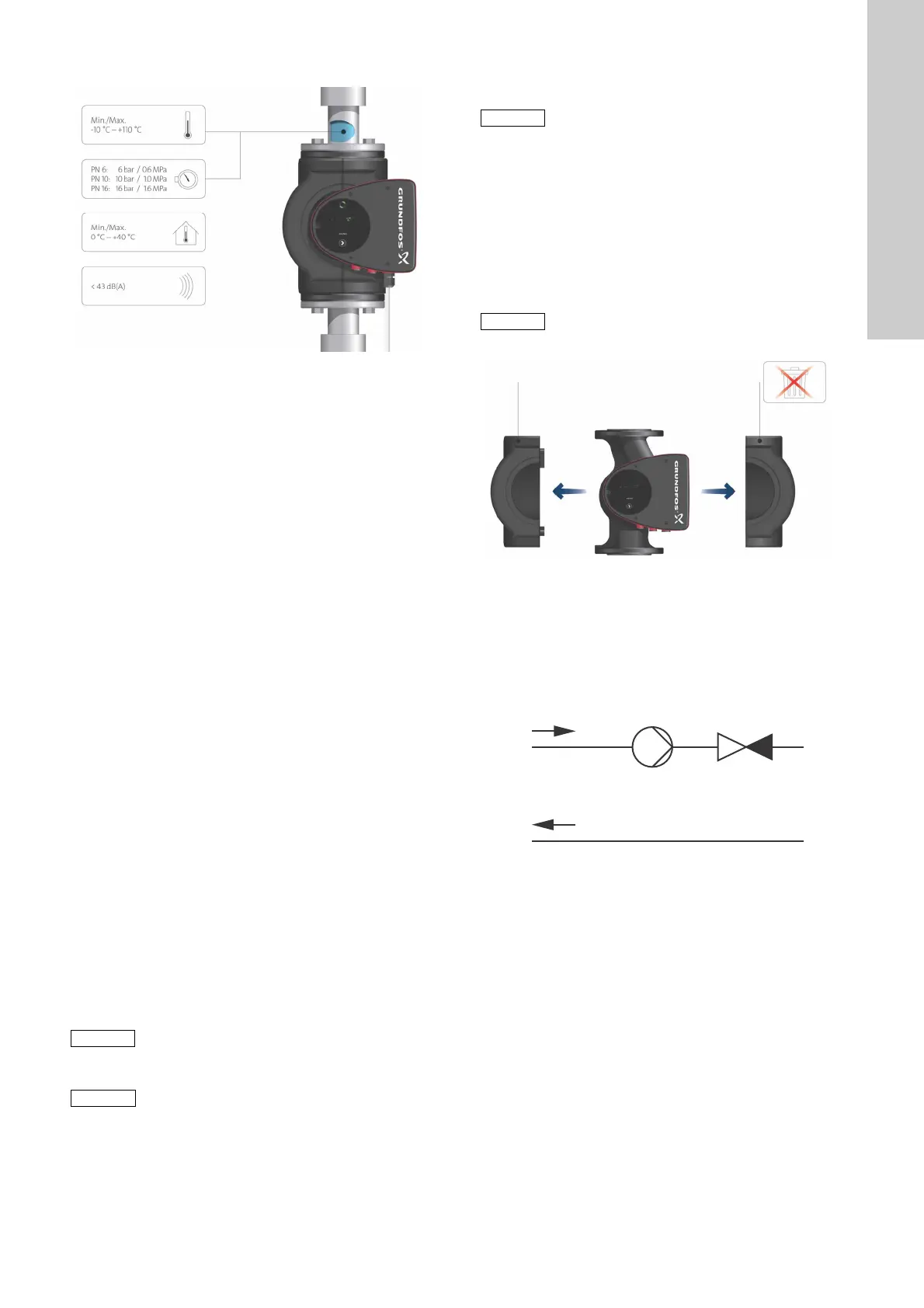

2.5 Insulating shells

Insulating shells are available for single-head pumps only.

The heat loss from the pump and pipework can be reduced by

insulating the pump housing and the pipework. See fig. 4.

• Insulating shells for pumps in heating systems are supplied

with the pump.

• Insulating shells for pumps in air-conditioning and cooling

systems (down to -10 °C) are available as accessories and

must be ordered separately. See section 11.1 Insulating kits

for air-conditioning and cooling systems.

The fitting of insulating shells will increase the pump dimensions.

Fig. 4 Insulating shells

2.6 Non-return valve

If a non-return valve is fitted in the pipe system (fig. 5), ensure

that the set minimum discharge pressure of the pump is always

higher than the closing pressure of the valve. This is especially

important in proportional-pressure control mode (reduced head at

low flow). The first non-return valve is included in the pump

setting as the minimum setpoint is 1.0 metre.

Fig. 5 Non-return valve

TM05 5511 3812

If the pump is not used during periods of frost,

necessary steps must be taken to prevent frost

bursts.

Additives with a density and/or kinematic

viscosity higher than those/that of water will

reduce the hydraulic performance.

Limit the heat loss from the pump housing and

pipework.

Pumps for heating systems are factory-fitted with

insulating shells. Remove the insulating shells

before installing the pump.

TM05 5512 3812TM05 3055 0912

Loading...

Loading...