English (GB)

5

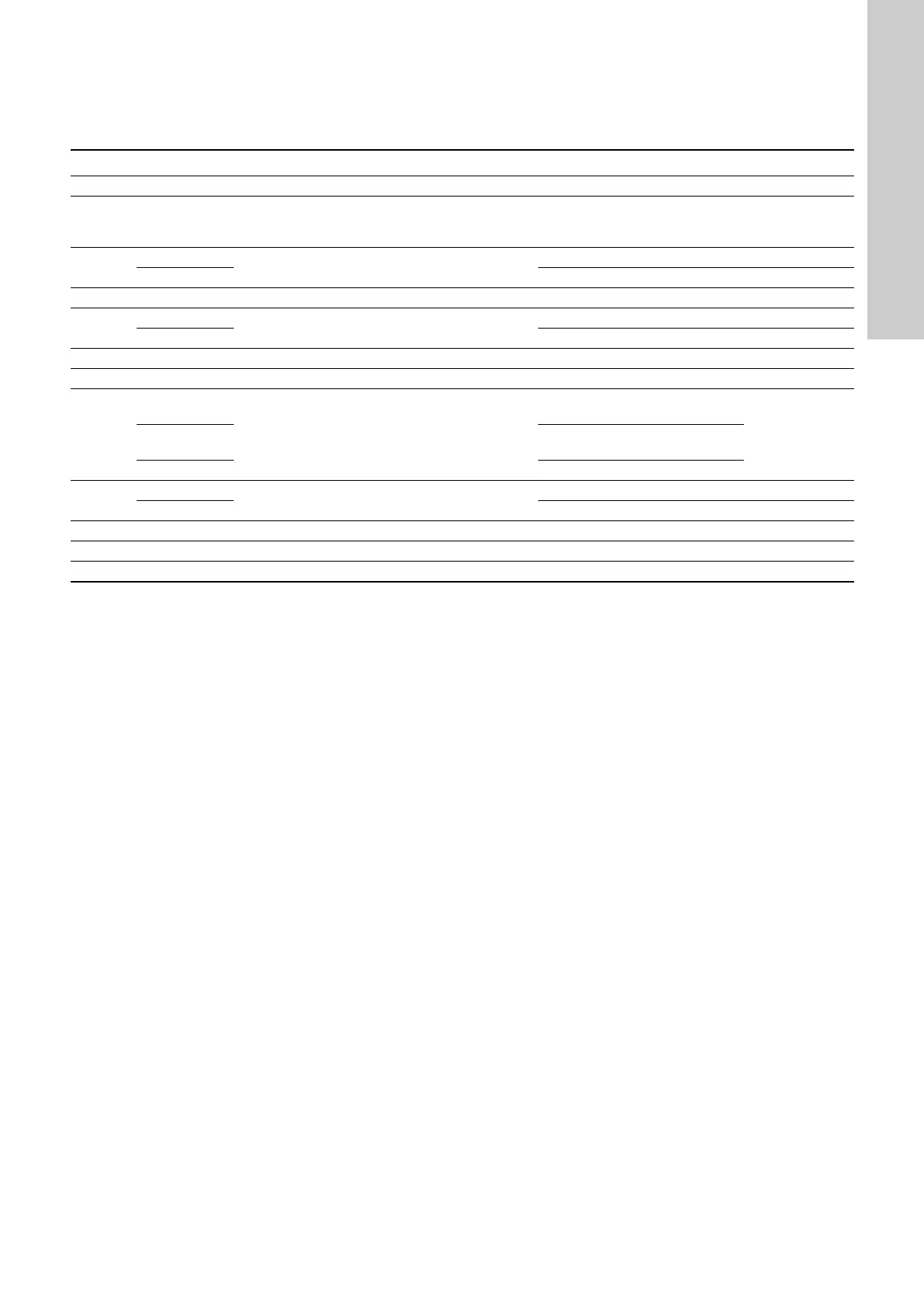

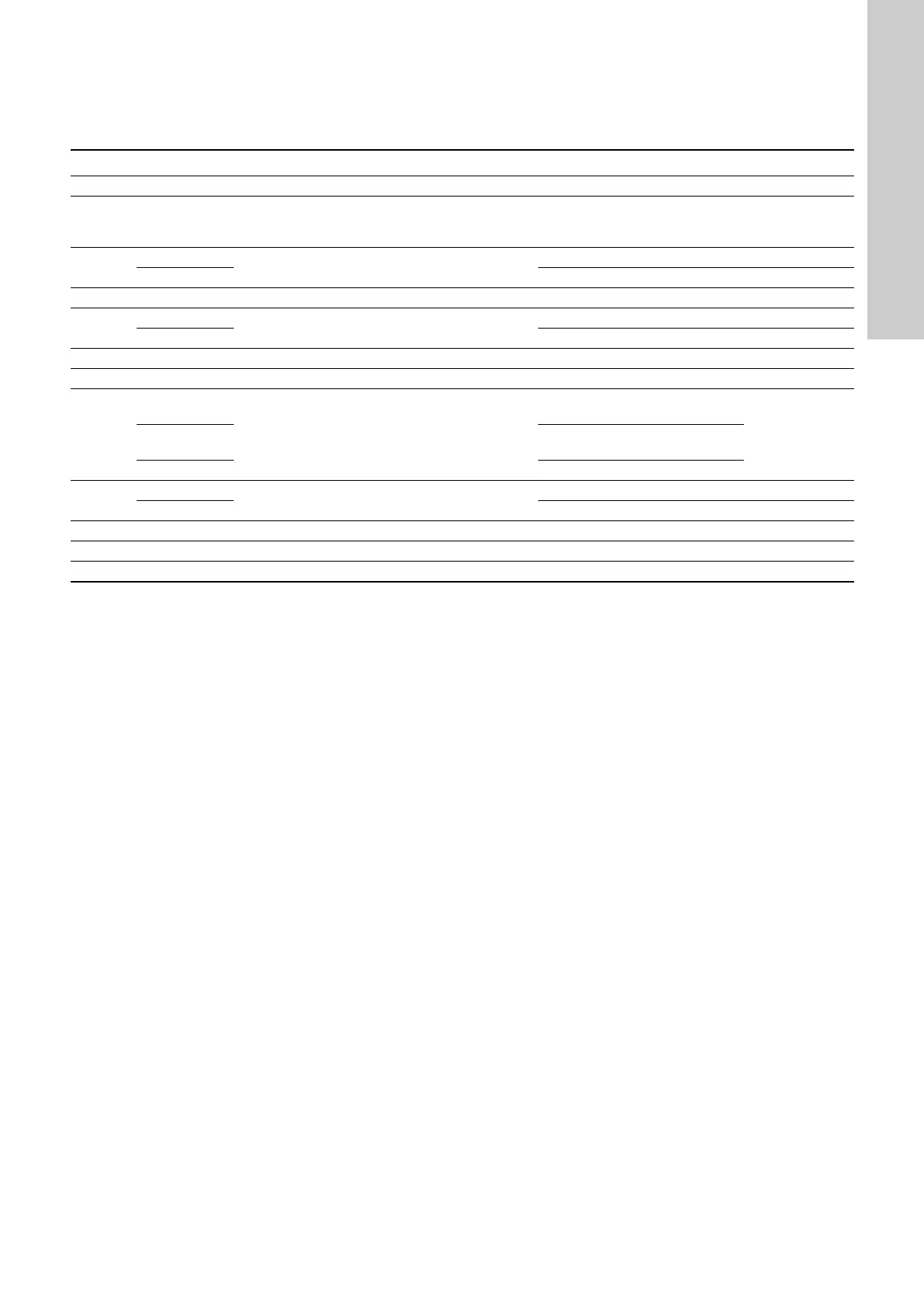

6. Torques and lubricants

This section shows the screws and nuts that must be tightened to

a certain torque and the lubricants to be used.

6.1 Special torques and lubricants

Cooling paste: Electrolube HTSP, 99239333 (1 kg)

Cooling paste: Corning 340, 00RM2502 (1 kg), as an alternative.

Grease: Rocol 22 (SAPPHIRE AGUA SIL), 96102356 (5 kg).

Soap: KEMA SSP-630 (Industrial spray), 98145099 (-).

Pos. Pump type Description Quantity Size Torque [Nm] Lubricant

92a All Screw (clamp) 1 M8 x 70 12 ± 2 -

155 All Intermediate flange 1 - -

Electrolube

HTSP or Corning

340

181

B

Union nut of cable 1

-50 ± 5 -

C and D - 75 ± 5 -

182 All Screw 4 M8 x 20 18 ± 2 -

183

B

Screw 1

M30 x 50 150 ± 10 -

C and D M24 x 40 200 ± 10 -

184 All Screw 6 M10 x 40 200 ± 10 -

186 All Screw 2 M6 x 10 7 ± 2/0 -

187

SE1 - originally

SC

Screw 4

M8 x 30 20 ± 2

-

SE1 - S-tube

®

M8 x 30 (with

low head)

15 ± 2

SEV M8 x 30 20 ± 2

188a

B

Screw 1

M10 x 25 50 ± 5 -

C and D M12 x 35 75 ± 5 -

190 All Nut, lifting bracket 2 - 50 ± 2 -

193 All Screw 2 M12 x 20 16 ± 2 -

- All O-rings All - - Rocol 22

Loading...

Loading...