English (GB)

11

9.2 Replacing the pin housing

9.2.1 Removing the pin housing

1. See section 9.1.1 Removing the cable.

2. See section 9.4.7 Removing the motor top.

3. Remove the earthing screw (173) including the washer

(173a).

4. Disconnect the wire pins from the pin housing (176).

5. Remove the plug protector (177), including the pin housing

(176).

6. Remove the pin housing (176) by pressing it up with the pin

pusher (D) below the pin housing.

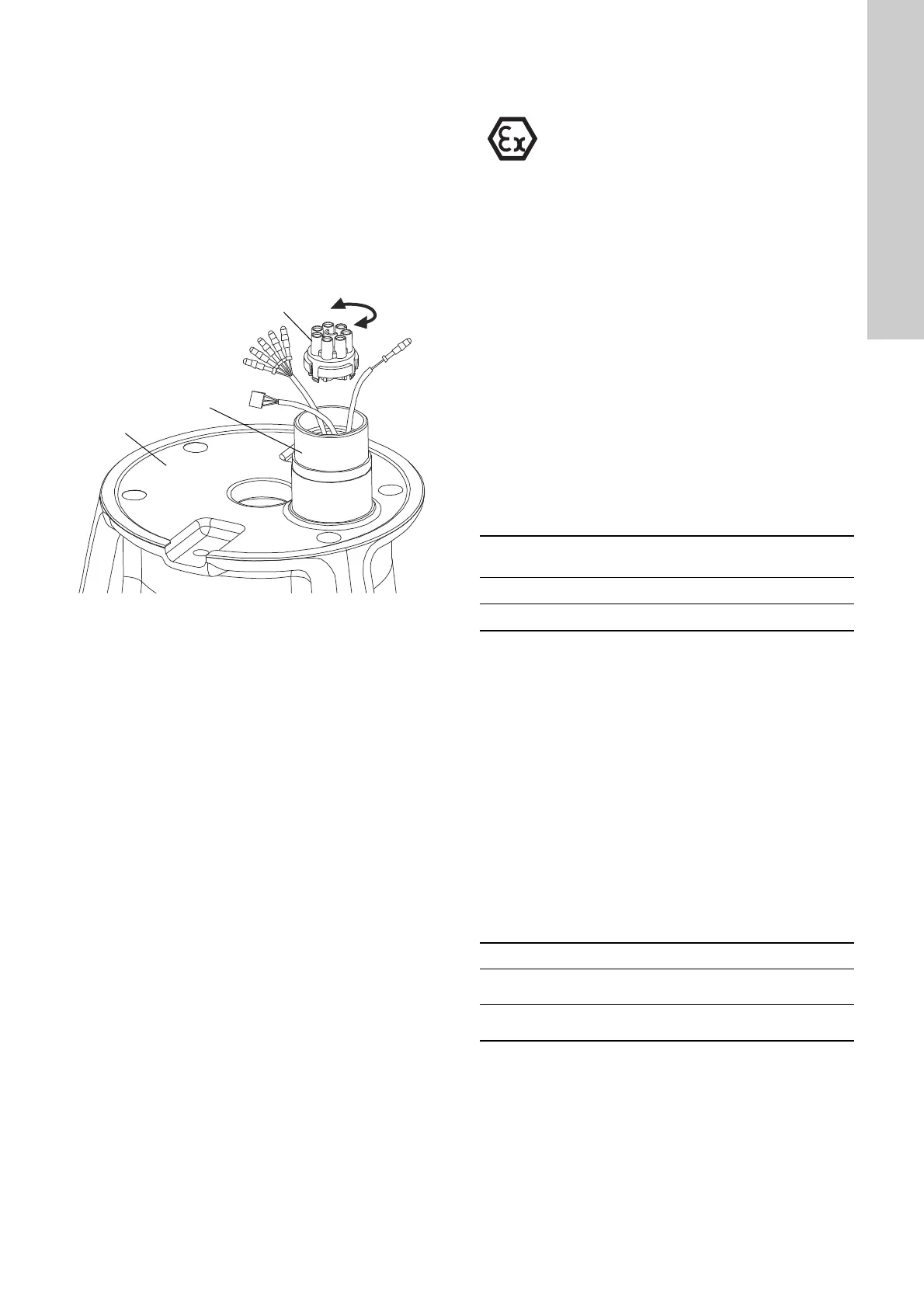

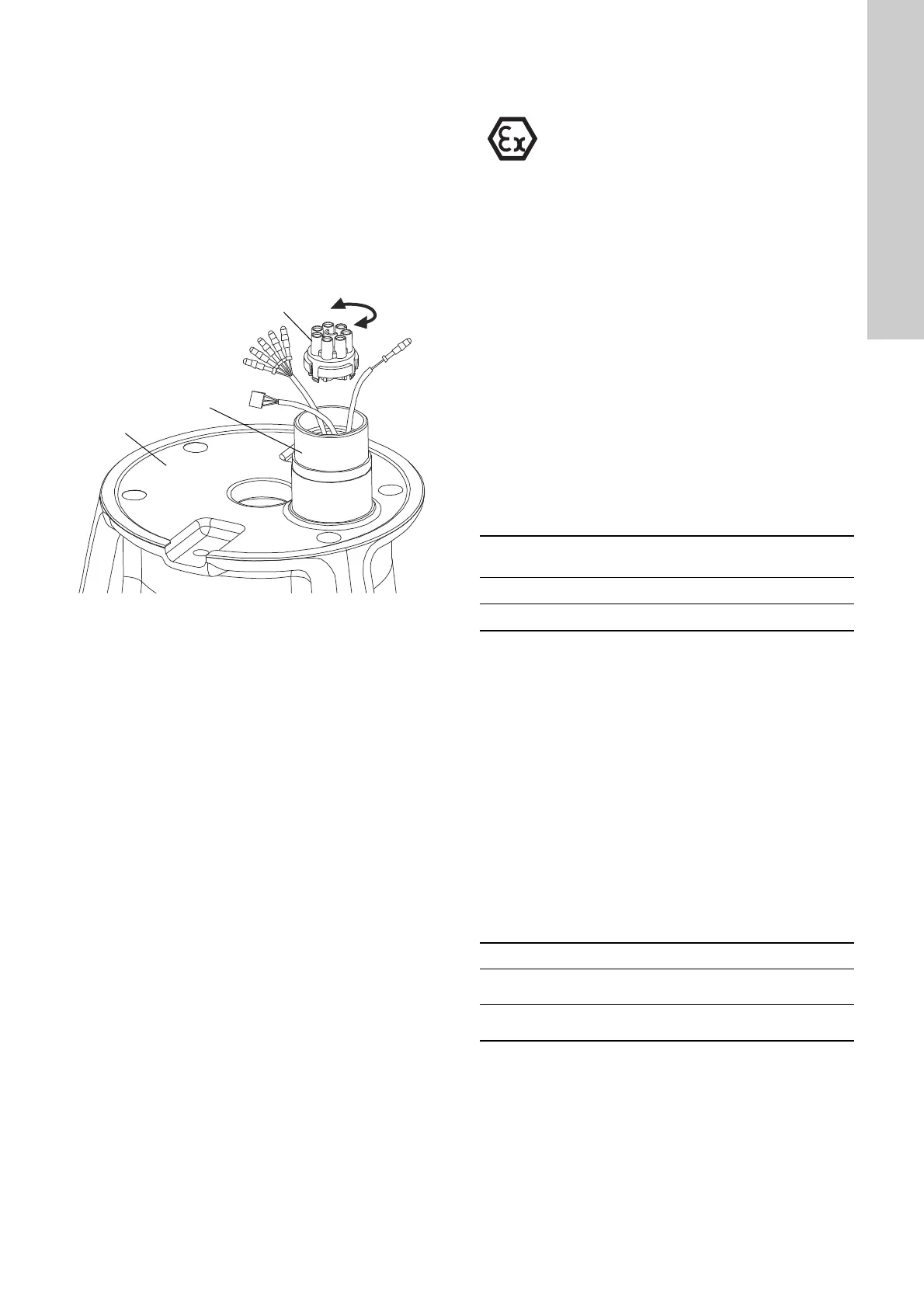

9.2.2 Fitting the pin housing

Fig. 7 Fitting the pin housing

1. Pull the wires (coming from the stator) gently through the plug

protector (177).

2. Fit the plug housing (177) to the stator housing (55).

3. Connect the wires (coming from the stator) to the pin housing

(176). See section 12.5.2 Wiring diagrams.

4. Fit the new pin housing (176) in the plug protector (177).

5. Connect the earthing screw (173) and washer (173a).

6. Assemble the pump according to the instructions in section

9.5 Assembling.

9.3 Replacing the protection sensors

For sensor positions, see section 12.4 Sensor positions.

All SE1 and SEV pumps have thermal protection incorporated in

the stator windings.

Pumps without sensor

Pumps without sensor have a thermal switch. Via the pump

controller safety circuit, the thermal switch will stop the pump by

breaking the circuit in case of high overtemperature

(approximately 150 °C). The thermal switch will reclose the circuit

after cooling.

The maximum operating current of the thermal switch is 0.5 A at

500 VAC and cos φ 0.6. The switch must be able to break a coil in

the supply circuit.

In the case of standard pumps, when closing the circuit after

cooling, the thermal switch can (restart the pump automatically

via the controller.

Pumps with sensor

Pumps with sensor have either a thermal switch and a Pt1000

sensor or a thermistor (PTC) in the windings, depending on the

installation site.

To find out whether the pump is fitted with a thermal switch or a

PTC thermistor, measure the motor winding resistance. See the

table below.

Via the pump controller safety circuit, the thermal switch or the

thermistor stops the pump by breaking the circuit in case of high

temperature, approximately 150 °C. The thermal switch or the

thermistor recloses the circuit after cooling.

The maximum operating current for both the Pt1000 and the

thermistor is 1 mA at 24 VDC.

Moisture switch and WIO sensor

The moisture switch is an NC switch (normally closed). In case of

moisture, the circuit is broken, and the current supply to the pump

is interrupted. If the moisture switch has been activated, it must

be replaced.

The WIO sensor measures the water content in the oil and

converts the value into an analog current signal. The two sensor

conductors are for power supply as well as for carrying the signal

to the IO 113 module. The sensor measures the water content

from 0 to 20 %. It also sends a signal if the water content is

outside the normal range (warning), or if there is air in the oil

chamber (alarm).

TM06 9234 2017

The protection sensors must be replaced by

Grundfos or an Ex-approved service centre.

Without

cable

With 10 m

cable

With 15 m

cable

Thermal switch < 50 mΩ < 320 mΩ < 390 mΩ

PTC thermistor > 100 mΩ > 370 mΩ > 440 mΩ

Fault indication Reaction

Water in oil

Warning.

The pump keeps running.

Sensor not covered by oil

Alarm.

The pump stops.

Loading...

Loading...