English (GB)

12

9.3.1 Replacing the thermal switch, Pt1000 or thermistor

(PTC)

In case the thermal switch, Pt1000 or thermistor (PTC) is not

operating, even if the pump has cooled down, the stator has been

damaged by too high temperature.

The thermal switch, Pt1000 or thermistor (PTC) is built into the

stator windings and cannot be changed without replacing the

stator. See section 9.4 Dismantling.

9.3.2 Replacing the water-in-oil sensor (WIO)

Removing the WIO sensor

1. Dismantle the pump according the instructions in section

9.4 Dismantling.

2. Cut off the cable shoe of the WIO sensor (521).

3. Remove the cable sleeve from the wire, and pull the sensor

cable out of the intermediate flange (155).

4. Remove the rubber bush and the disk springs from the wire.

Fitting a new WIO sensor

1. Fit the four spring washers and the rubber seal on the sensor

cable. For correct positioning, see fig. 8.

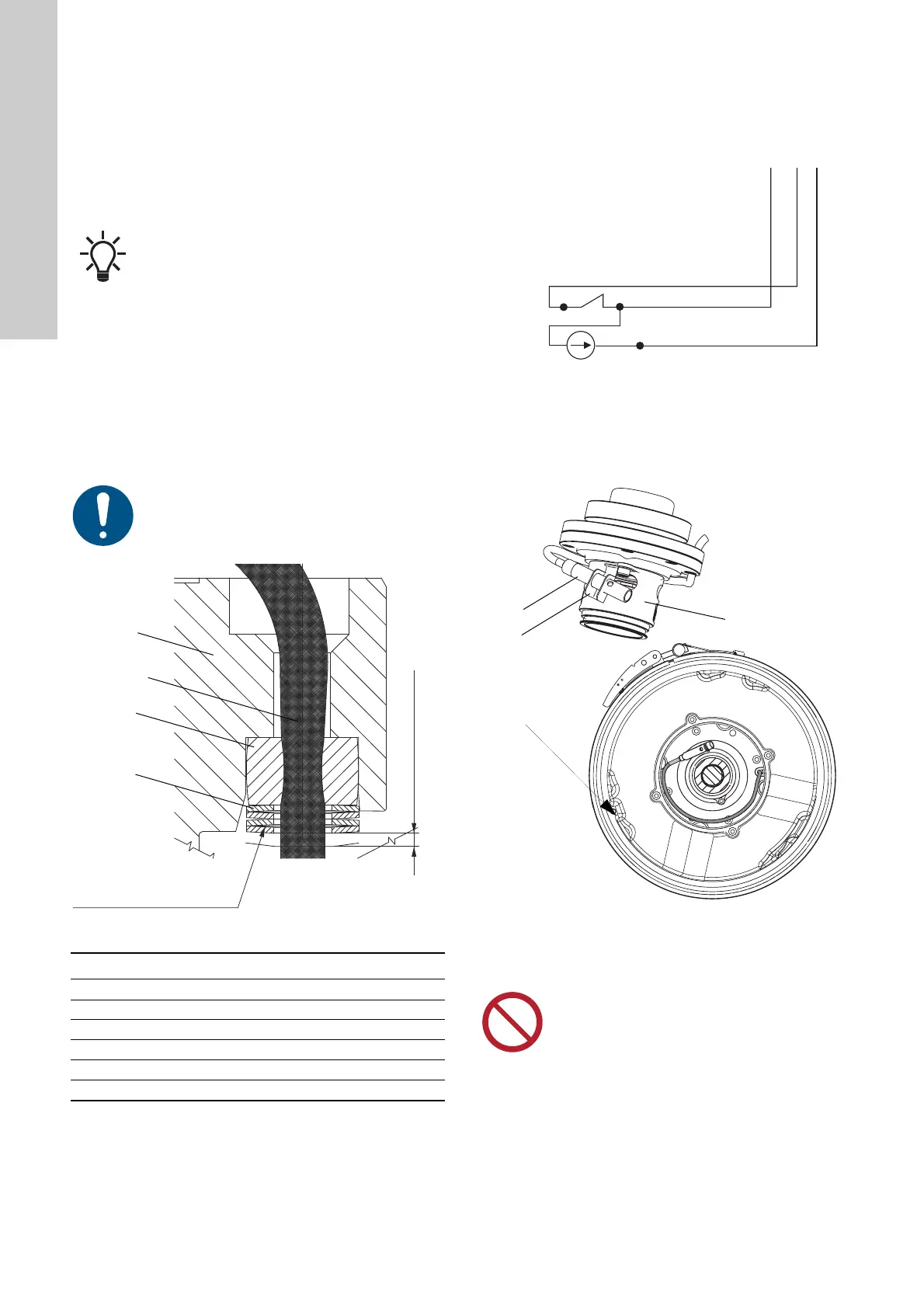

Fig. 8 Position of spring washers

2. Pull the sensor cable up through the intermediate flange

(155).

3. Push the protection sleeve on the sensor cable.

4. Cut the cable to a suitable length and connect the wires

according to the wiring diagram. See section 12.5 Electrical

data.

Fig. 9 Wiring diagram for WIO sensor

5. Fit the sensor (521) in the bracket (522).

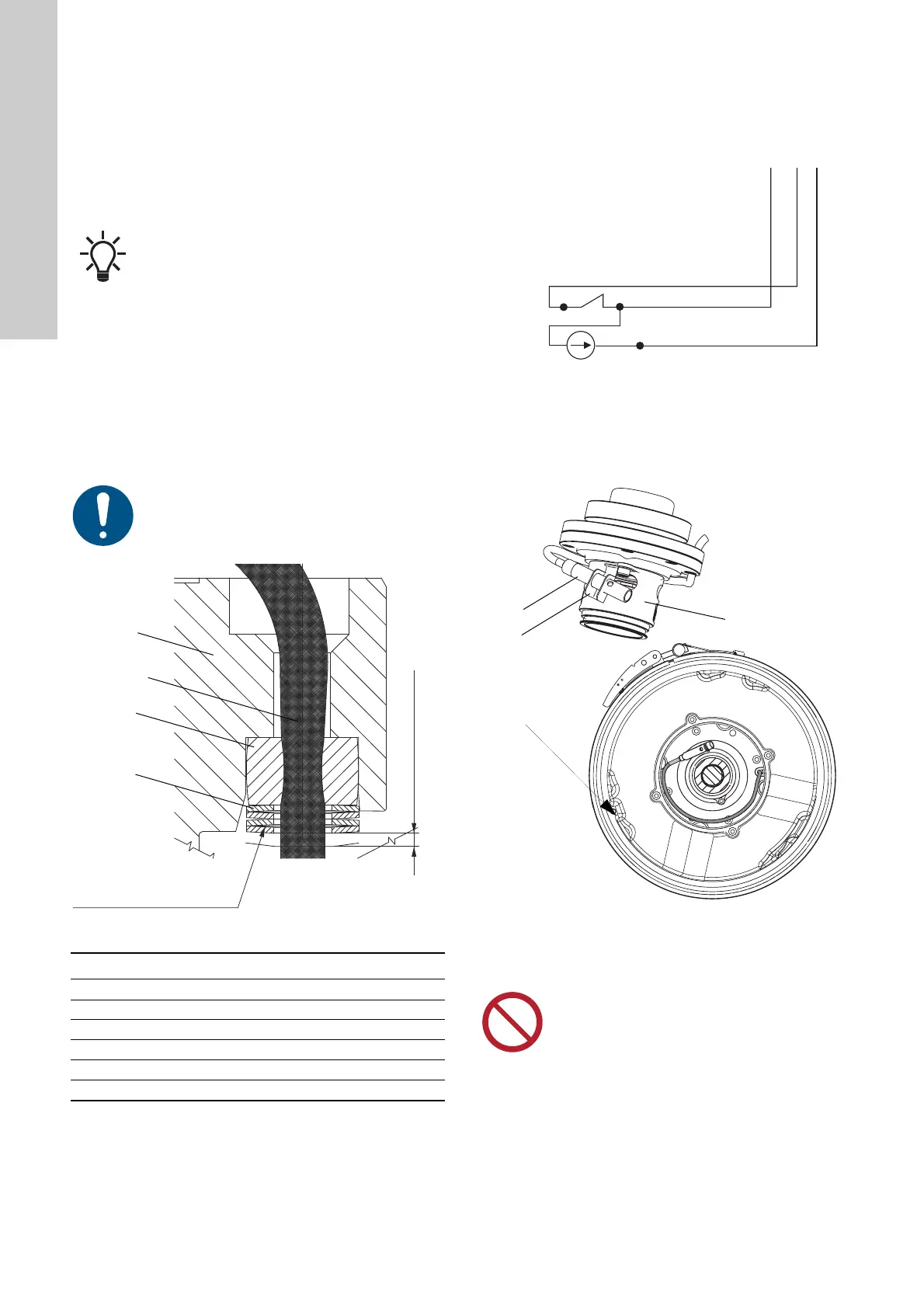

6. Fit the sensor with screw (186) so that the sensor is

positioned in the direction of rotation and approximately 55 °

clockwise after the rotation stop (6a). See fig. 10.

Fig. 10 Fitting the water-in-oil sensor

7. Assemble the pump. See section 9.5 Assembling.

9.3.3 Replacing the moisture switch

The moisture switch must be stored in air-tight packaging to

protect the expansion part against moisture. The relay is factory-

set to 5 mm and requires no further setting.

We recommend that you change the motor oil in case

the WIO sensor is changed.

The spring washers and rubber seal must always be

replaced if removed.

TM06 9202 1917

Pos. Description

1 Sensor cable

2 Rubber seal

3 Spring washer

4 Spring washer stack

155 Intermediate flange

X Minimum compression is 1.4 mm

TM03 2660 4705TM03 3668 0606 - TM03 1561 0606

Do not touch the head of the moisture switch with wet

or oily hands. Moisture in the sensor head before

installation causes false measuring values.

Moisture switch

Brown

WIO

White

Brown

Blue

Black

Loading...

Loading...