37

ACTIVATION METHODS (GENERAL)

Setpoint activation for Fill, Batch, Discharge, and Both can be initiated in one of two ways: Tare or

Auto. Check-weigh operations have no start function. Independent setpoint operations are limited

to Above or Below activation. The Model 370 and Model 375 setpoint option board may be

connected in-series with a larger automated control system or a manually activated switching

device. A foot switch, a two-hand safety station, or other permissive-start devices may be used

for safety or system compatibility.

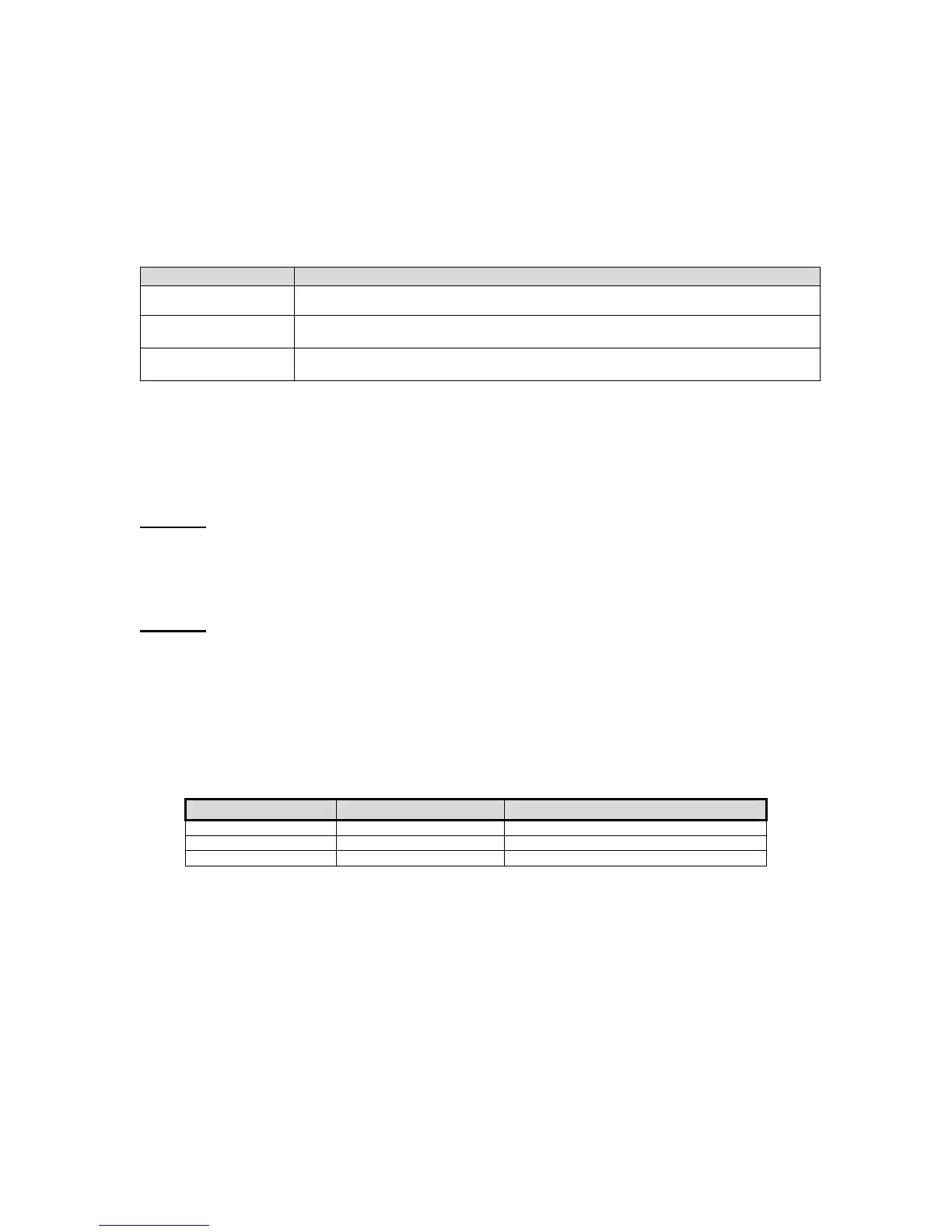

Activation Method Description

Tare Operation [TARE] activates the setpoint. It waits for a no-motion condition, then tares scale to net zero.

The appropriate setpoint is then activated.

Remote Key

The [REMOTE KEY] closure does not exist on the Model 370/375. Do not use

this choice.

Auto-Start

Automatically activates the setpoint. It waits for a no-motion condition, then adds

the target to the current displayed weight to achieve a relative cutoff value.

Pre-Acts (General)

Pre-Acts are control actions prior to reaching a desired target value. Necessary to prevent over-

filling due to product flow rate, relay and valve response time and product suspension, Pre-Acts

and other system variables affect how much more product reaches the weighing device after the

Model 370/375 has deactivated a setpoint.

Pre-act 1

Used in dual-speed applications, pre-act 1 specifies when the 370/375 should switch from fast-fill

to slow-fill, allowing the system to perform the bulk of a filling operation as quickly as possible

before switching to a more manageable dribble mode for final cutoff. When using a single-speed

device, set pre-act 1 to 0.

Pre-act 2

Specifies the weight where the final cutoff should occur, enabling the 370/375 to compensate for

a dispensing control's closure time and account for free-fall material. Free-fall is the amount of

product that has passed the point of the dispensing control yet not yet reached the weighing

device.

Pre-act values are entered in terms of the amount of product that would over-fill or 'how early' to

close the control device. For instance, after repeated tests, a system consistently over-fills by .5

lbs. This is the value that should be entered as the pre-act. The 370/375 would then deactivate

the setpoint .5 lbs. less than the desired final target value.

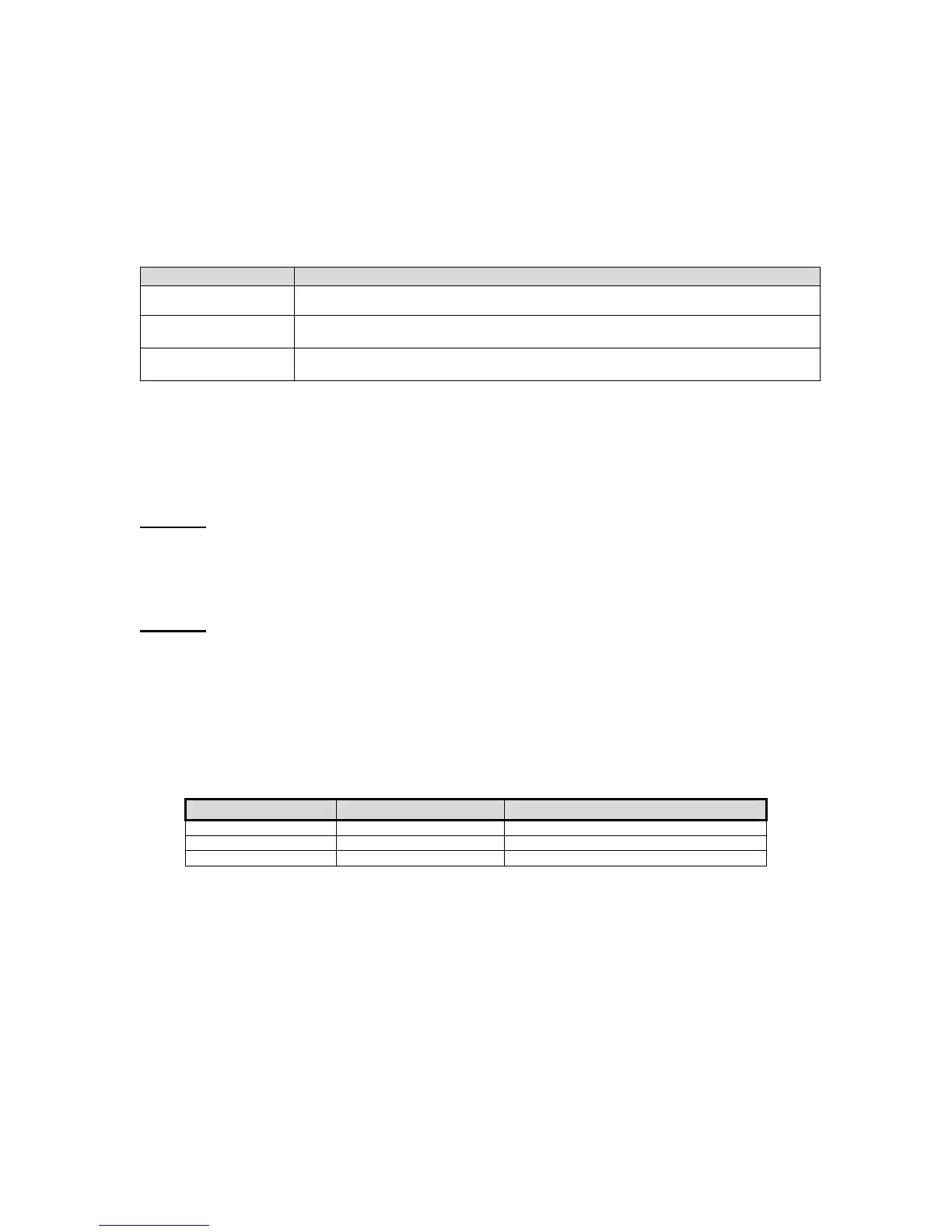

Parameter Setting Actual Cutoff Value Comments

Target = 400 lbs. Desired final weight.

Pre-Act 1 = 28 400 – 28 = 372 Switch to slow feed at 372 lbs.

Pre-Act 2 = .5 400 – 0.5 = 399.5 Final fill valve closes at 399.5 lbs.

Learn Feature (General)

The Model 370/375 can 'learn' optimal pre-act values. When enabled, the learn feature will

automatically adjust the final cutoff value based on an analysis of the five previous fills, helping

achieve a final target by compensating for product viscosity, changes in plant air pressures, sticky

valves, etc. For each cycle, the prior five final weights are analyzed and a new pre-act value is

calculated.

Pause Feature (General)

The Model 370/375 can pause setpoint operations. This is useful as a safety device, for mid-cycle

operator breaks, mechanical adjustments, etc.

Loading...

Loading...