19

E

N

G

L

I

S

H

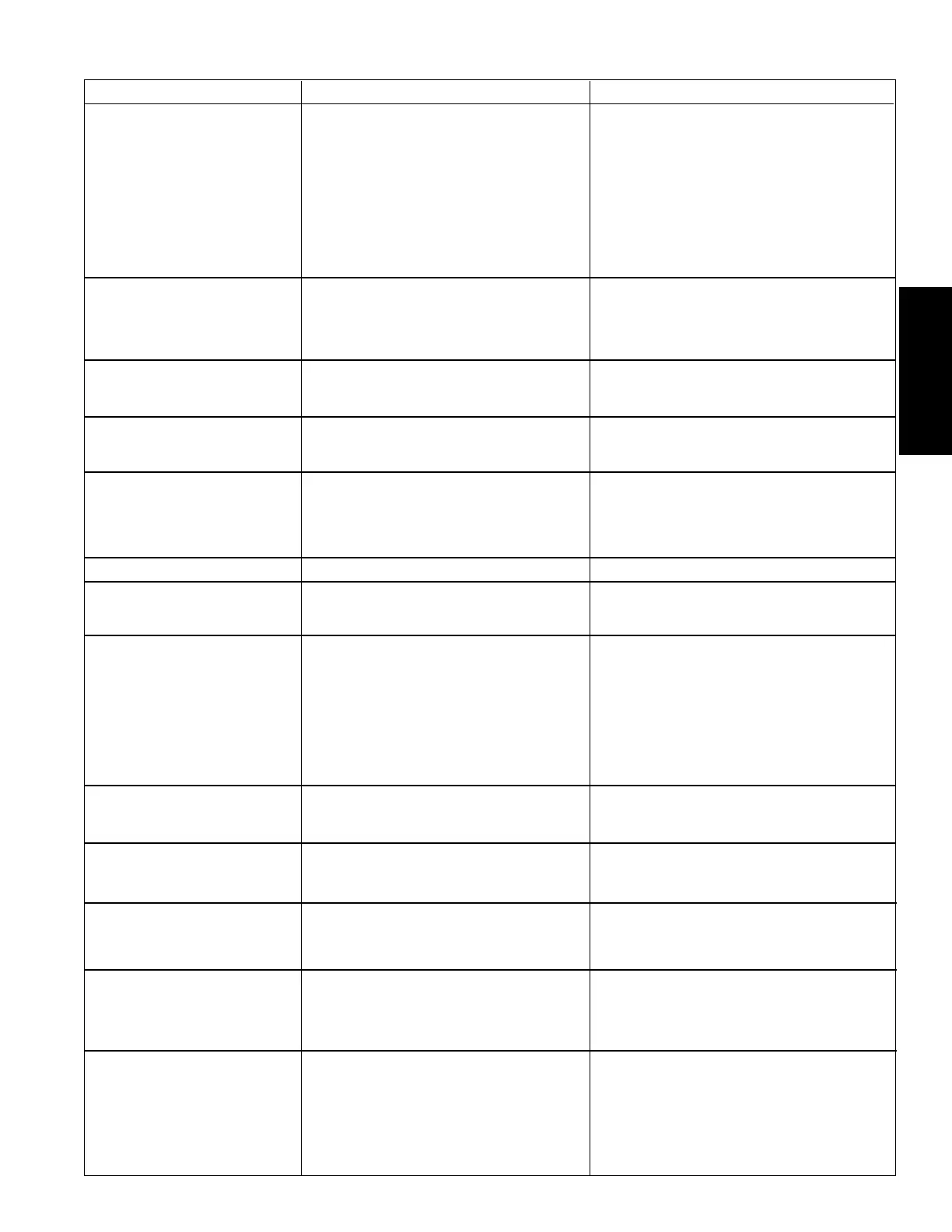

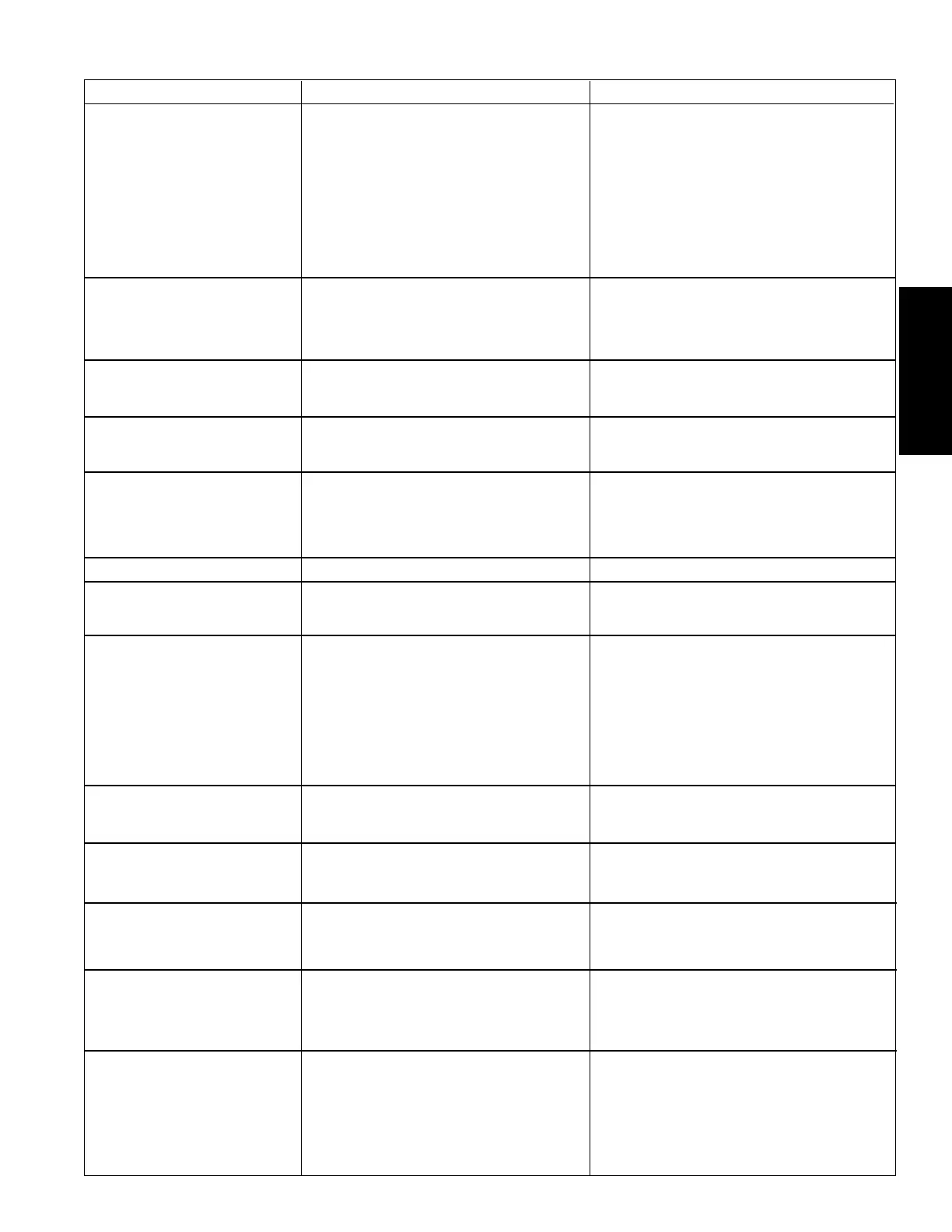

TROUBLE SHOOTING GUIDE

SYMPTOM / FAULT POSSIBLE CAUSES CORRECTIVE ACTION

1. Unloader solenoid stuck. Repair.

2. Unloader solenoid coil defective. Replace.

3. Hot gas by-pass valve set too high or sticking. Reset or repair.

4. Faulty low pressure transducer. Check pressure reading. Calibrate/replace.

(Consult factory for calibration).

1. Unloader solenoid stuck open. Reset or repair.

2. Faulty low pressure transducer. Check pressure reading. Calibrate/replace.

(Consult factory for calibration).

1. Excessive fluctuation in suction pressure. Check hot gas valve set point.

2. System load fluctuating. Stabilize load.

3. Hot gas valve set too high. Return valve to factory set point.

1. Low suction pressure. Reset hot gas valve to factory set point.

2. Defective or improperly set expansion valve.

Reset to 3-6°F/1.7-3.3°C superheat.

3. Defective or improperly set liquid injection Reset to 65°F/18.3°C return gas temperature

valve. at no load.

4. Suction line filter restricted. Check for pressure drop across filter/replace elements.

1. See: Cold compressor

1. Oil return screen clogged Clean.

2. Freon leak Repair leak.

3. See: Cold compressor

1. Desuperheating valve is out of adjustment Check operation and adjust.

2. Liquid line filter clogged Check/replace.

3. Discharge temperature of 275°F/135°C Check unit application.

4. Compressor internal valves worn or Replace.

damaged

5. Defective liquid injection valve. Replace.

6. Compressor not unloading properly. (20 HP Unloader mechanism. Check/replace.

and up)

7. Refrigeration system leak Leak check/repair and recharge system.

1. Unit overload Check inlet air temperature, must be below

120°F/49°C.

2. Defective Temperature sensor. (TT1) Check/Replace.

1. Low suction pressure Reset hot gas valve to factory setting.

2. Incorrect superheat setting on TXV Rest to 3-6°F/1.7-3.3°C superheat.

3. Defective temperature sensor. (TT2) Check/Replace.

1. Incorrect setting on drain valve. Increase drain open time or decrease time

between opening.

2. Drain valve not operating properly. Repair or replace.

3. Float switch defective Check/Replace.

1. See "HIGH REFRIG PRESS"

water-cooled units

1. Dirty separator element cartridges Replace separator cartridges. See section

4.0 in Manual.

2. Unit overload Check inlet flow, pressure, and temperature and

verify if within design conditions.

3. Inlet and/or outlet pressure transducers Replace and/or calibrate. For calibration

(PT1 and PT2) defective/out of calibration. consult factory.

4. Defective CPU or component module. Check/Replace.

System Noise

Compressor will not unload

Compressor will not load

Rapid Unloader Cycling

Cold Compressor

(Cylinders and Crankcase

Sweating

Compressor Flooding

Low Crankcase Oil Level

High Crankcase Tempera-

ture (should be 100°F/38°C

to 130°F/55°C)

High inlet air temperature to

unit "HI INLET AIR TEMP"

(optional)

Low air temperature in

evaporator "LOW EVAP AIR

TEMP" (optional)

High condensate level in

drains "DRAIN # HI LEVEL"

(optional)

Low water pressure enter-

ing condenser (water-

cooled units) "LOW WATER

PRESS" (optional)

High pressure drop across

dryer air side

"CHECK SEPARATOR"

(optional)

1. Unit foundation improperly isolated. Isolate foundation.

2. Improper support or isolation of piping. Use correct piping techniques, and

support piping with suitable hangers.

3. Slugging due to refrigerant feed back. Check expansion valve setting; check

sensor bulb for looseness and correct location.

4. Piping vibration. Support pipes as required, check piping

connections.

5. Hissing (insufficient refrigerant flow through Reclaim refrigerant, replace strainer, and recharge

expansion valve or clogged liquid line strainer). with the proper amount of refrigerant.

6. Hot gas by-pass valve chattering. The chattering noise is normal and

does not affect the operation of the unit.

Loading...

Loading...