2

R649c

SEPTEMBER 2018

MATERIAL SPECIFICATIONS

Mechanical

Maximum Safe Working Pressure:

400 psig (28 bar) flanged, 800 psig (55 bar) welded

Maximum Opening Pressure Differential:

400 psig (28 bar) flanged, 800 psi (55 bar) all sizes

Ambient Operating Temperature:

-40˚F to 122˚F (-40˚C to 50˚C)

Refrigerant Operating Temperature:

-75˚F to 240˚F (-60˚C to 115˚C)

IP67 Rating (NEMA 6)

Electrical:

Supply Voltage: 24VAC or 24VDC via NEC Class 2 Source

Power Draw: 20W per valve

Input Control Signal Types: 4-20mA, 0-20mA, 0-5VDC,

0-10VDC, 1-6VDC, relay closed contact

Output Feedback Signal Types: 0-20mA, 4-20mA

Material Specifications

Body: Ductile iron, ASTM A536

Bonnet Plate: Steel, zinc plated with yellow chromate

V-port Seal: Teflon

Cartridge Assembly: Stainless Steel

Cartridge O-ring: Neoprene

Actuator Housing: Aluminum

Corrosion Protection: Zinc plating is standard on

bodies up to 1-1/4”, ACT™ available on all valves

APPLICATIONS

The Hansen Motorized Control Valve is ideal for applications

where external leakage is intolerable. The valve is suitable

for use with a variety of fluids, including those that are

incompatible with copper, such as ammonia, because the

motor is isolated from the refrigerant. Typical uses include

slow opening solenoid valve, temperature controlled

evaporator regulator, liquid injection to screw compressors,

pressure control, liquid level control of pump accumulators,

high side receivers or low side flooded chillers, or as a

gravity drain valve.

The full ported MCV valve series is for computer controlled

operations using 4-20 mA signals. The MCV is ideal for

precise temperature and pressure control, hot gas defrost,

and other applications where accurate process control is

required. The MCV valves series is also for applications

requiring open/close operation only.

The MCR valve with expansion plug is for high pressure

drop applications such as liquid makeup and liquid

injection. The MCR valve series is also suitable for suction

line, liquid line and hot gas line where reduced capacities

more closely match the expected operating conditions.

The MCXV valve series is best suited for liquid injection

of screw compressors and direct expansion evaporators.

Refer to pages 3-5 for typical applications.

ADVANTAGES

The Motorized Control Valve can be used for applications

which require a very low pressure drop (e.g. suction lines),

or no pressure drop (e.g. equalizing or drain lines). No

pressure drop is required to operate, unlike most pressure

regulators and solenoid valves which require a minimum

2 psi pressure drop to keep the valve fully open.

Motorized Control Valves are drop-in replacement for

Hansen and other select solenoid and pressure regulating

valves.

The Motorized Control Valve does not require stem shaft

heaters like other open motorized valves.

The Motorized Control Valve is slow opening and closing

(ranging from 13 to 45 seconds) depending on valve size

and speed settings which minimizes the potential for liquid

velocity shock or “water hammer” often experienced with

quick opening and closing solenoid valves.

POWER BACKUP FEATURE

The Motorized Control Valve is available with an optional

power backup system that will control the valve to a user

defined location upon a loss of the incoming voltage. This

system can be used in place of an upstream solenoid to the

valve. Refer to pages 25 – 26 for details and wiring.

VALVE SIZING

Proper valve sizing is important for smooth operation and

long, trouble-free life of the valve. Therefore, capacity

at both the maximum and minimum flow and pressure

drop should be analyzed. Pressure drop across the valve

dramatically increases the capacity of the valve. A valve with

8 psi pressure drop has twice the capacity of a valve with a

2 psi pressure drop. Ideally, valves should operate between

15% and 85% open for optimum trouble-free control. Refer

to the capacity tables on pages 8–16 or the Hansen sizing

program found at www.hantech.com.

LIQUID MAKE-UP APPLICATIONS

For applications with a large pressure drop across

the Motorized Control Valve, attention must be paid to

proper outlet line sizing to accommodate flash gas. It is

recommended that dual Motorized Control Valves in parallel

be used when the low load (weekend load) is less than 15%

of the properly sized full load capacity for the application.

Also, for applications requiring a valve size over 2˝ port size,

it is strongly recommended that two liquid make-up valves

in parallel be used. This valve arrangement could be two

Motorized Control Valves or one solenoid valve with hand

expansion valve and one Motorized Control Valve to be used

as a “trim” valve under low load conditions.

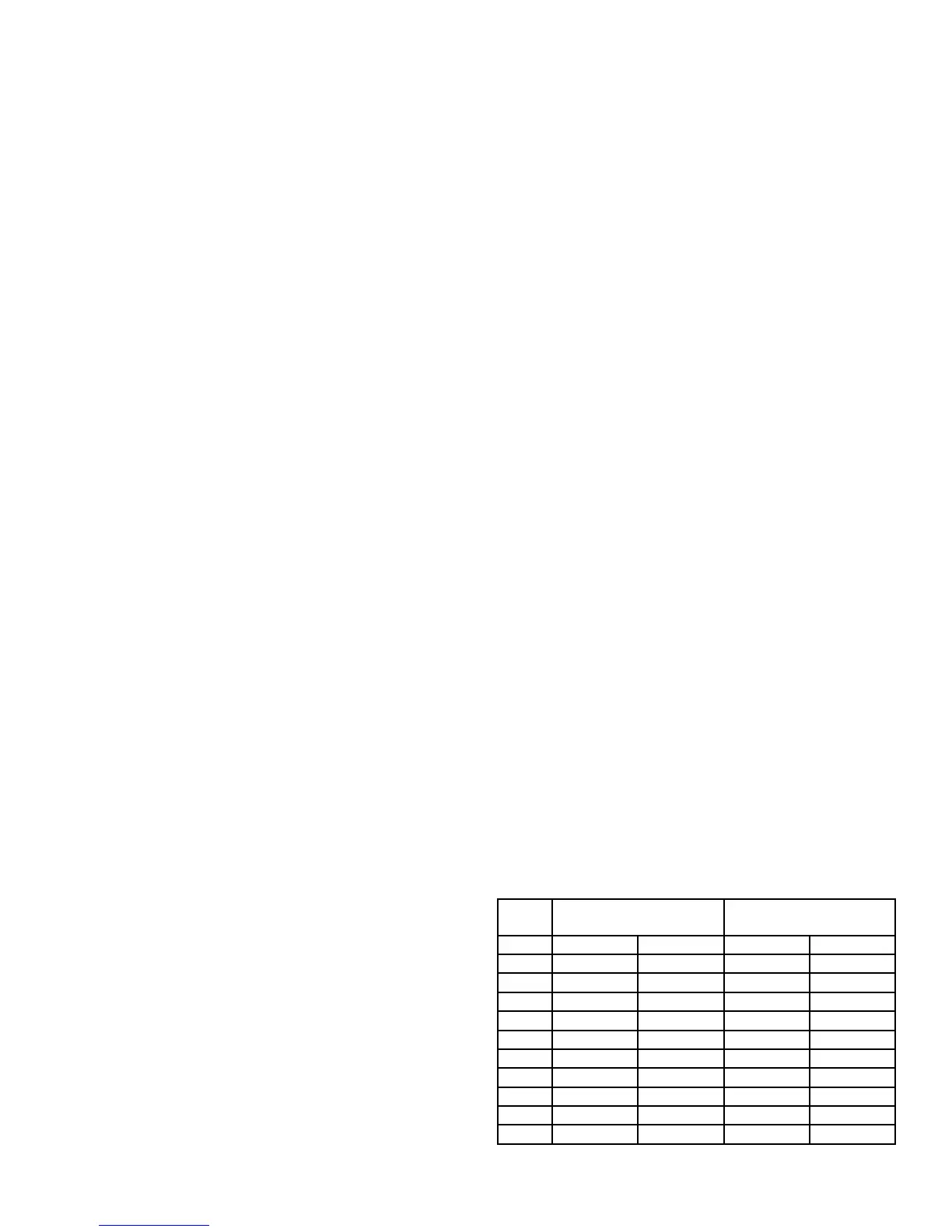

LIQUID LINE SIZING

Liquid lines should be adequately sized for the capacity

of the valve. Listed below are the IIAR recommended

capacities for liquid lines. R22 capacities based on 3 ft/s

liquid velocity. For R134a, use 94% of R22 capacity; R404

80%; R507 60%.

TABLE 1

LINE

SIZE

MAXIMUM CAPACITY

AMMONIA

MAXIMUM CAPACITY

R22

1/2˝ 32 Tons 112 kW 8 Tons 27 kW

3/4˝ 58 Tons 208 kW 14 Tons 49 kW

1˝ 97 Tons 340 kW 24 Tons 82 kW

1-1/4˝ 179 Tons 625 kW 42 Tons 147 kW

1-1/2˝ 254 Tons 890 kW 58 Tons 202 kW

2˝ 496 Tons 1740 kW 110 Tons 384 kW

2-1/2 ˝ 729 Tons 2550 kW 155 Tons 543 kW

3˝ 1160 Tons 4060 kW 241 Tons 845 kW

4˝ 2040 Tons 7140 kW 416 Tons 1457 kW

5˝ 3300 Tons 11606 kW 654 Tons 2289 kW

6˝ 4890 Tons 17198 kW 946 Tons 3309 kW

NH3 capacities are based on IIAR Refrigeration Piping

Handbook tables.

Loading...

Loading...