41

R649c

SEPTEMBER 2018

SERVICE AND MAINTENANCE

MCV DISASSEMBLY

1. Isolate the valve from the refrigerant pressure and

evacuate the refrigerant.

NOTE: Always use caution when removing the actuator

and entering the valve cavity.

2. Disconnect the red and green cables from the actuator.

3. Remove the actuator by loosening but not removing

the set screws.

4. To enter the valve cavity, carefully loosen and remove

the larger bonnet bolts and then the bonnet.

5. Grasp the top of the cartridge and while lifting out

squarely, remove the cartridge assembly, taking

care not to bend the shaft. If cartridge removal is

difficult, remove by placing the MCT on the cartridge

and rotating counterclockwise and the cartridge will

press out. WARNING: Don’t bend shaft.

6. Remove the V-port from the cartridge assembly by

unscrewing the rotor counterclockwise.

MCV ASSEMBLY

1. Install new cartridge gasket to counter bore on top

face of valve.

2. Ensure V-port is installed into new rotor cartridge.

To install V-port into cartridge fully supporting the

V-port and cartridge while carefully aligning the

threaded shaft of cartridge with the low friction nut

of V-port. Carefully thread together 6-8 turns, and

align the anti-rotation slot on the V-port with the

anti-rotation pin of the cartridge. Fully thread the

V-port into the cartridge, screwing the V-port fully

into the cartridge by turning the rotor clockwise.

3. Install new rotor cartridge/V-port assembly into valve.

4. Install new bonnet over cartridge assembly and

torque bolts to 35 ft-lbs.

5. Install O-ring onto cartridge.

6. Place Manual Control Tool (MCT) onto the top of

magnetic cartridge assembly. Continue to rotate

the tool counterclockwise until the valve is closed

and the V-port will no longer move.

7. Grease exterior of cartridge above the O-ring with

supplied low temp, high load, low RPM grease such

as Mobilith SHC PM 460 or similar.

8. Check the base of the actuator to ensure that the set

screws are not protruding past the ID of the threaded

ring. If necessary back the set screws out to prevent

interference during installation.

9. Install new actuator onto cartridge. Press firmly down

on the top of the actuator to ensure it fully seats. The

gap between the base of the actuator and bonnet

should be less than 1/16”.

10. Rotate actuator to orient in desire position and torque

the 3 set screws at base to 4 in-lb using 3/32” hex

key.

11. Connect the red and green cables to the actuator.

12. Upon power-up, the valve will automatically calibrate.

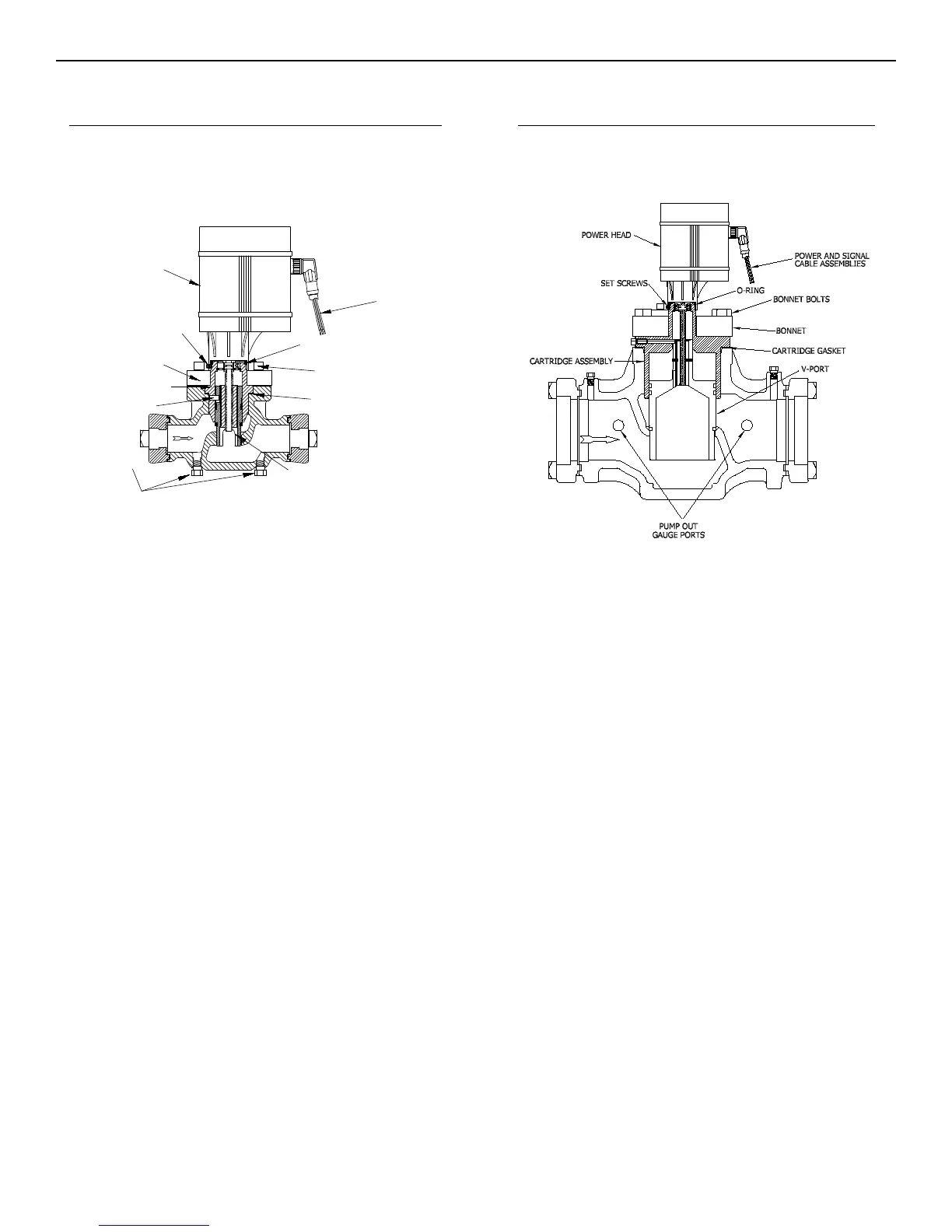

POWER AND SIGNAL

CABLE ASSEMBLIES

O-RING

BONNET BOLTS

BONNET

GUIDE PIN

CARTRIDGE GASKET

V-PORT

PUMP OUT

GAUGE PORTS

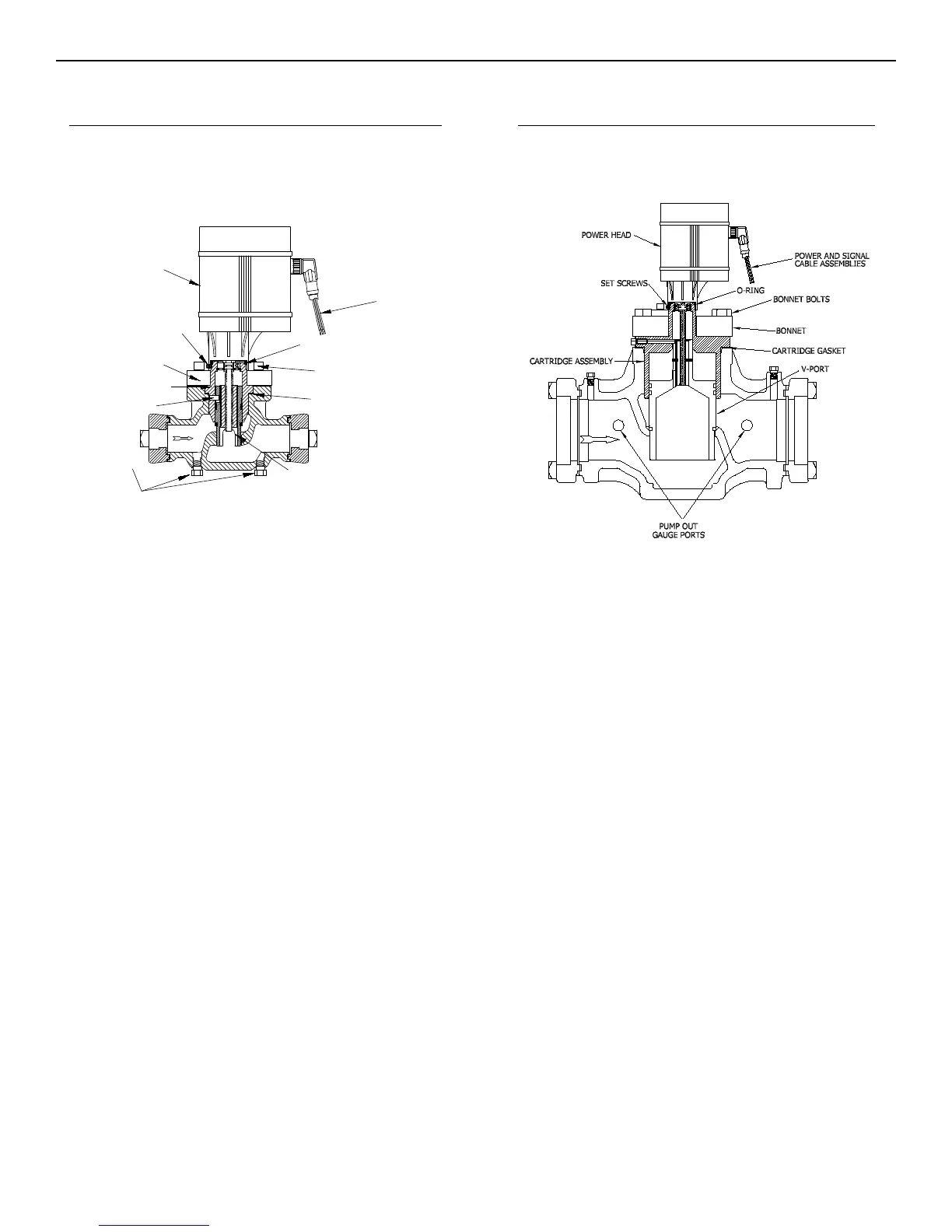

ACTUATOR

SET SCREWS

CARTRIDGE ASSEMBLY

FIGURE 31

3/4” THRU 2” MOTORIZED CONTROL VALVE 3” THRU 4” MOTORIZED CONTROL VALVE

FIGURE 32

Loading...

Loading...