42

R649c

SEPTEMBER 2018

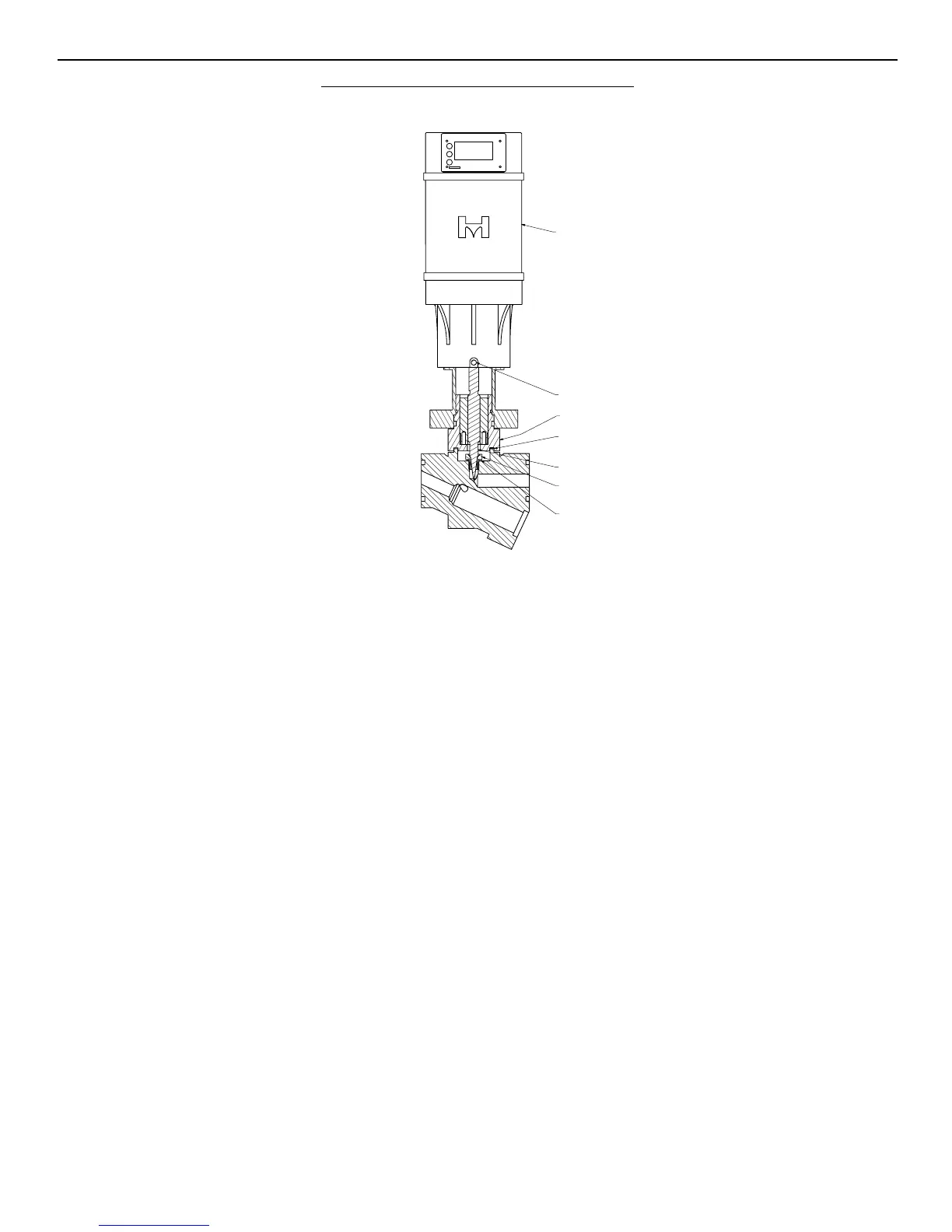

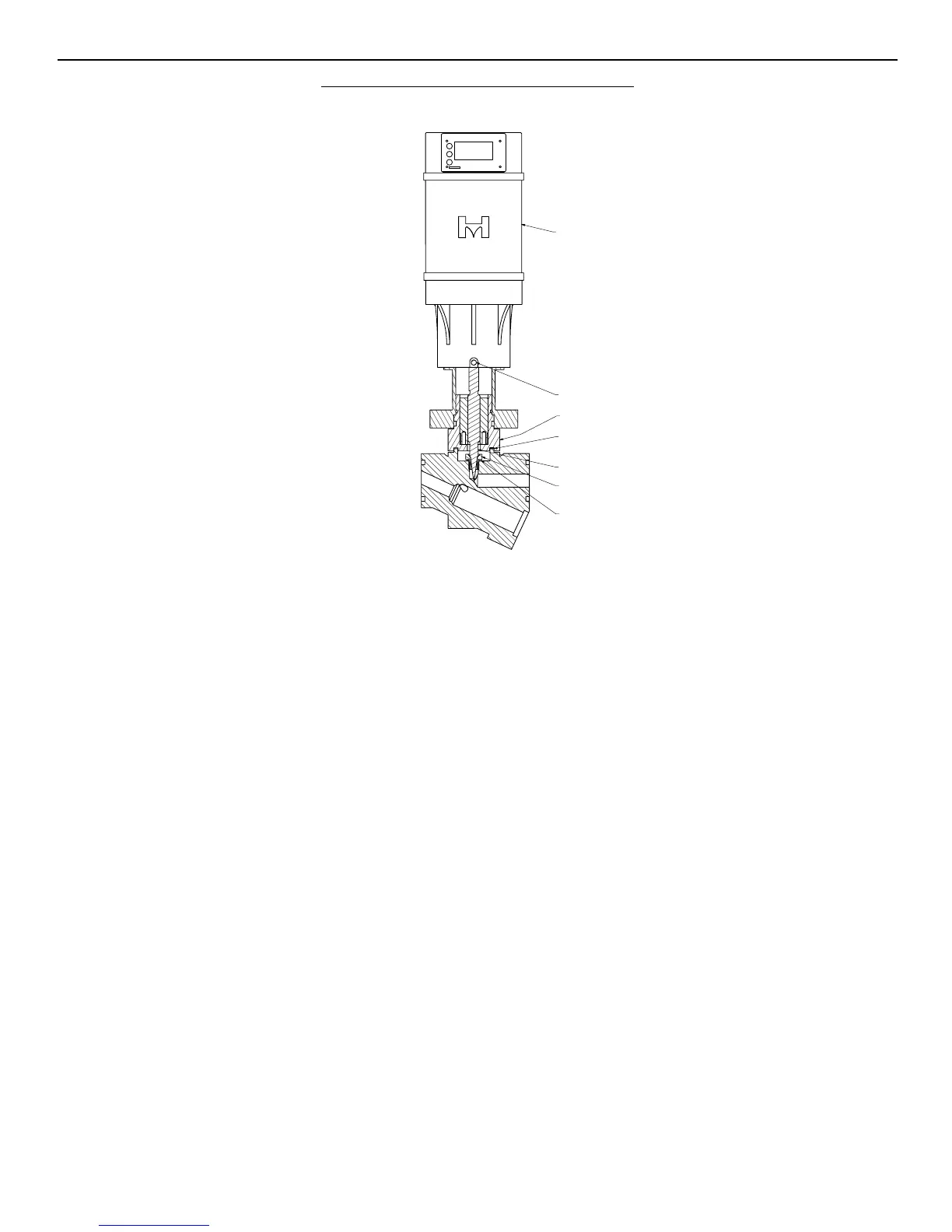

MCXV DISASSEMBLY

1. Isolate the valve from the refrigerant pressure and

evacuate the refrigerant.

NOTE: Always use caution when removing the cartridge

and entering the valve cavity.

2. Disconnect the red and green cables from the actuator.

3. Loosen but do not remove the set screws and lift the

actuator off the cartridge.

4. To enter the valve capacity, carefully loosen and

remove the larger bonnet bolts from bottom of valve

and then the bonnet.

5. Grasp the top of the cartridge and remove the

cartridge assembly by lifting it out squarely taking

care not to bend the shaft. If the cartridge removal

is difficult, remove it by placing the MCT on the

cartridge and rotating counterclockwise and the

cartridge will press out. CAUTION: Do not bend shaft.

6. Using a 7/16 inch socket or wrench remove the seat

(P/N 75-3118) and washer (P/N 75-3119)

7. Rotate needle clockwise and remove. This is the lowest

level disassembly intended for the operator to complete

MCXV ASSEMBLY

1. Install new seat washer (P/N 75-3119) onto seat (P/N

75-3118) and apply refrigerant suitable thread locker

to seat threads

2. Install assembled seat into body and torque to 5

ft.-lbs.

3. Thread modulating needle into cartridge assembly

counterclockwise (This is a left hand thread).

4. Using MCT, rotate the magnet while threading the

modulating needle into the cartridge and ensure the

needle engages the drive mechanism.

NOTE: If the needle bottoms out (protrudes more than ½”),

the needle is not engaged into the drive mechanism.

If this happens loosen the needle slightly and rotate

the magnet a fraction of a turn until the needle is

able to be properly threaded into the cartridge.

5. Lubricate gasket with refrigeration oil and install

onto the body ensuring it lies concentric with the

raised surface

6. Install cartridge assembly onto body

7. Install O-ring onto cartridge

8. Place MCT onto the top of the cartridge assembly

and rotate counterclockwise until the valve is closed

and the V-port will no longer move.

9. Grease exterior of cartridge above O-ring with

supplied low temp, high load, low RPM grease such

as Mobilith SHC PM 460 or similar.

10. Check the base of the actuator to ensure the set

screws are not protruding past the I.D. of the threaded

ring. If necessary, back the set screws out to prevent

interference during installation.

11. Install new actuator onto cartridge. Press down firmly

on the top of the actuator to ensure it fully seats. The

gap between the base of the actuator and bonnet/

cartridge should be less than 1/16”.

12. Rotate actuator to orient display in desired position

and torque the 3 set screws at base to 4 in-lb using

3/32” hex key.

13. Connect the red and green cables to the actuator.

14. Upon power-up the valve will automatically calibrate.

SERVICE AND MAINTENANCE

MCXV MOTORIZED CONTROL VALVE

FIGURE 33

6HDW

6HDW:DVKHU

*DVNHW

&DUWULGJH$VVHPEO\

6HW6FUHZV

$FWXDWRU

&DEOHVFRQQHFW

WRRSSRVLWHVLGH

RIDFWXDWRUQRW

VKRZQ

1HHGOH

Needle/V-port

AssemblyKit

(includesgasketkit)

Cartridge

AssemblyKit

(gasketkit,cartridge,

grease)

SMVtoMCV

ConversionKit**

(Actuator,DongleCable,

Bonnet,Bolts,Cartridge

Gasket,BonnetO-ring,

Grease)

SMVPowerCloseto

MCVPowerBackup

ConversionKit**

75-1347*** 75-1347withHUPS***

75-1348*** 75-1348withHUPS***

75-1347*** 75-1347withHUPS***

75-1348*** 75-1348withHUPS***

NOTE:GasketsandO-ringsshouldbereplacedwithnewiftheyareremovedfromvalve.Recommendtolubricatenewgaskets/O-ringswithoilpriortoinstalling.Bolts

shouldhaveanW-seizeapplied.

* Includesstrainer

**All SMV to MCV conversion kits REQUIRE MCT to be available for conversion

*** All 3” and 4” SMV to MCV conversion kits REQUIRE a V-port kit to be requested separately

Loading...

Loading...