39

R649c

SEPTEMBER 2018

OPERATION

The valve is driven by a motor and electronics that are

placed inside of an IP67 watertight rated housing. Upon

receiving an input signal, the motor shaft rotates and

transfers the force via a magnetic coupling to a threaded

stem. This cartridge stem directly drives the valve

V-port to open or closed based on the incoming signal.

The actuator can run on incoming voltage of either 24VAC

or 24VDC. This is provided via two wires on the 5 pin

connector. Upon power-up the valve will run through a

self-calibration process. The actuator can be configured

into 1 of 2 operational modes: modulating or slow/

open close based on the wiring of the 8 pin connector

along with the menu selection. There are 2 additional

wires on the 8 pin connector that provide 0/4-20mA

feedback of the valve V-port position. The feedback

does not have to be connected to operate the valve.

To operate in the modulating mode, a milliamp or voltage

input control signal must always be maintained to keep the

V-port in position. A loss of signal or a signal out of range

will drive the valve closed and display an error code. When

the signal is present, the V-port will move and stay at that

location until the input signal changes. If loss of input power

occurs, the valve remains in its current position, unless the

valve is equipped with HUPS (Hansen power backup system).

To operate in the slow open/close solenoid mode, a relay

contact is required as a means of an input signal to fully

open or close the valve. No external voltage is needed

to power the relay signal. As a default, when the relay

is closed the valve is closed. A loss of signal will drive

the valve closed. If loss of input power occurs, the valve

remains in its current position, unless the valve is equipped

with HUPS.

ELECTRICAL INFORMATION & WIRING

The Motorized Control Valve will take either a 24VAC or

24VDC input voltage from an NEC Class 2 source and

either a voltage, current, or relay input control signal. It

is recommended to use a separate power supply from the

main supply for the current and voltage input signal to

maintain signal integrity. A dedicated incoming voltage

supply must be sized properly to deliver the proper amount

of voltage and current to actuator. A transformer rated at

24VA per valve or a power supply rated at .8A per valve

will be sufficient.

The incoming control signal can be wired and configured

as any of the following: 4-20mA, 0-20mA, 0-5VDC, 0-10VDC,

1-6VDC, and a relay closed contact. The output feedback

signal of the valve position can be configured as 4-20mA

or 0-20mA.

ELECTRICAL MAINTENANCE

Check calibration and HUPS function on a routine basis.

Check controller and controller wiring for corrosion and

proper connection.

CABLE CONNECTIONS

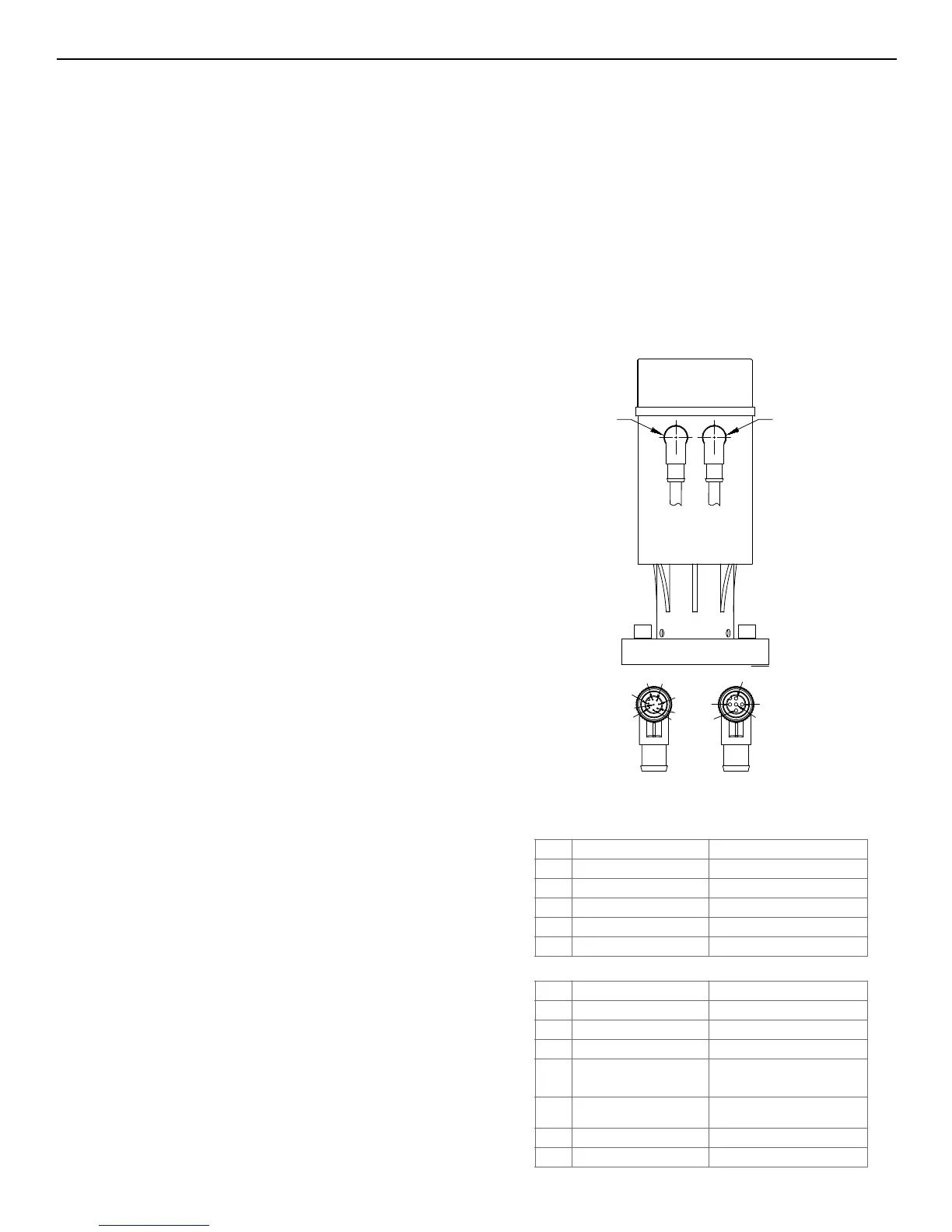

There are 2 distinct connection points that reside on the

MCV actuator. Both are M12 male connectors. The power

input consists of a 5 pin keyed connector and the control

signal consists of an 8 pin keyed connector.

The MCV comes standard with 6.5ft (2m) long cables with

M12 female heads. The power input cable consists of a

5 pin head and 22AWG wires. The control signal consists

of an 8 pin head and 24AWG wires. The standard cables

come with flying leads. When an SMV to MCV conversion

kit is purchased for a modulating valve, the cable dongle

will come equipped a connection that will plug into to

existing wiring.

8 PIN SIGNAL

5 PIN POWER

5

2

3

1

4

M12 8-PIN

FEMALE

3

4

5

1

2

8

7

6

M12 5-PIN

FEMALE

GREEN

RED

Under Electrical Information & Wiring section on MCV Bulletin Page 15 –

CABLE CONNECTIONS

There are 2 distinct connection points that reside on the MCV powerhead. Both are M12 male connectors. The

power input consists of a 5 pin keyed connector and the control signal consists of an 8 pin keyed connector.

The MCV comes standard with 6.5ft (2m) long cables with M12 female heads. The power input cable consists of a 5

pin head and 22AWG wires. The control signal consists of an 8 pin head and 24AWG wires. The standard cables come

with flying leads. When an SMV to MCV conversion kit is purchased for a modulating valve, the cable dongle will

come equipped a connection that will plug into to existing wiring.

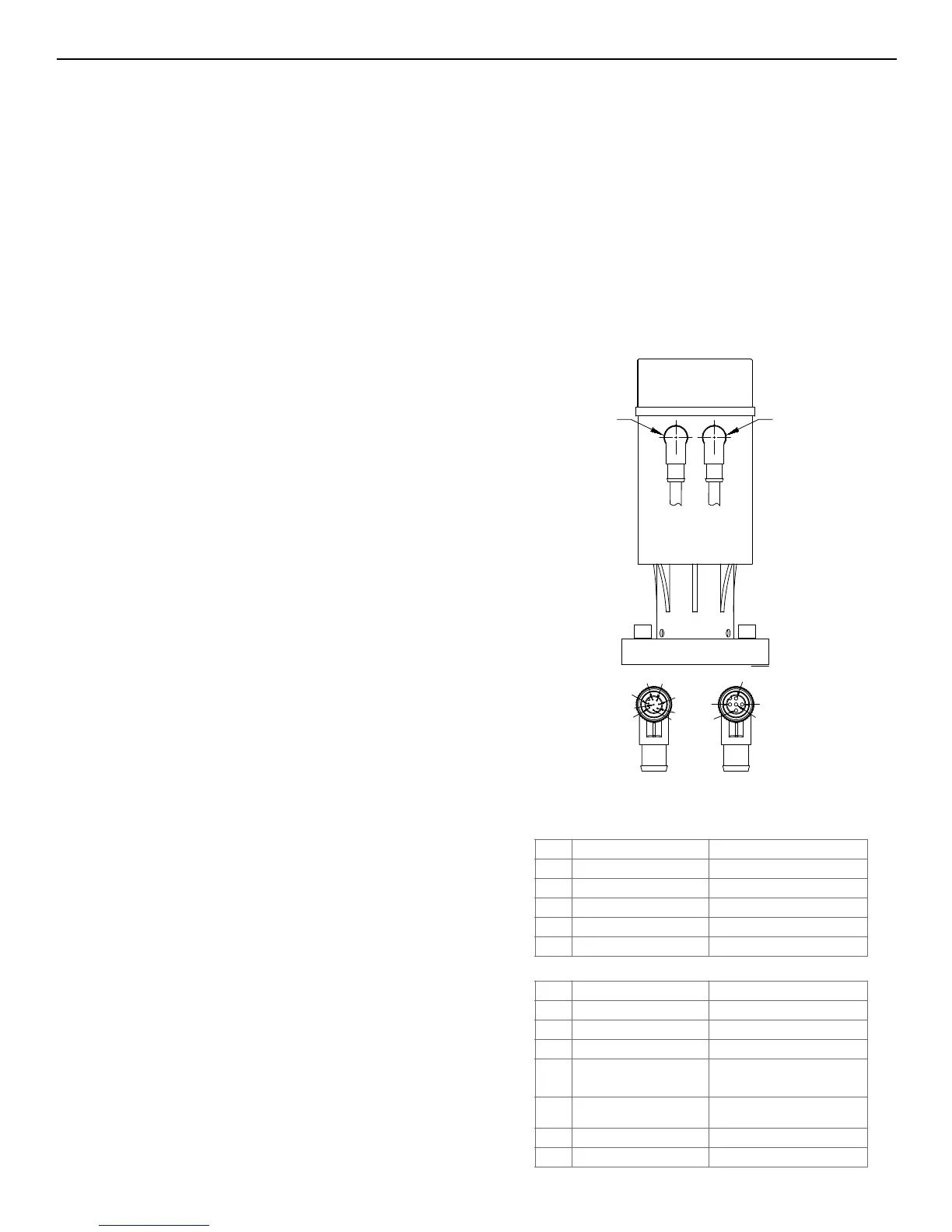

M12 - 8 Pin Connector M12 - 5 Pin

Connector

Power Connector – 5 Pin Red Cable

Signal Connector – 8 Pin Green Cable

Pin # Wire Color Description

1 Brown Not Used

2 White Not Used

3 Blue (+) Backup Power Supply

4 Black (+) 24VDC/24VAC

5 Gray (-) 24VDC/24VAC

Pin # Wire Color Description

1 White Not Used

2 Brown (-) 4-20mA Feedback Signal

3 Green (+) 4-20mA Feedback Signal

4 Yellow (-) Input Signal/Ground

A

dd in (Voltage Modulating, Current Modulating, Slow/Open Close) wiring diagrams after this section.

The Motorized Control Valve can be wired to an optional power backup system that will control the valve to a user

defined location upon a loss of the incoming voltage. These locations of fully open, fully closed, or another open

position can all be programmed through the user interface display. The Uninterruptable Power Supply (UPS) consists

of a voltage monitoring system as well as an integrated battery. The optional UPS when combined with an

appropriately sized DC power supply can run up to 3 Motorized Control Valves. If the incoming line voltage drops

below 19 volts and the power backup system is active, the system will switch over to use the battery power. This

UPS mode is indicated by a slow flashing green LED as seen on the diagram below. The RED illuminate when there is

an issue or the battery needs to be replaced. Once the incoming voltage level is restored, the valve will

automatically return to normal control mode.

HUPS LED Mode Indicator – Green LED

HUPS LED Alarm Indicator – Red LED

5 Gray (+) 0/4-20mA Input Signal

6 Pink (+) 0-5/10VDC & Relay Input

Signal

7 Blue Not Used

8 Red Not Used

FIGURE 30

MOTORIZED CONTROL VALVE OPERATION

Loading...

Loading...