20

R649c

SEPTEMBER 2018

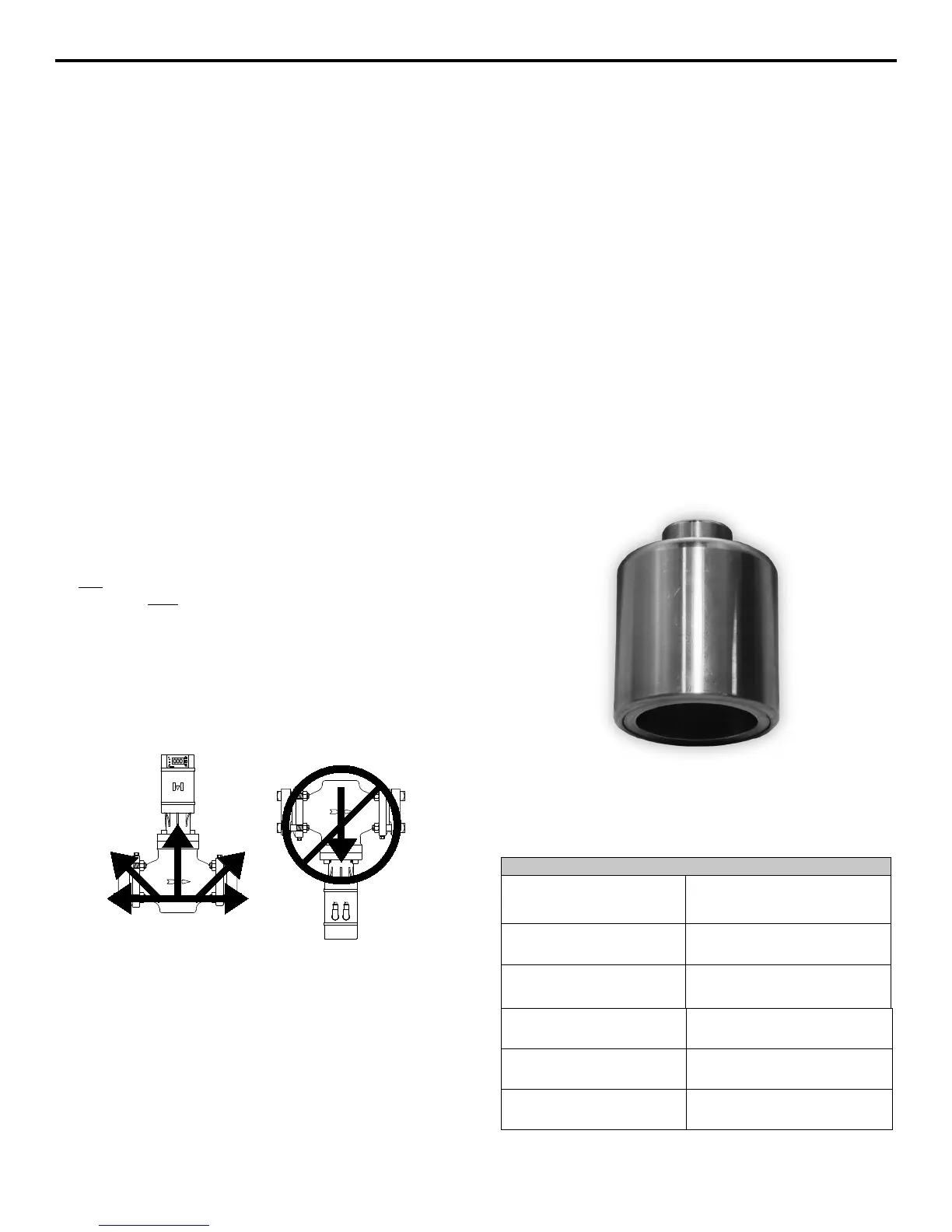

MANUAL CONTROL TOOL (MCT)

The V-port can be manually actuated by using the Manual

Control Tool (MCT), see Figure 14. To utilize the MCT, the

actuator would need to be removed from the valve. This

can be done by first removing the cables plugged into

the actuator, power (red) cable followed by the signal

(green) cable. The valve v-port will remain in the same

position it was at when cable was unplugged. Remove

the actuator by loosening the three set screws at the

base. DO NOT REMOVE THE BONNET. Place the MCT

over the cartridge and turn the MCT clockwise to open or

counterclockwise to close. Before re-installing rotate the

MCT counterclockwise until the V-port is closed. Refer

to TABLE 25 for the number of turns to fully actuate the

valve. MCT is required to install V-port fully onto cartridge

or remove V-port from cartridge (this includes during

converting from SMV to MCV).

To reinstall the actuator, follow the instructions on page 21.

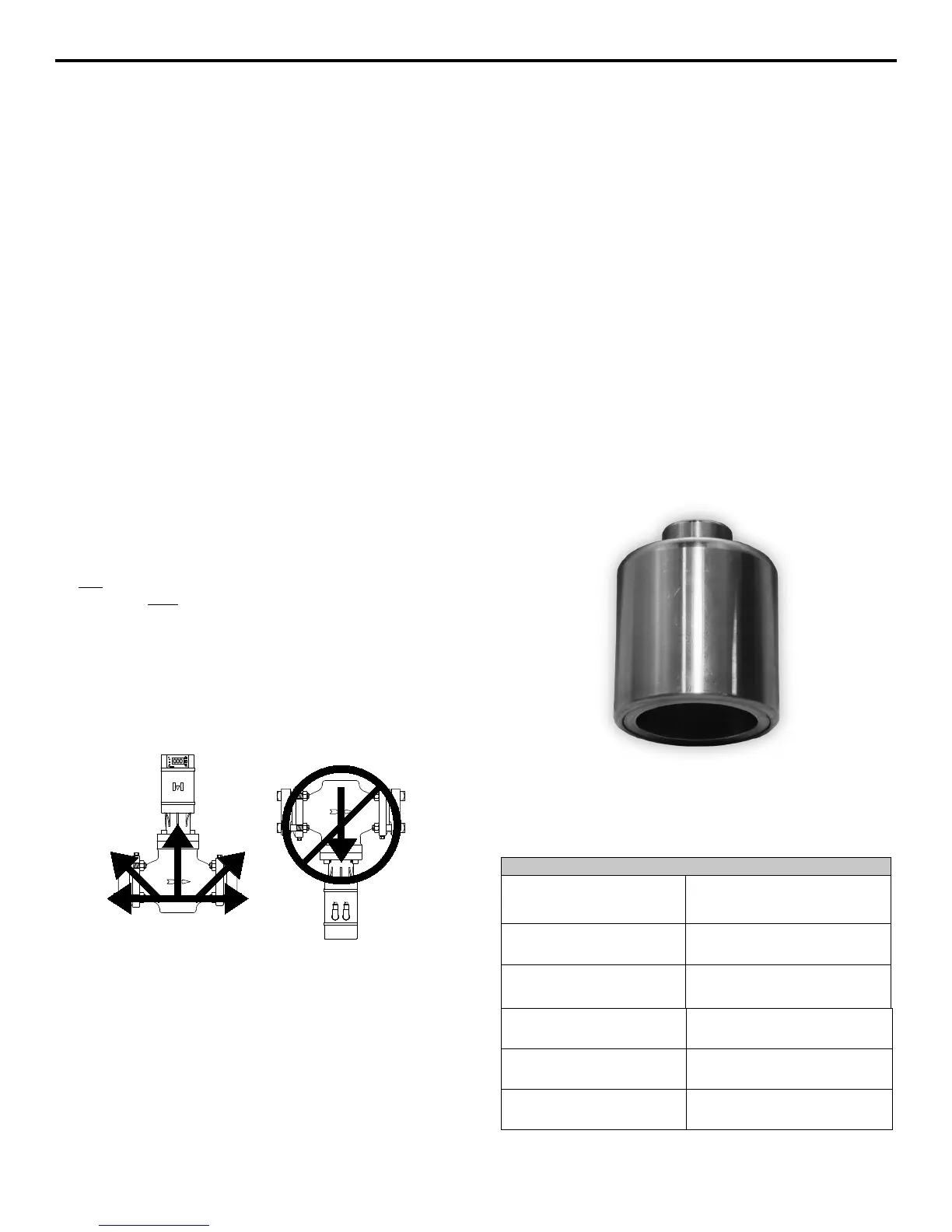

INSTALLATION OVERVIEW

Protect the interior of valve from dirt and moisture during

storage and installation. Valve should be installed so

that the arrow on the valve body is in direction of normal

refrigerant flow. System should be free from dirt, weld slag

and rust particles. A 60 mesh, close-coupled strainer is

available for installation at inlet of valve for 3/4˝, 1˝ and

1-1/4˝. Do not close-couple strainers to 1-1/2˝ through 2˝

Motorized Control Valves.

Please note: Valve will not backflow if in closed position.

Do not install check valves upstream of the Motorized

Control Valve without hydrostatic pressure relief. Do not

close the hand valve on inlet or outlet without making sure

valve is in the open position.

1/4˝ NPT Gauge/Purge port connections are provided on

the inlet and outlet of the 3/4˝ thru 2˝ valves standard.

Pipe sizing, valve placement, rating, anchoring, and similar

prudent precautions should be taken to ensure “liquid

hammer” will not occur when valves open or close.

For proper flange gasket sealing, care must be taken

when threading or welding to assure flanges are parallel

to each other and perpendicular to pipe. Also, gaskets

should be lightly oiled and all bolts should be lubricated

with an anti-seize and must be tightened evenly.

Protect cables during installation.

Do not mount the valve with the motor in the down position.

The valve will only operate properly if the motor is mounted

in a horizontal or upright position. Refer to diagrams

below. Horizontal mounting of motor is satisfactory if oil

and dirt are controlled.

MOTORIZED CONTROL VALVE INSTALLATION

TABLE 25

NUMBER OF TURNS TO ACTUATE VALVE

VALVE PORT SIZE

INCH

(MM)

NUMBER OF TURNS

1/16” THRU 9/32”

(2 THRU 7)

6

3/4” THRU 1-1/4”

(20 THRU 32)

7

1-1/2” THRU 2”

(40 THRU 50)

12

3”

(80)

18

4”

(100)

20

FIGURE 14

Loading...

Loading...