TEC0020 2018JAN3 P/N: 630-00025 Rev D AL600 & AL690 Hybrid Installation & Owner's Manual

13

SECTION 2 : INSTALLER

Wiring the Vehicle

Figure 13-2

Figure 13-4

Figure 13-1

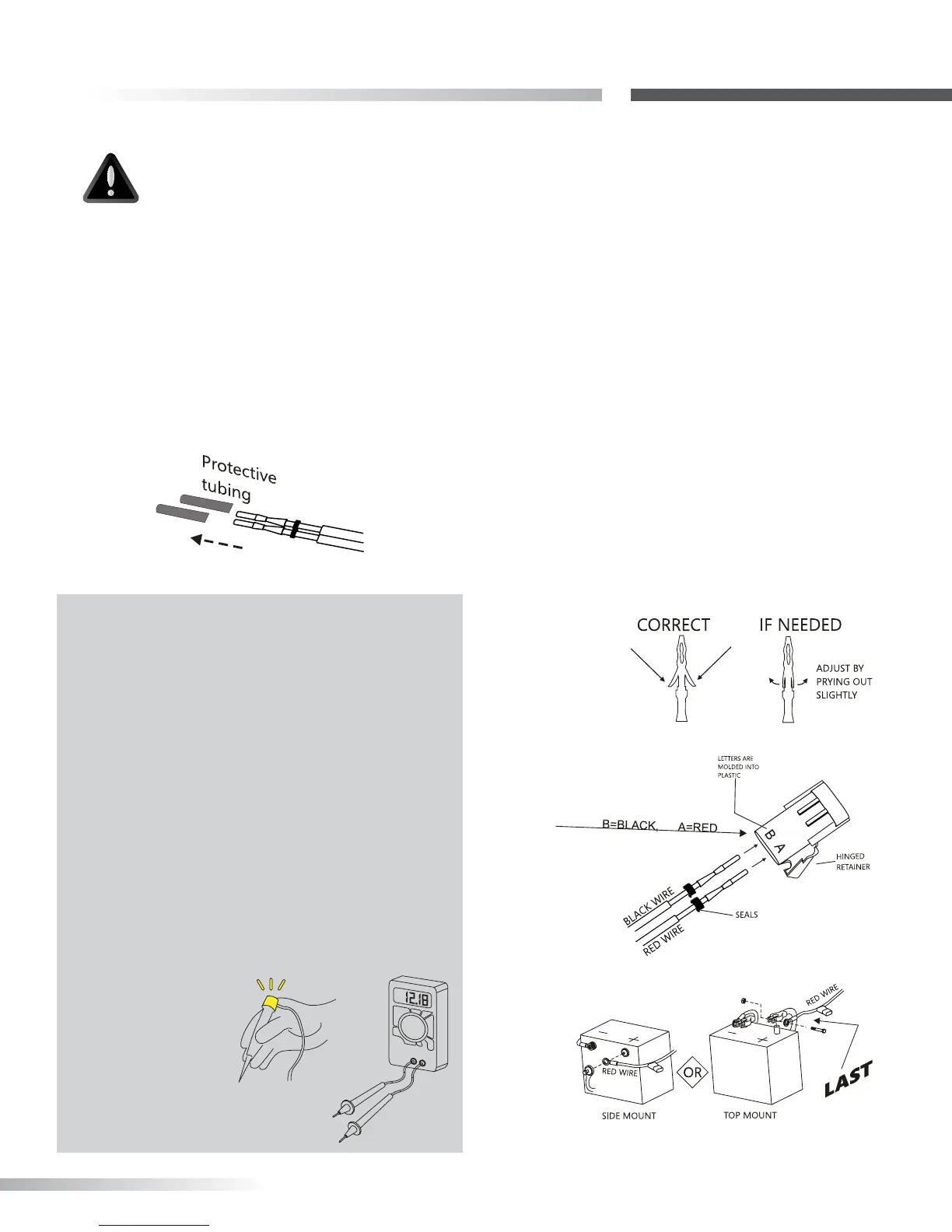

5. Inspect the pin’s retaining anges. The anges

may have been deformed while being run through

the vehicle. These are critical to secure the pins

inside the connector. Adjust as needed. [Figure 13-2]

6. Flip open end connector’s hinged retainer.

• Insert pins as shown. [Figure 13-3]

• Verify the wires cannot be pulled out by

moderately pulling on the wires. Be sure rubber

seals are inside the back of the connector.

• Close the hinged retainer.

• Plug connector into lift.

7. Last, attach red wire to the positive terminal on the

battery. [Figure 13- 4]

NOTE: Troubleshooting with a test light or voltage

meter may give a false indication.

When you probe for 12 volts, the reading may

indicate a connection, even if the connection

is not necessarily sucient. The lift’s motor can

draw up to 20 Amps at some points, requiring all

of the available wire to ow proper current. Poor

connections are the #1 problem associated with a

slow, intermittent, warm, poorly performing motor

which will also deteriorate prematurely.

If a single strand of a multi-strand wire is making

contact, 12V will appear on a meter or test light, but

it will not allow the motor to operate. It is always

best to test both current and voltage, or run the

motor with known

good shop battery or

power source when

troubleshooting.

VOLTAGE

METER

AUTOMOTIVE

TEST LIGHT

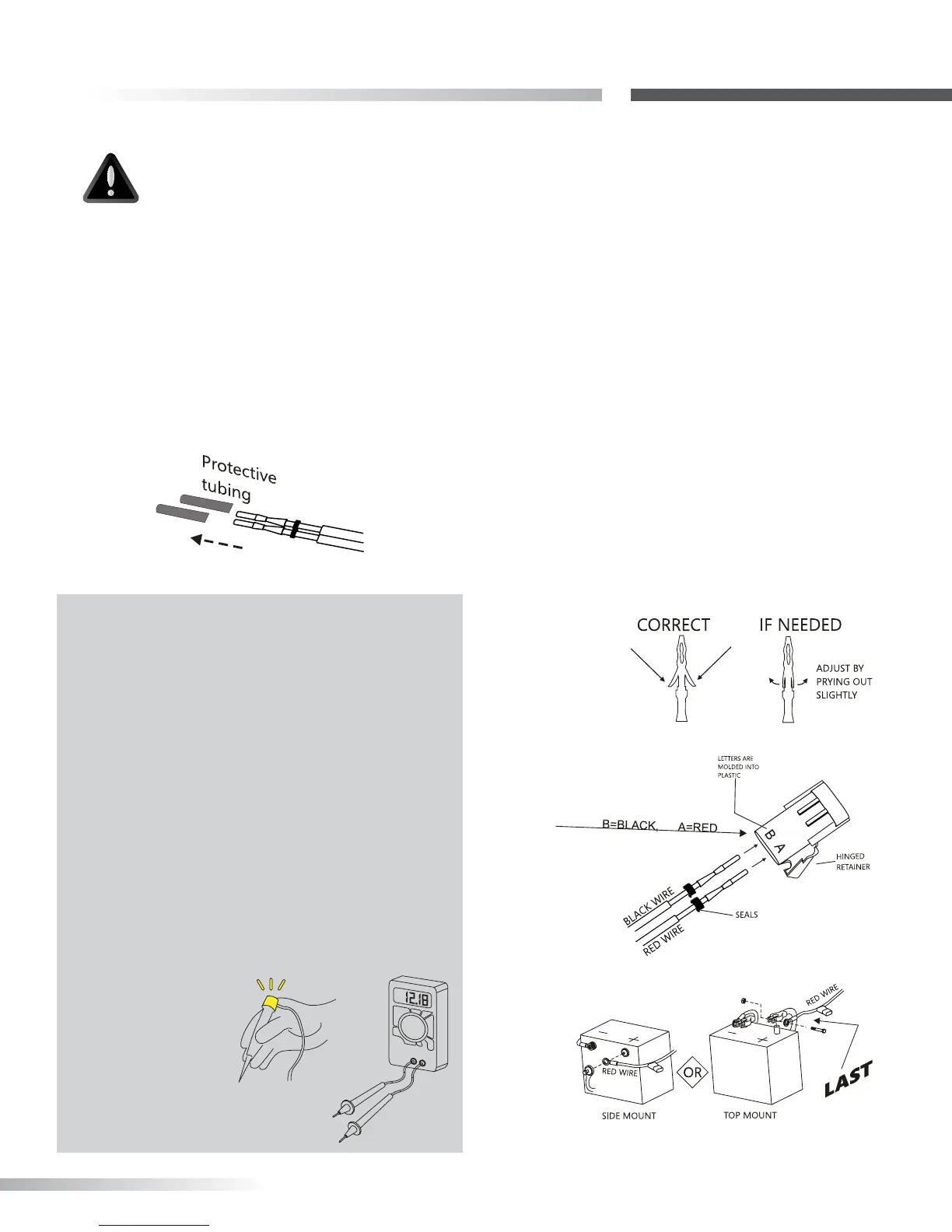

4. When harness is through the vehicle, remove

the pin’s protective tubing. [Figure 13-1]

Figure 13-3

CAUTION

If the harness is too long for the vehicle,

coil the excess wire and secure it to

the vehicle frame with the supplied tie

wraps.

Do NOT cut or shorten the harness

Loading...

Loading...