1.58

1.58

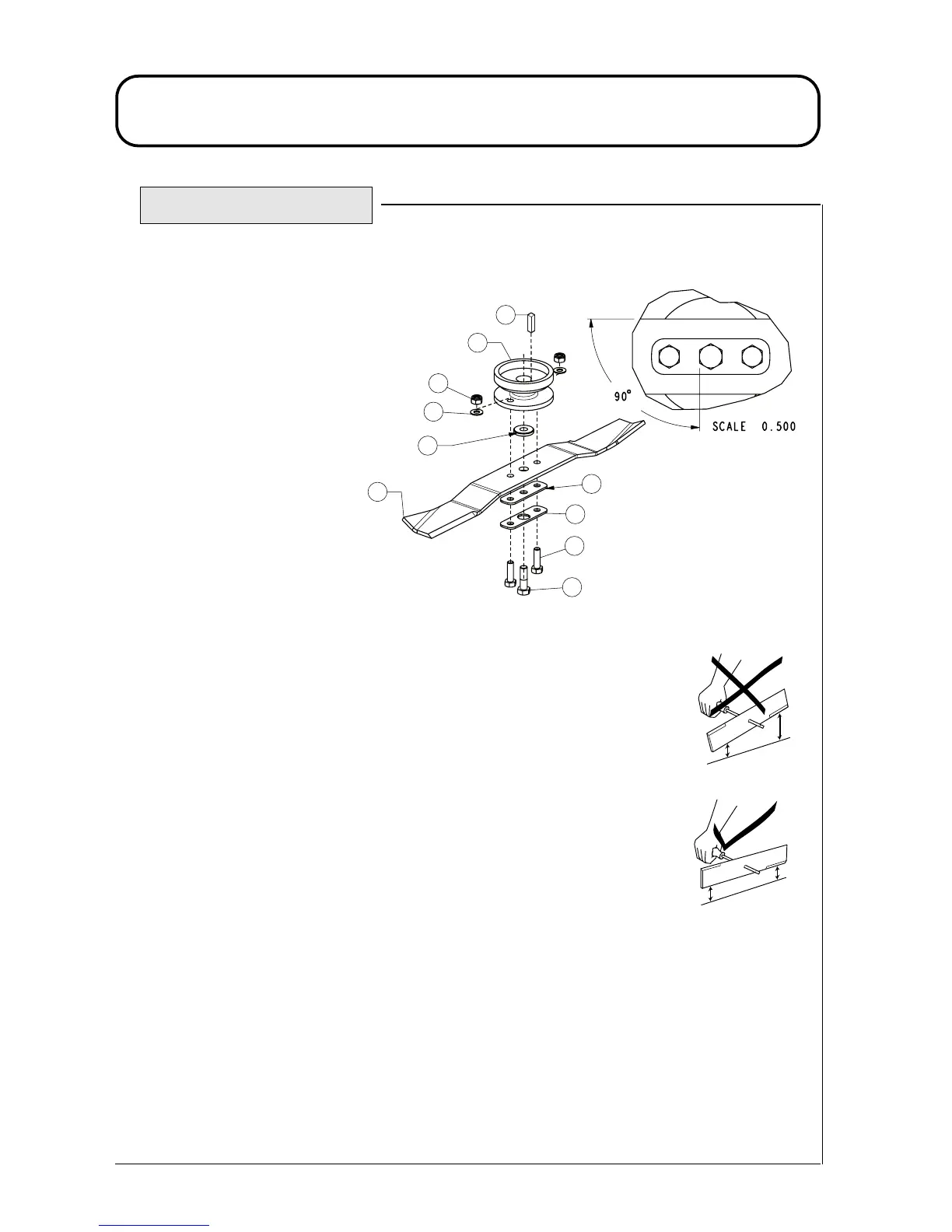

Regularly check that the cutterblade securing bolts (items 1 and 2) are tightened to the

specified torque and re-new cutterblade - lockplate.

Bolt (item 1) - Torque to 70-95Nm (52-70 Ibf.ft).

Bolt (item 2) - Torque to 40-55Nm (30-40 Ibf.ft).

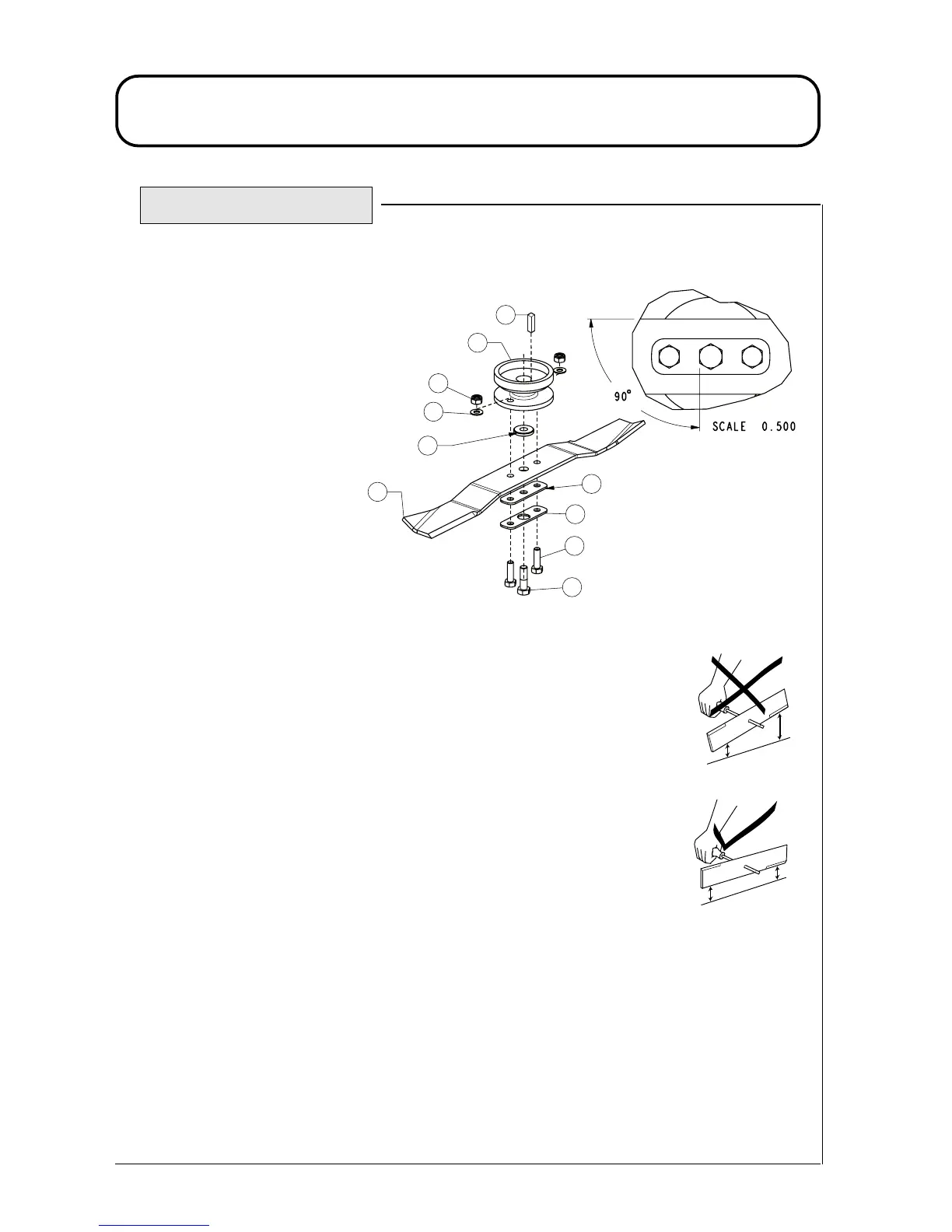

Ensure that each cutterblade is balanced. Use a screw driver with a round shaft to sup-

port the cutterblade through its centre hole. Hold the cutterblade horizontal and then

release. A balanced cutterblade will remain horizontal. If the cutterblade is not bal-

anced the heavy end will rotate downwards. Regrind the heavy end until the cutterblade

is correctly balanced.

MAINTENANCE

CUTTERBLADES

1. Bolt M12 x 40 HT/10.9

2. Lockplate - R324T Blade Bolt

3. Nut M10 x 1.5 NYL INS

4. Screw M10 x 35

5. Lockplate Spacer (Zine)

6. Washer m10 x 21 x 1.45 form B

7. Cutterbar Spacer

8. Boss Cutterbar Mounting

9. Key

10. Cutterbar

Loading...

Loading...