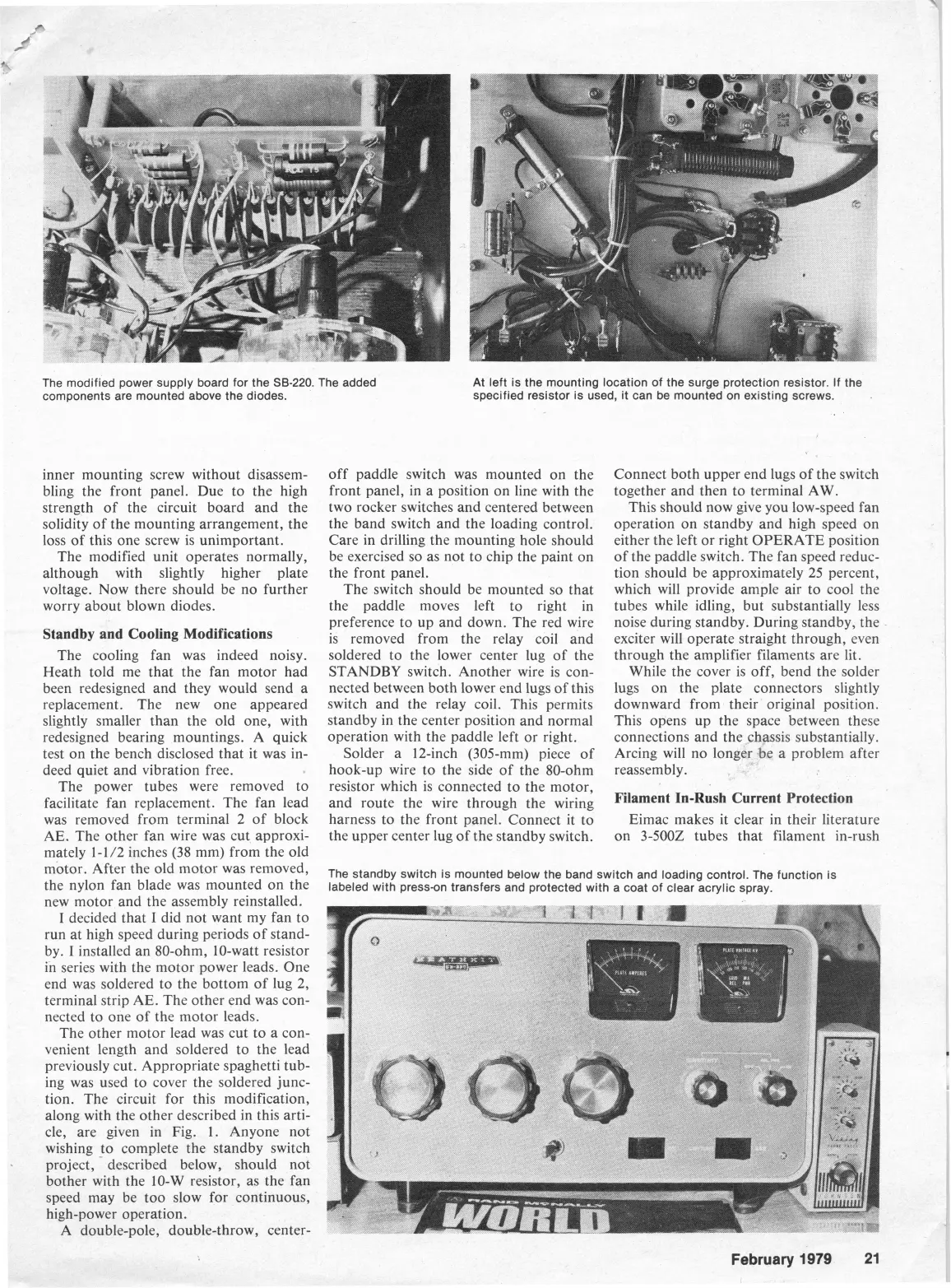

The modified power supply board for the SB-220. The added

components are mounted above the diodes.

inner mounting screw without disassem-

bling the front panel. Due to the high

strength of the circuit board and the

solidity of the mounting arrangement, the

loss of this one screw is unimportant.

The modified unit operates normally,

although with slightly higher plate

voltage. Now there should be no further

worry about blown diodes.

Standby and Cooling Modifications

The cooling fan was indeed noisy.

Heath told me that the fan motor had

been redesigned and they would send a

replacement. The new one appeared

slightly smaller than the old one, with

redesigned bearing mountings. A quick

test on the bench disclosed that it was in-

deed quiet and vibration free.

The power tubes were removed to

facilitate fan replacement. The fan lead

was removed from terminal

2

of block

AE.

The other fan wire was cut approxi-

mately 1-1/2 inches (38 mm) from the old

motor. After the old motor was removed,

the nylon fan blade was mounted on the

new motor and the assembly reinstalled.

I

decided that

I

did not want my fan to

run at high speed during periods of stand-

by.

I

installed an 80-ohm, 10-watt resistor

in series with the motor power leads. One

end was soldered to the bottom of lug 2,

terminal strip AE. The other end was con-

nected to one of the motor leads.

The other motor lead was cut to a con-

venient length and soldered to the lead

previously cut. Appropriate spaghetti tub-

ing was used to cover the soldered junc-

tion. The circuit for this modification,

along with the other described in this arti-

cle, are given in Fig. 1. Anyone not

wishing to complete the standby switch

-

project, described below, should not

bother with the 10-W resistor, as the fan

snoed may be too slow for continuous,

:h-power operation.

4

double-pole, double-throw, center-

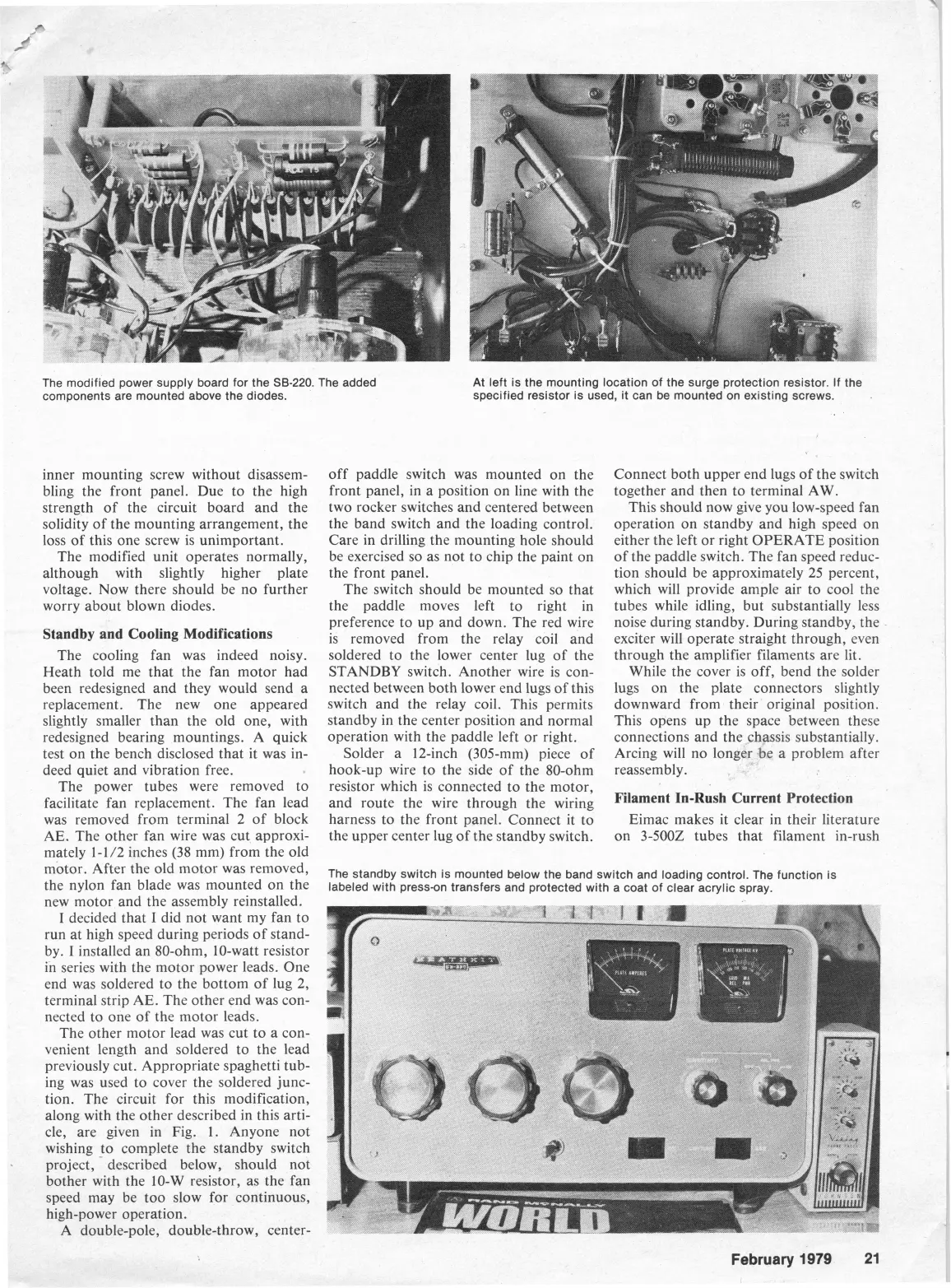

At left is the mounting location of the surge protection resistor. If the

specified resistor is used, it can be mounted on existing screws.

.

off paddle switch was mounted on the

front panel, in a position on line with the

two rocker switches and centered between

the band switch and the loading control.

Care in drilling the mounting hole should

be exercised so as not to chip the paint on

the front panel.

The switch should be mounted so that

the paddle moves left to right in

preference to up and down. The red wire

is removed from the relay coil and

soldered to the lower center lug of the

STANDBY switch. Another wire is con-

nected between both lower end lugs of this

switch and the relay coil. This permits

standby in the center position and normal

operation with the paddle left or right.

Solder a 12-inch (305-mm) piece of

hook-up wire to the side of the 80-ohm

resistor which is connected to the motor,

and route the wire through the wiring

harness to the front panel. Connect it to

the upper center lug of the standby switch.

Connect both upper end lugs of the switch

together and then to terminal AW.

This should now give you low-speed fan

operation on standby and high speed on

either the left or right OPERATE position

of the paddle switch. The fan speed reduc-

tion should be approximately 25 percent,

which will provide ample air to cool the

tubes while idling, but substantially less

noise during standby. During standby, the

exciter will operate straight through, even

through the amplifier filaments are lit.

While the cover is off, bend the solder

lugs on the plate connectors slightly

downward from their original position.

This opens up the space between these

connections and the chassis substantially.

Arcing will no longer be a problem after

reassembly.

Filament In-Rush Current Protection

Eimac makes it clear in their literature

on

3-5002 tubes that filament in-rush

The standby switch is mounted below the band switch and loading control. The function is

labeled with press-on transfers and protected with a coat of clear acrylic spray.

February

1979 21

Loading...

Loading...