1

an open-ended chassis equipped with a

1

'

single, 6-inch-diameter fan blade that could

I

simultaneously blow cooling air above and

below the chassis.

I

To position the four hot filament pins

optimally in the under-chassis airflow, the

1

pair of tube sockets was mounted with the

I

two pairs of filament pins facing each

other. This optimally positions the hottest

1

parts in front of the tips of the fan blades.

I

The cooling-system design is brilliantly

simple. It's relatively quiet and works well.

1

Reports of tube-pin solder melting in

I

SB-220 amplifiers are very rare (with the

exception of cases where the fan-motor

1

bearings seized because they were never

I

oiled!). On the other hand,

I

have heard

of many 3-500Z-pin solder-melting

epi-

I

sodes in other amplifiers that used centri-

fugal blowers and air-system-chimney

1

cooling.

I

One weakness in the SB-220's cooling

system is that the infrared radiation (heat)

1

reflected back into the tubes from the

I

bright aluminum surfaces adjacent and

parallel to the anodes shortens tube life.

I

This deficiency is easily corrected: After

removing the tubes, apply black liquid shoe

polish to the vertical aluminum surfaces

near the tubes.

Fan Oiling

An oversight in early SB-220s was the

failure to provide oil holes for the

fan-

motor bearings. This problem can be cor-

rected by drilling a small hole, no more

than

1/4

inch deep, above the front and rear

bearings. It's not necessary to remove the

fan motor to do this. The fan should be

lubricated at least annually with a thin,

non-gumming

oil such as Hoppe's

no.

1003.4.5 Insert a drop or two of such

oil into each hole. What isn't absorbed by

the felt wicks that surround the bearings

simply dribbles out.

More oil is not better,

just messier.

The easiest way to get the

desired amount of oil in the holes is to

apply the oil with a disposable insulin

syringe (available at most drug stores); each

unit on such a syringe is equivalent to

approximately one drop of oil.

Premature Filter-Capacitor Failure

Aluminum-electrolytic filter capacitors

are very sensitive to heat. For every

10-"C

increase above room temperature, capaci-

tor life expectancy is approximately

halved.

The electrolytic filter capacitors in the

SB-220 are subjected to high heat during

normal operation, mostly because of their

proximity to their eight associated 30-kfl

voltage-equalizing/bleeder

resistors. During

transmit, another (minor) source of capa-

citor heating is the 60-Hz ripple current

flowing through each capacitor.

The capacitor-heating problem is com-

pounded because cooling air does not reach

the capacitors. In some cases, the heat

present partially melts the ends of the capa-

citor holders that are nearest to the 30-kfl

resistors!

Heat dissipated by these resistors can be

reduced by about 70% by replacing them

with

100-kQ, 2- or 3-W, 5%-tolerance film

resistors. Other resistance values may be

used, up to roughly 150

kfl, provided that

the resistors are rated to withstand the volt-

age applied to them and the resistor values

are within 5% of each other. I do not

recommend using ancient 2-W

carbon-

composition resistors for this application.

They don't stay within their rated tolerance

as

they age. This simple modification greatly

prolongs the life of the electrolytic filter

capacitors.

Note: Increasing the equalizing-resistor

values also increases the capacitor

bleed-

down time after the amplifier is shut off.

Because this amplifier has a shorting HV

interlock that grounds the HV-positive lead

when the cover is removed, it's advisable

to wait until the front-panel voltmeter

indicates nearly

0

V before allowing the

interlock to short the

HV

line to the chas-

sis. Here's why: When the HV positive

is shorted to ground, the energy stored in

the filter capacitors is applied

directly

to

the grid-current-meter shunt resistor, R3

(0.82

Q),

which is the only HV-negative

path to chassis. The peak discharge current

can be substantial, and damage to the meter

shunt and movement can occur.

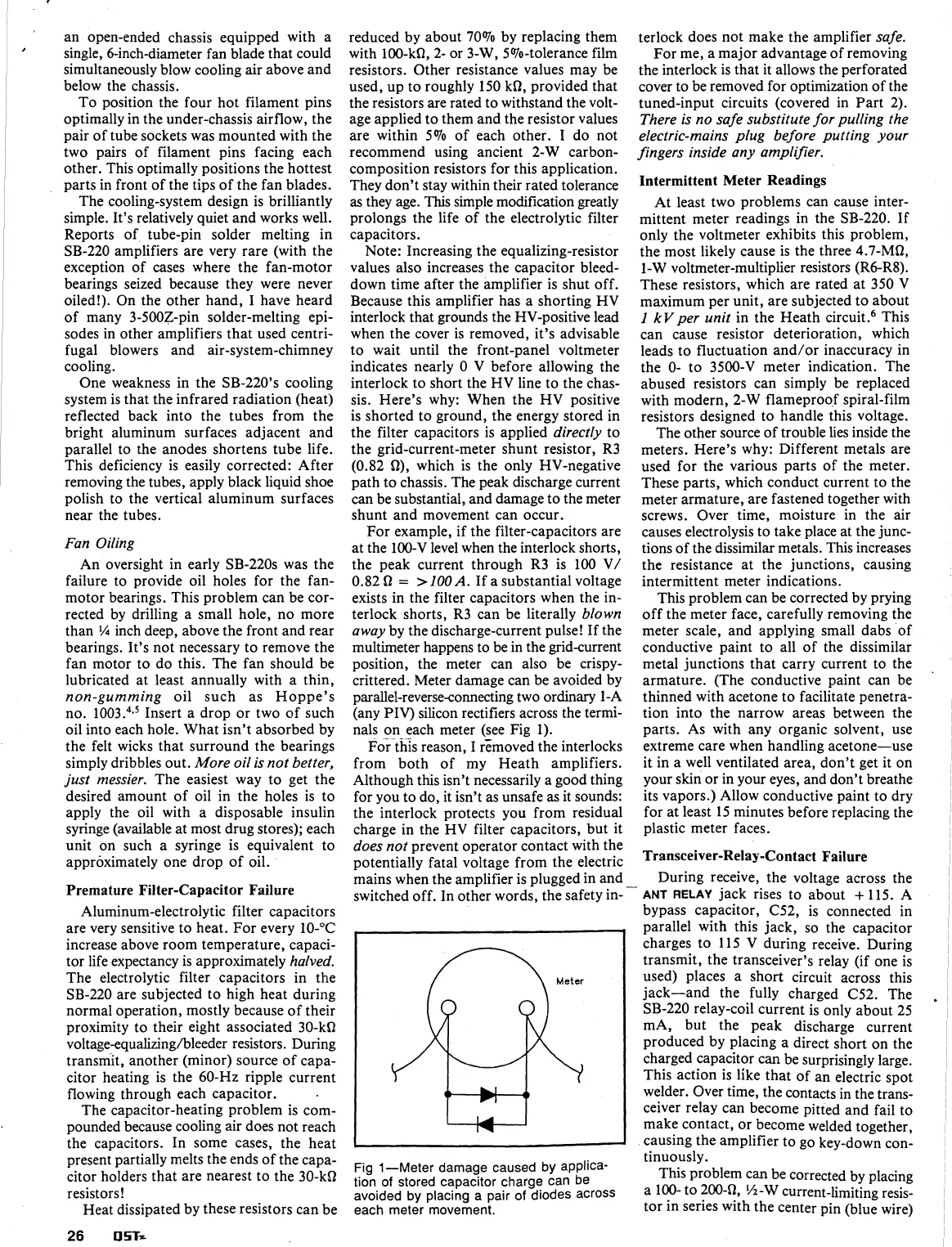

For example, if the filter-capacitors are

at the 100-V level when the interlock shorts,

the peak current through R3 is

100 V/

0.82 fl

=

>

I00

A.

If a substantial voltage

exists in the filter capacitors when the in-

terlock shorts, R3 can be literally

blown

away

by the discharge-current pulse! If the

multirneter happens to be in the grid-current

position, the meter can also be

crispy-

crittered. Meter damage can be avoided by

parallel-reverse-connecting two ordinary 1-A

(any

PIV)

silicon rectifiers across the termi-

nals on each meter (see Fig 1).

or

this reason, I removed the interlocks

from both of my Heath amplifiers.

Although this isn't necessarily a good thing

for you to do, it isn't as unsafe

as

it sounds:

the interlock protects you from residual

charge in the HV filter capacitors, but it

does not

prevent operator contact with the

potentially fatal voltage from the electric

mains when the amplifier is plugged in and

switched off. In other words, the safety

in-

Fig

1

-Meter damage caused by applica-

tion of stored capacitor charge can be

avoided

by

placing a pair of diodes across

each meter movement.

terlock does not make the amplifier

safe.

For me, a major advantage of removing

the interlock is that it allows the perforated

cover to be removed for optimization of the

tuned-input circuits (covered in Part 2).

There is no safe substitute for pulling the

electric-mains plug before putting your

fingers inside any amplifier.

Intermittent Meter Readings

At least two problems can cause inter-

mittent meter readings in the SB-220. If

only the voltmeter exhibits this problem,

the most likely cause is the three 4.7-Mfl,

1-W voltmeter-multiplier resistors (R6-R8).

These resistors, which are rated at 350 V

maximum per unit, are subjected to about

1

kVper unit

in the Heath circ~it.~ This

can cause resistor deterioration, which

leads to fluctuation and/or inaccuracy in

the 0- to

3500-V meter indication. The

abused resistors can simply be replaced

with modern, 2-W flameproof spiral-film

resistors designed to handle this voltage.

The other source of trouble lies inside the

meters. Here's why: Different metals are

used for the various parts of the meter.

These parts, which conduct current to the

meter armature, are fastened together with

screws. Over time, moisture in the air

causes electrolysis to take place at the junc-

tions of the dissimilar metals. This increases

the resistance at the junctions, causing

intermittent meter indications.

This problem can be corrected by prying

off the meter face, carefully removing the

meter scale, and applying small dabs of

conductive paint to all of the dissimilar

metal junctions that carry current to the

,

armature. (The conductive paint can be

thinned with acetone to facilitate penetra-

tion into the narrow areas between the

parts. As with any organic solvent, use

extreme care when handling acetone-use

it in a well ventilated area, don't get it on

your skin or in your eyes, and don't breathe

its vapors.) Allow conductive paint to dry

for at least 15 minutes before replacing the

plastic meter faces.

Transceiver-Relay-Contact Failure

-

During receive, the voltage across the

ANT

RELAY

jack rises to about

+

115. A

bypass capacitor, C52, is connected in

parallel with this jack, so the capacitor

charges to 115 V during receive. During

transmit, the transceiver's relay (if one is

used) places a short circuit across this

jack-and the fully charged C52. The

.

SB-220 relay-coil current is only about 25

mA, but the peak discharge current

produced by placing a direct short on the

charged capacitor can be surprisingly large.

This action is like that of

an electric spot

welder. Over time, the contacts in the trans-

ceiver

relay can become pitted and fail to

make contact, or become welded together,

causing the amplifier to go key-down con-

tinuously.

This problem can be corrected

by placing

a

100-

to 200-fl,

!h-W

current-limiting resis-

tor in series with the center

pin (blue wire)

Loading...

Loading...