to

K1

Coil.

Fig

2

loo-

200

n

C52

0.02

pF

ANT

RELAY

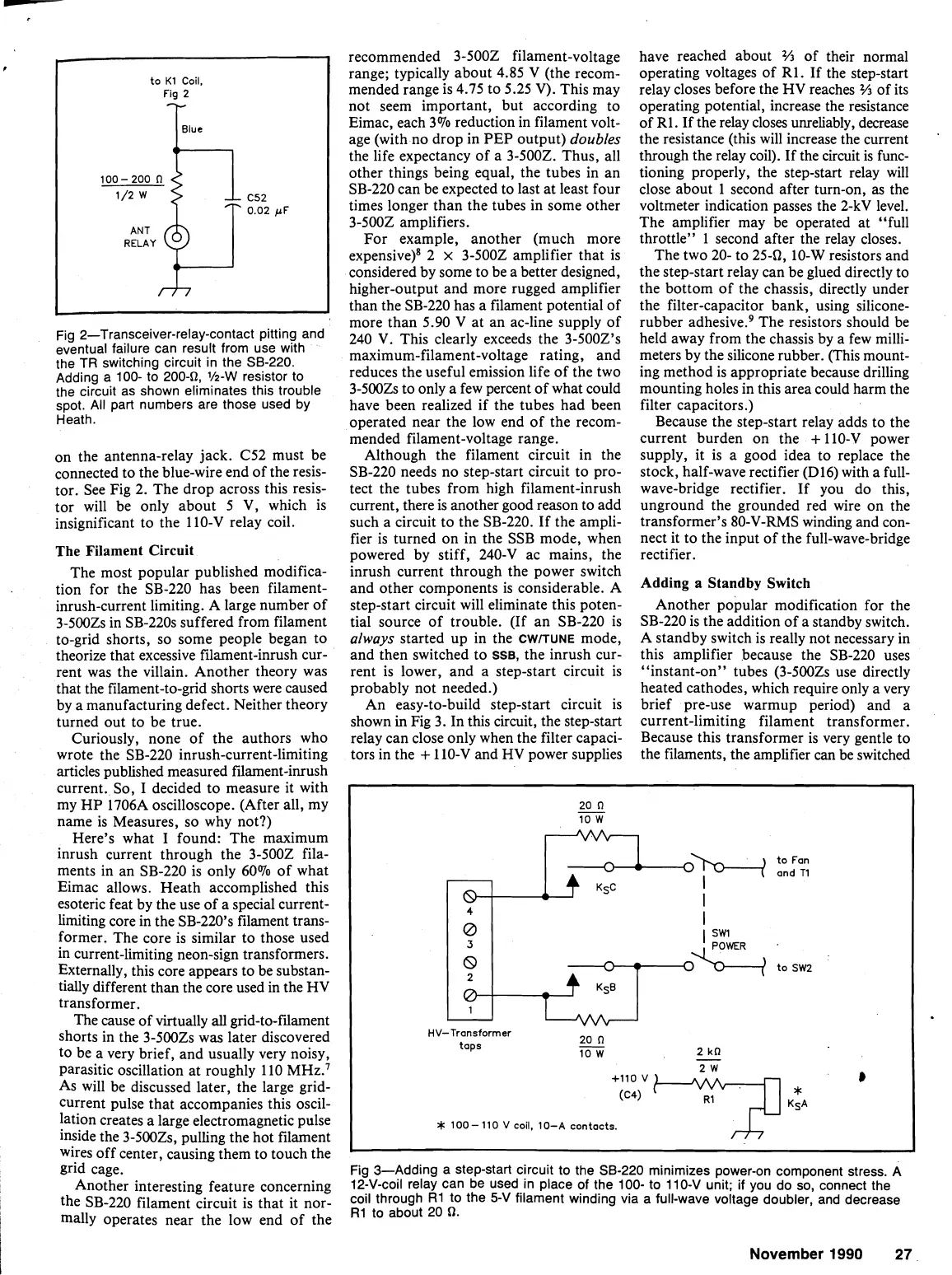

Fig 2-Transceiver-relay-contact pitting and

eventual failure can result from use with

the

TR

switching circuit

in

the SB-220.

Adding a 100- to 200-Q,

%-W

resistor to

the circuit as shown eliminates this trouble

spot. All part numbers are those used

by

Heath.

on the antenna-relay jack.

C52 must be

connected to the blue-wire end of the resis-

tor. See Fig 2. The drop across this resis-

tor will be only about 5 V, which is

insignificant to the 110-V relay coil.

The Filament Circuit

The most popular published modifica-

tion for the SB-220 has been

filament-

inrush-current limiting. A large number of

3-500Zs in SB-220s suffered from filament

to-grid shorts, so some people began to

theorize that excessive filament-inrush cur-

rent was the villain. Another theory was

that the filament-to-grid shorts were caused

by a manufacturing defect. Neither theory

turned out to be true.

Curiously, none of the authors who

wrote the SB-220 inrush-current-limiting

articles published measured filament-inrush

current. So, I decided to measure it with

my HP

1706A oscilloscope. (After all, my

name is Measures, so why not?)

Here's what

I

found: The maximum

inrush current through the

3-5002 fila-

ments in an SB-220 is only 60% of what

Eimac allows. Heath accomplished this

esoteric feat by the use of a special

current-

limiting core in the SB-220's filament trans-

former. The core is similar to those used

in current-limiting neon-sign transformers.

Externally, this core appears to be substan-

tially different than the core used in the HV

transformer.

The cause of

virtually

all

grid-to-filament

shorts in the

3-5002s

was

later discovered

to be a very brief, and usually very noisy,

parasitic oscillation at roughly 110

MHz.'

As will be discussed later, the large grid-

current pulse that accompanies this oscil-

lation creates a large electromagnetic pulse

inside the

3-500Zs, pulling the hot filament

wires off center, causing them to touch the

grid cage.

Another interesting feature concerning

the SB-220 filament circuit is that it nor-

mally operates near the low end of the

recommended 3-5002 filament-voltage

range; typically about 4.85 V (the recom-

mended range is 4.75 to 5.25 V). This may

not seem important, but according to

Eimac, each 3% reduction in filament volt-

age (with no drop in PEP output)

doubles

the life expectancy of a 3-5002. Thus, all

other things being equal, the tubes in an

SB-220 can be expected to last at least four

times longer than the tubes in some other

3-5002 amplifiers.

For example, another (much more

expensi~e)~ 2

x

3-5002 amplifier that is

considered by some to be a better designed,

higher-output and more rugged amplifier

than the SB-220 has a filament potential of

more than 5.90 V at an ac-line supply of

240 V. This clearly exceeds the 3-5002's

maximum-filament-voltage rating, and

reduces the useful emission life of the two

3-5002s to only a few percent of what could

have been realized if the tubes had been

operated near the low end of the recom-

mended filament-voltage range.

Although the filament circuit in the

SB-220 needs no step-start circuit to pro-

tect the tubes from high filament-inrush

current, there is another good reason to add

such a circuit to the SB-220. If the ampli-

fier is turned on in the SSB mode, when

powered by stiff, 240-V ac mains, the

inrush current through the power switch

and other components is considerable. A

step-start circuit will eliminate this poten-

tial source of trouble. (If an SB-220 is

always

started up in the

CWiTUNE

mode,

and then switched to

SSB,

the inrush cur-

rent is lower, and a step-start circuit is

probably not needed.)

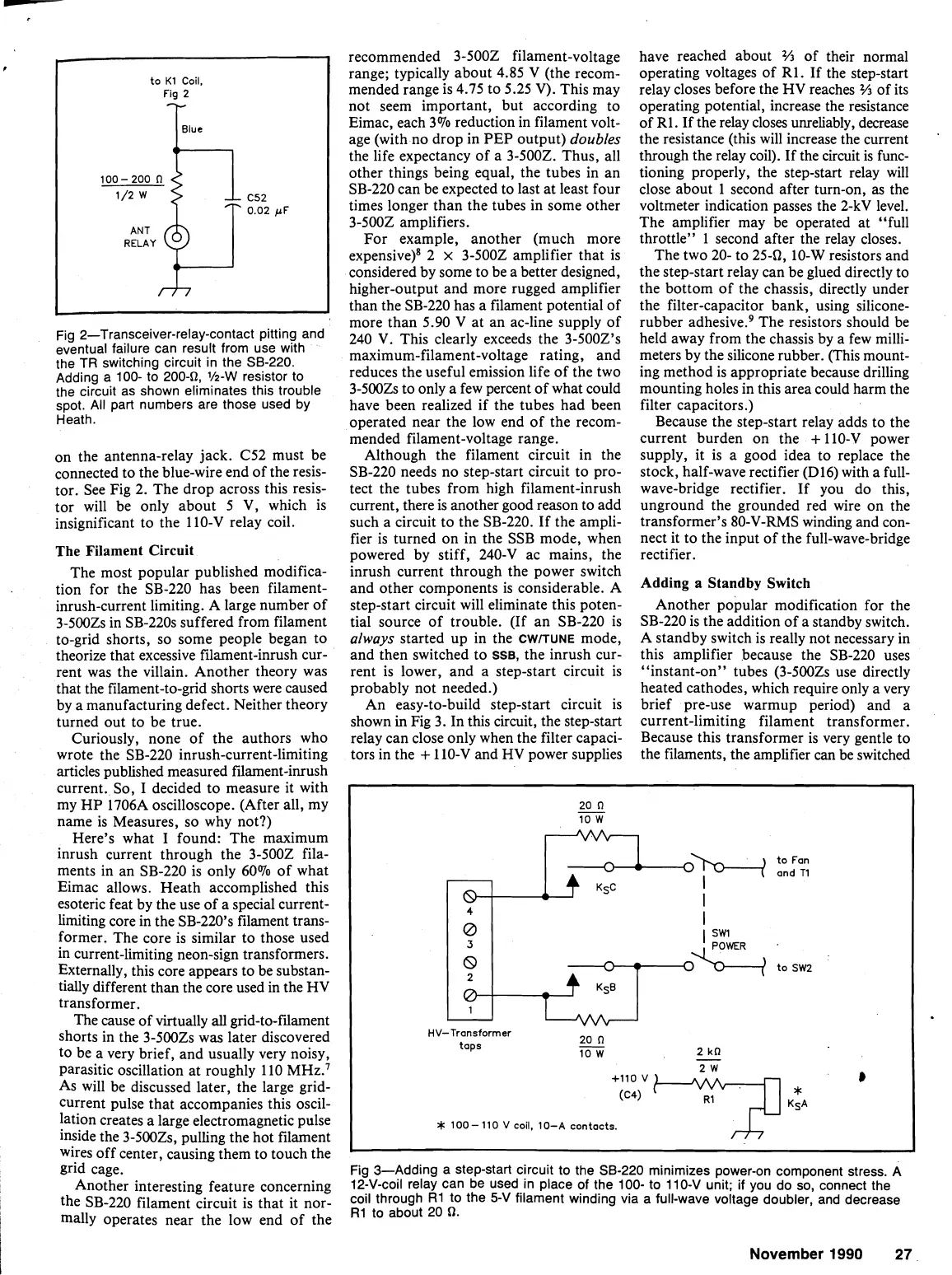

An easy-to-build step-start circuit is

shown

in

Fig 3. In this circuit, the step-start

relay can close only when the filter capaci-

tors in the

+

110-V and HV power supplies

have reached about

%

of their normal

operating voltages of

R1. If the step-start

relay closes before the HV reaches

%

of its

operating potential, increase the resistance

of

R1. If the relay closes unreliably, decrease

the resistance (this will increase the current

through the relay coil). If the circuit is func-

tioning properly, the step-start relay will

close about 1 second after turn-on,

as

the

voltmeter indication passes the

2-kV level.

The amplifier may be operated at "full

throttle" 1 second after the relay closes.

The two 20- to

254, 10-W resistors and

the step-start relay can be glued directly to

the bottom of the chassis, directly under

the filter-capacitor bank, using

silicone-

rubber adhe~ive.~ The resistors should be

held away from the chassis by a few milli-

meters by the silicone rubber. (This mount-

ing method is appropriate because drilling

mounting holes in this area could harm the

filter capacitors.)

Because the step-start relay adds to the

current burden on the

+

110-V power

supply, it is a good idea to replace the

stock, half-wave rectifier

(D16) with a full-

wave-bridge rectifier. If you do this,

unground the grounded red wire on the

transformer's 80-V-RMS winding and con-

nect it to the input of the full-wave-bridge

rectifier.

Adding a Standby Switch

Another popular modification for the

SB-220 is the addition of a standby switch.

A standby switch is really not necessary in

this amplifier because the SB-220 uses

"instant-on" tubes

(3-5002s use directly

heated cathodes, which require only a very

brief pre-use

warmup period) and a

current-limiting filament transformer.

Because this transformer is very gentle to

the filaments, the amplifier can be switched

Fig 3-Adding a step-start circuit to the SB-220 minimizes power-on component stress.

A

12-V-coil relay can be used

in

place of the 100- to 110-V unit;

if

you do so, connect the

coil through

R1 to the

5-V

filament winding via a full-wave voltage doubler, and decrease

R1

to about

20

0.

20

n

-

10

W

"

-

0-

:R

I

4

I

0

I

I

November

1990

27

3

8

2

0

1

SW1

h

0%

to

SW2

HV-Tronsformer

taps

20

n

-

2

kn

10

W

-

+IIO

v

8

*

100-

110

V

coil,

10-A

contacts.

Loading...

Loading...