*2232121*

2232121 English 33

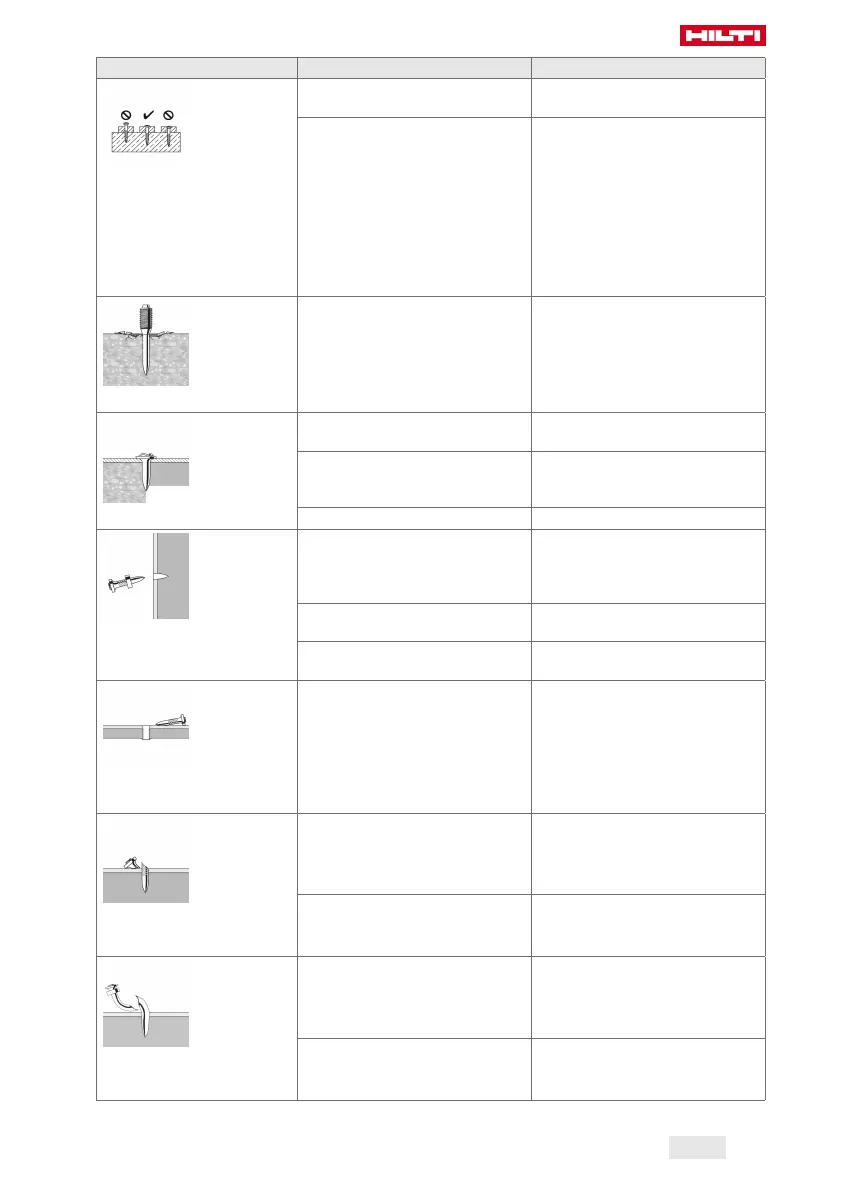

Malfunction Possible cause Action to be taken

The fastener is not driven

flush

A rebar is located just below the

concrete surface.

▶ Drive the fastener at a different

position.

Hard material (steel, concrete). ▶ Turn the selector ring for driving

energy to increase driving

energy.

▶ Use a shorter nail.

▶ Use a nail with a higher

application limit.

▶ For concrete: Use the DX-Kwik

method (predrilling) → see the

'Direct Fastening Technology

Manual'.

Concrete spalling

Hard and/or large aggregates in

the concrete.

▶ Use the DX-Kwik method

(predrilling).

Damaged fastener head

Too much driving energy. ▶ Turn the selector ring for driving

energy to reduce driving energy.

The wrong piston has been fitted. ▶ Make sure that the correct

piston / fastener combination is

used.

The piston is damaged. ▶ Change the piston.

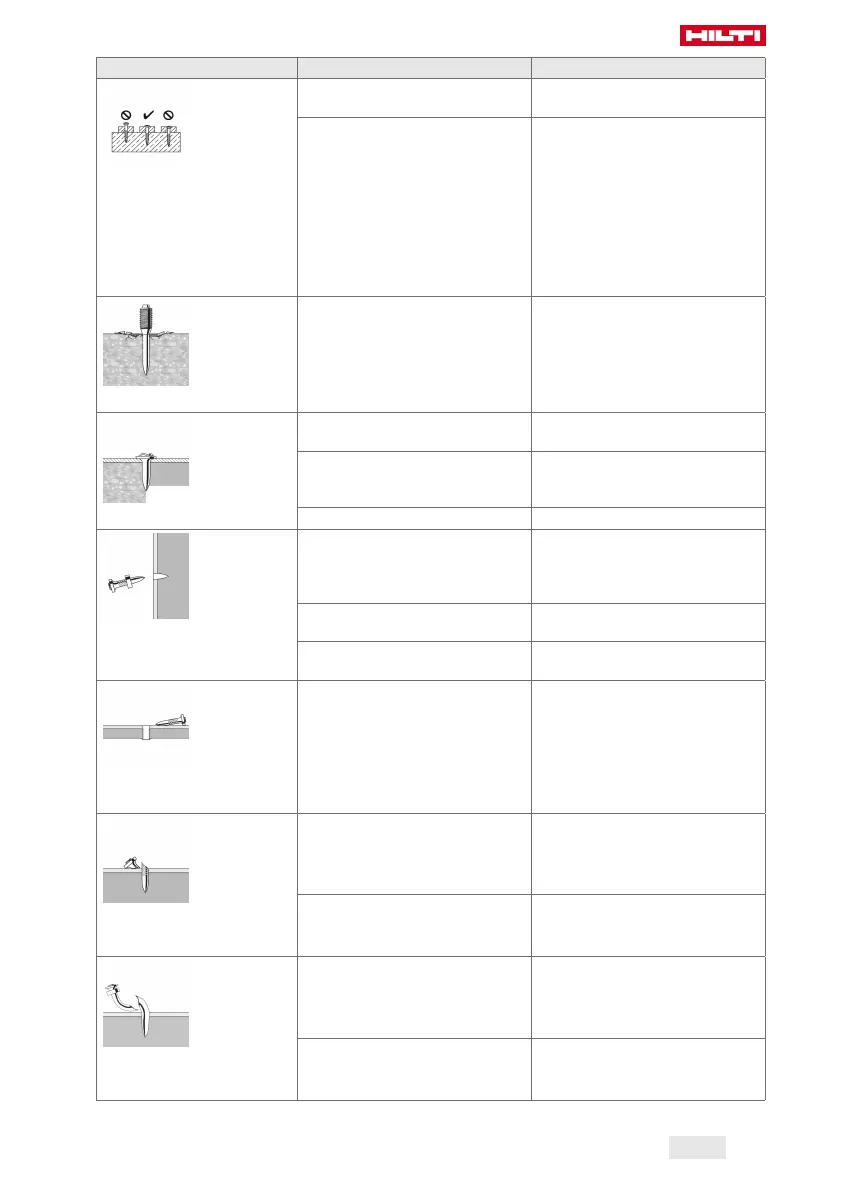

The nail doesn’t penetrate

deeply enough

Driving energy too low ▶ Turn the selector ring for driving

energy to increase driving

energy.

▶ Use an extra-strong cartridge.

The application limits have been

exceeded (very hard material).

▶ Use a nail with a higher

application limit.

The system is unsuitable. ▶ Use a more powerful system ,

e.g. DX 76 (PTR).

The fastener doesn’t hold in

the base material

Thin supporting steel (45 mm) ▶ Use a different energy setting.

▶ Use a nail suitable for thin

supporting steel.

Fastener breakage

(shear breakage)

Driving energy too low ▶ Turn the selector ring for driving

energy to increase driving

energy.

▶ Use an extra-strong cartridge.

The application limits have been

exceeded (very hard material).

▶ Use a more powerful system,

e.g. DX 76 (PTR), with corre-

sponding suitable fasteners.

Fastener breakage

(with deformation)

Driving energy too low ▶ Turn the selector ring for driving

energy to increase driving

energy.

▶ Use an extra-strong cartridge.

The application limits have been

exceeded (very hard material).

▶ Use a more powerful system,

e.g. DX 76 (PTR), with corre-

sponding suitable fasteners.

Loading...

Loading...