OM-923 Page 13

SECTION 4 − INSTALLATION

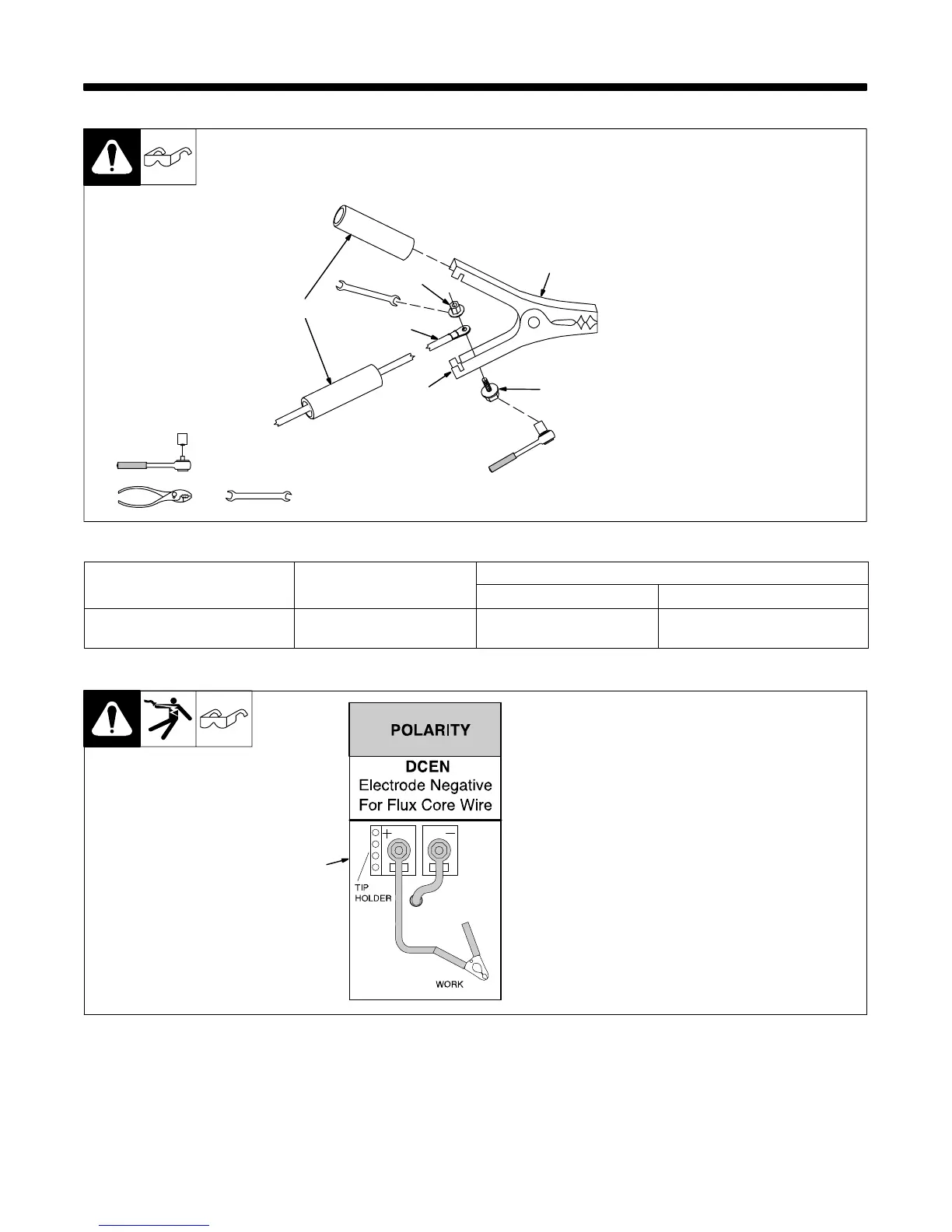

4-1. Installing Work Clamp

1 Nut

2 Work Cable From Unit

3 Work Clamp

4 Screw

5 Work Clamp Tabs

Bend tabs around work cable.

6 Insulator Grip

Slide one insulating grip over work

cable before connecting to clamp.

Slide insulating grips over handles.

Ref. 802 456

1

2

3

4

5

Tools Needed:

7/16 in

6

. Connection hardware must be tightened with proper tools. Do not just

hand tighten hardware. A loose electrical connection will cause poor

weld performance and excessive heating of the work clamp.

7/16 in

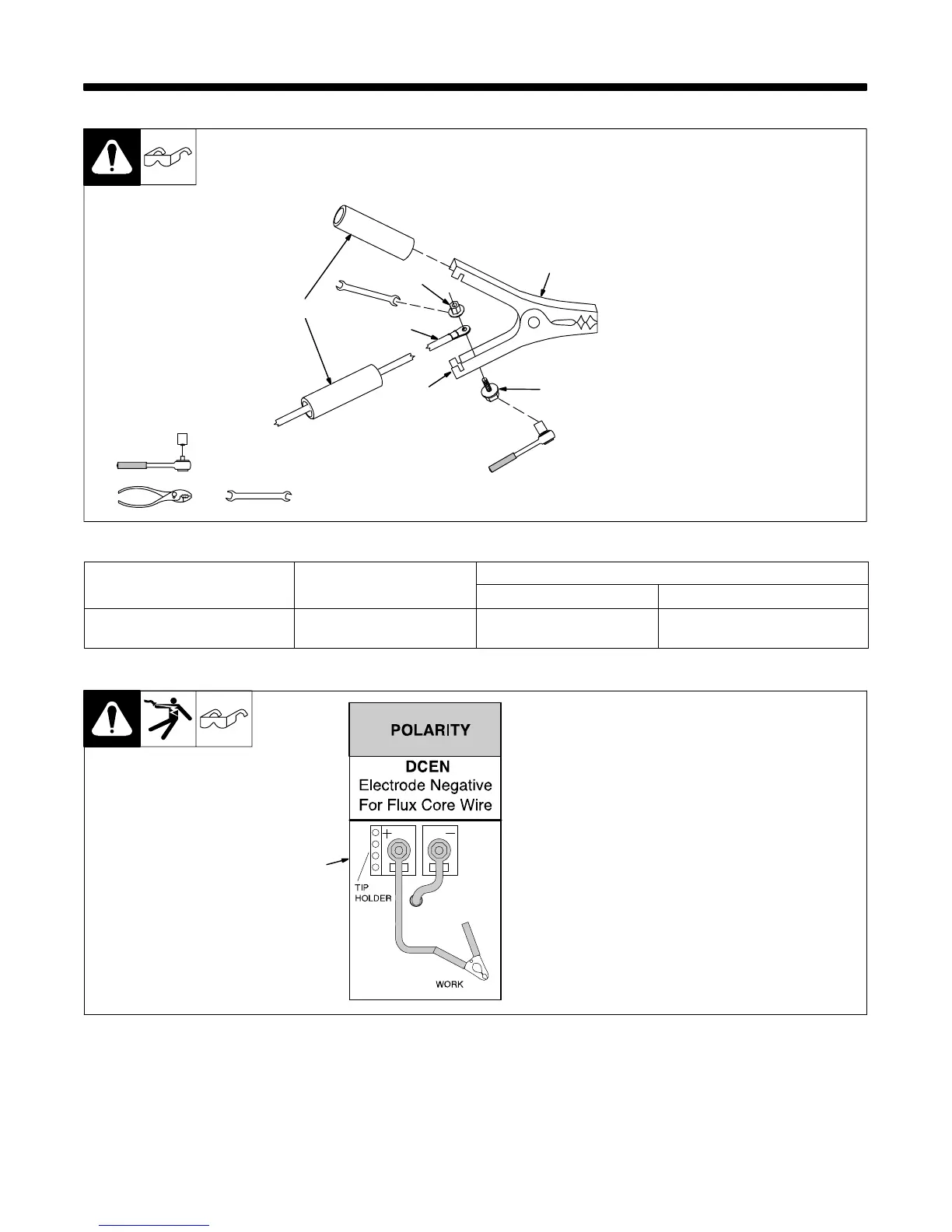

4-2. Process/Polarity Table

Process Polarity

Cable Connections

Cable To Gun Cable To Work Clamp

FCAW − Self-shielding wire −

no shielding gas

DCEN − Straight Polarity Connect to negative (−)

output terminal

Connect to positive (+) output

terminal

4-3. Polarity

. Polarity must be set for DCEN

(flux core wire) only.

1 Lead Connections For Direct

Current Electrode Negative

(DCEN)

Always read and follow wire

manufacturer’s recommended

polarity, and see Section 4-2.

Close door.

Ref. 210 428

1

Loading...

Loading...