TM-260 273 Page 26 Handler 190

SECTION 7 − MAINTENANCE

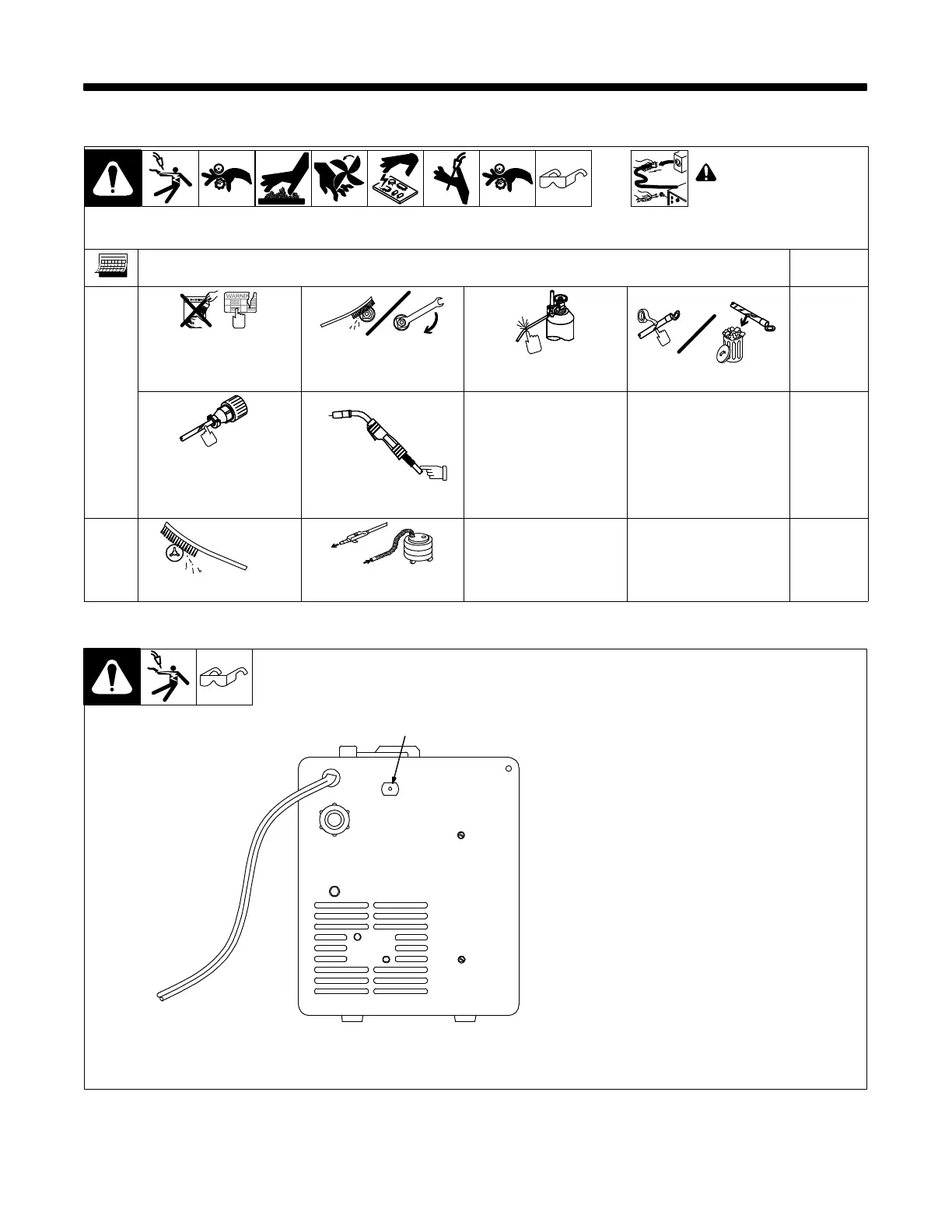

7-1. Routine Maintenance

! Disconnect power

before maintaining.

. Maintain more often

during severe conditions.

n = Check Z = Change ~ = Clean l = Replace

* To be done by Factory Authorized Service Agent

Reference

Every

3

Months

l Unreadable Labels ~ Weld Terminals l Damaged Gas Hose nl Weld Cables

nl Cords nl Gun Cables

Every

6

Months

OR

~ Drive Rolls ~ Inside Unit

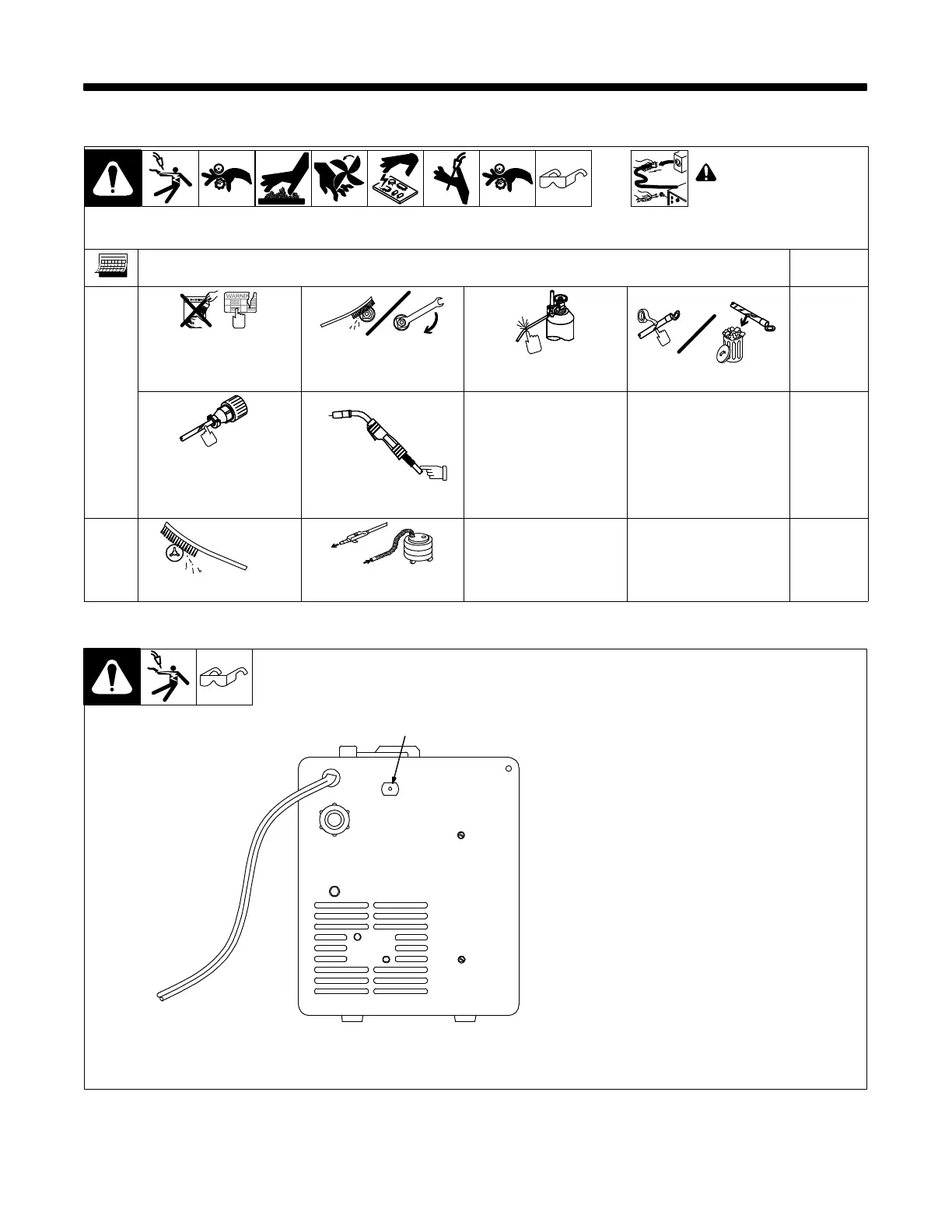

7-2. Overload Protection

802 441

1 Supplementary Protector CB1

CB1 protects unit from overload. If

CB1 opens, unit shuts down.

Reset supplementary protector.

1

7-3. Drive Motor Protection

Drive motor protection circuit protects drive motor from overload. If drive motor becomes inoperative, release gun

trigger and wait until protection circuit resets allowing drive motor to feed wire again.

Loading...

Loading...