Installation Guide and Operating Manual

Honeywell 16

SECTION 3: OPERATION

Figure 3.1 Principle of Operation

Honeywell Analytics’ multi-spectrum and multi-spectral infrared Fire and Flame Detectors are sophisticated,

state of the art, electro-optical digital radiant energy transducers that sense the wideband radiant energy emitted

by fire’s combustion processes that include flames’ molecular emissions and hot particulate blackbody

emissions. Radiant Energy Fire Detectors respond much faster to flames and fires at a longer distance than

other types of conventional photoelectric and ionization smoke and heat detectors because a fire’s emitted

radiant energy travels at the speed of light. Fast response is critical for detecting flaming fires in time to

successfully activate suppression or activate other fire responses such as closing fire doors. Seconds can make

the difference between suppressing a small fire with little or no damage or having a disastrous fire that

overwhelms a suppression system thereby failing to stop the fire.

Infrared (IR) consists of spectral wavelengths longer than the color red. The IR range for fire detection, which is

invisible to the human eye, is from about 700 nanometers to 7000 nanometers (0.7 to 7.0 microns). Honeywell

Analytics’ FS24X Fire Detectors utilize a NearBand IR™ portion of the spectrum from approximately 185 to 260

nanometers and a WideBand IR portion from approximately 0.7 to 3.3 microns. This allows the FS24X Detectors

to sense over 80% of the total radiant “Blackbody Energy” emitted by a fire. Honeywell Analytics’ Detectors

sense and measure the radiant energy generated by a fire at the speed of light.

FSX Detectors also utilize an additional spectral region, the Visible Band, that spans from about 400 to 700

nanometers (0.4 to 0.7 microns.) The Visible Band is used to further discriminate against non-fire false alarm

sources. The Model FS24X Detectors also sense the specific WideBand 4.3 IR™ “Triple IR”. Sensing these

hydrocarbon wavelengths does not inhibit the Detector’s ability to see non-hydrocarbon fires. Built-in

microprocessors use sophisticated Digital Signal Processing (DSP) to accurately distinguish radiant energy from

a real fire and a false alarm source(s). Honeywell Analytics has developed and refined these complex

proprietary and patented WideBand IR algorithms over the last 30 years. These patented algorithms perform

real-time DSP, and precisely analyze the signals in high-resolution frequency and time domains. This decision

making process involves thousands of real-time calculations every second. Honeywell Analytics FS24X

Detectors use solid-state high speed quantum sensors (not heat sensors such as pyroelectric or thermopile) that

all respond to the fire’s radiant energy emissions. The quantum sensors convert the rate of photonic energy

directly into analog electrical signals. These analog signals are then converted to high resolution digital bits for

real-time microprocessor analysis. The Detector microprocessors incorporate random access memory (RAM),

read-only memory (ROM), and non-volatile flash memory. When the microprocessors determine that a real fire

has been detected, the pre-alarm digital sensor data (FirePic™) and the event information are recorded in flash

memory. Depending on the configuration, other actions may include activating one or more status LEDs, relays,

a current loop and sending digital data such as the RS-485 FireBus

II, and Modbus. If the microprocessors

determine, based on internal testing and “through-the-lens” testing, that the Detector is not operating correctly, it

records the Fault data and activates the Fault outputs and the yellow status LED. The digital data in the

Detector can be easily accessed with a PC for later analysis and record keeping using Honeywell Analytics’

Windows

®

based PC software and FSIM-2 USB Interface Unit.

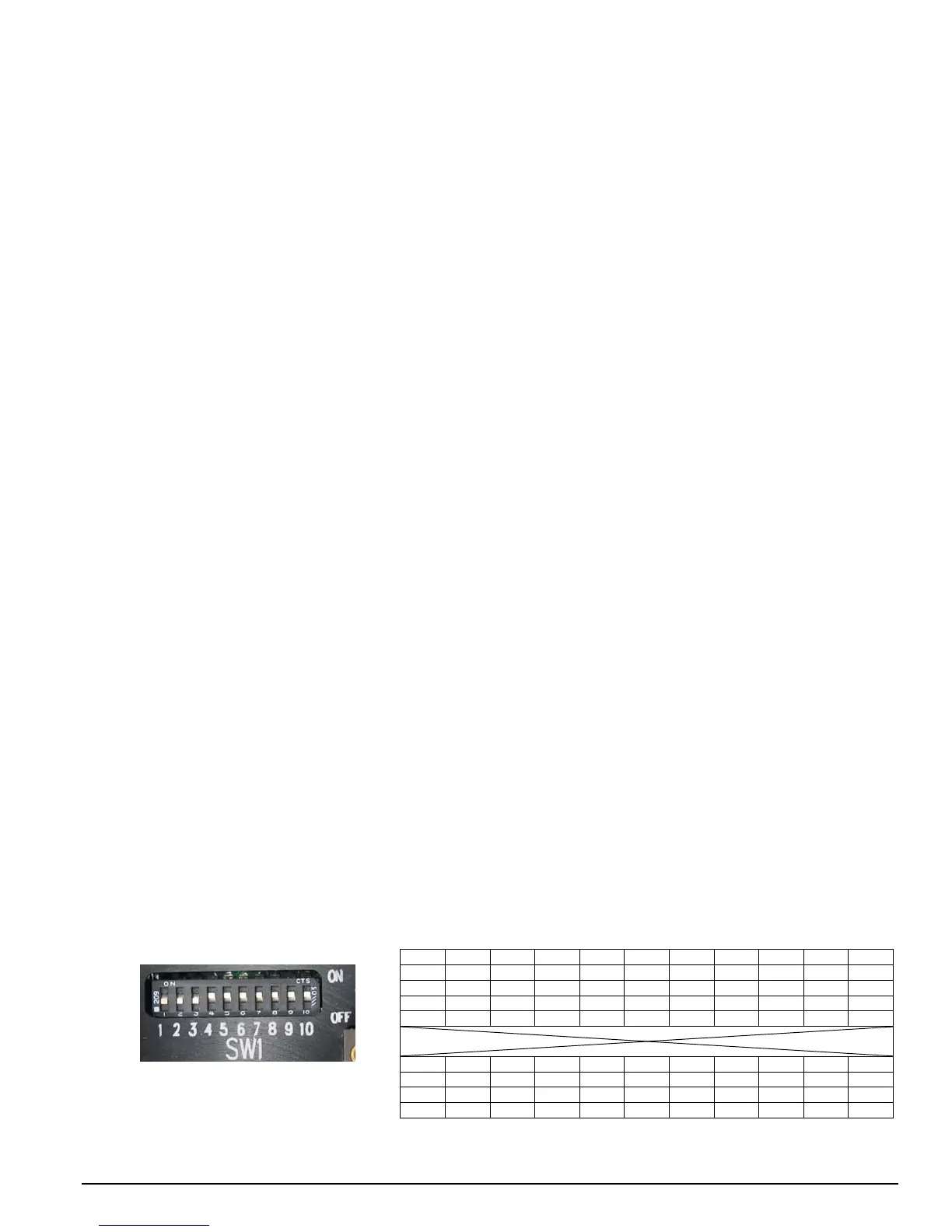

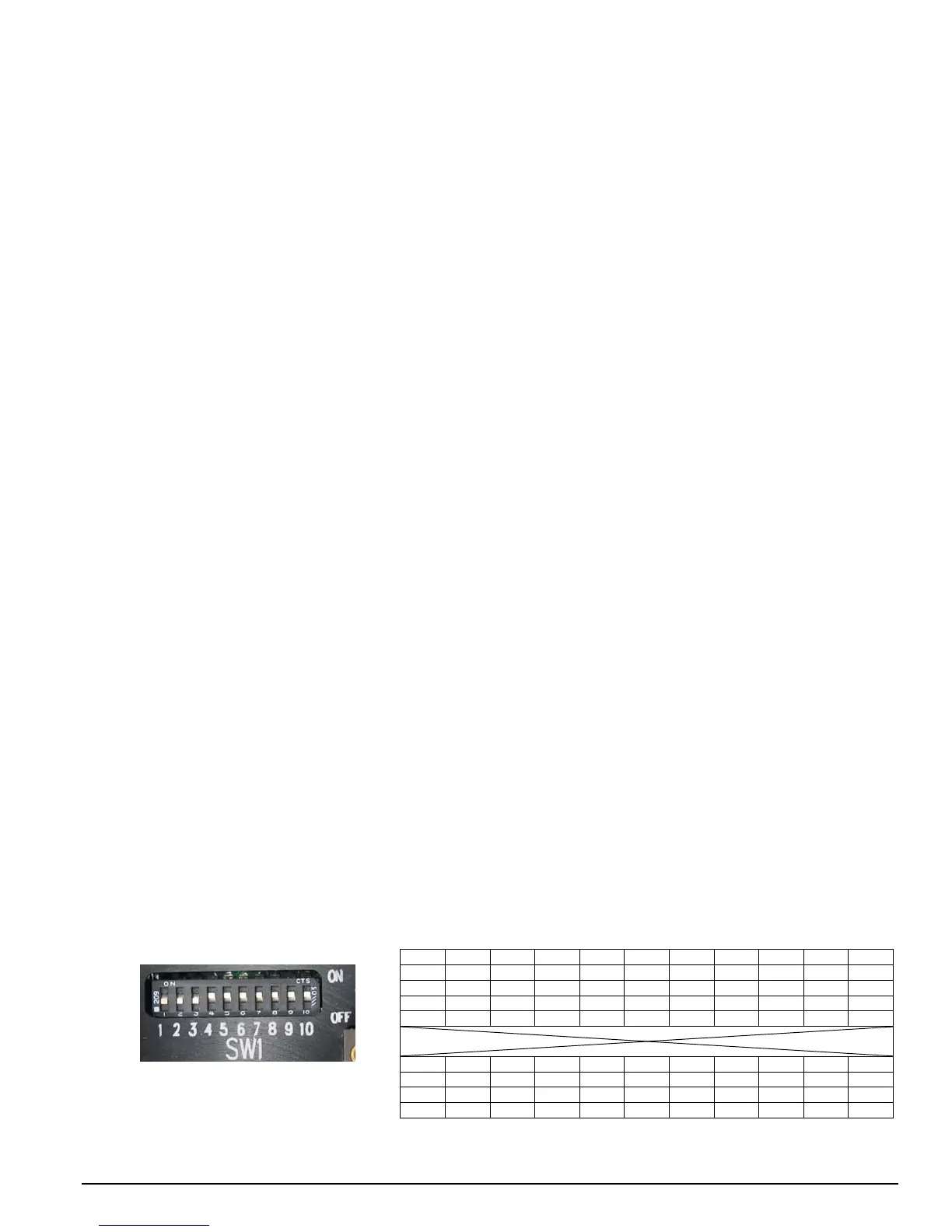

Figure 3.2 Configuring the Detector

IMPORTANT: Changing the Detector Settings – To activate changes to the settings using SW1, SW2 and

SW3, reset the Detector by removing and re-applying 24 VDC input power.

The Digital Address for the RS485 Communication can be set using positions 4 through 10 on SW1. Switch

positions 1, 2 & 3 for SW1 are for factory use only and should not be changed.

1 2 3 4 5 6 7 8 9 10

127

OFF OFF OFF ON ON ON ON ON ON ON

126

OFF OFF OFF ON ON ON ON ON ON OFF

125

OFF OFF OFF ON ON ON ON ON OFF ON

124

OFF OFF OFF ON ON ON ON ON OFF OFF

003

OFF OFF OFF OFF OFF OFF OFF OFF ON ON

Figure 3-1 (SW1)

Ten (10) Position DIP Switch

002

OFF OFF OFF OFF OFF OFF OFF OFF ON OFF

001

OFF OFF OFF OFF OFF OFF OFF OFF OFF ON

000

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

Loading...

Loading...