Transport and installation

HON 380 gas pressure regulator with HON 673/674 controller 31

5.4 Checking the system for leaks

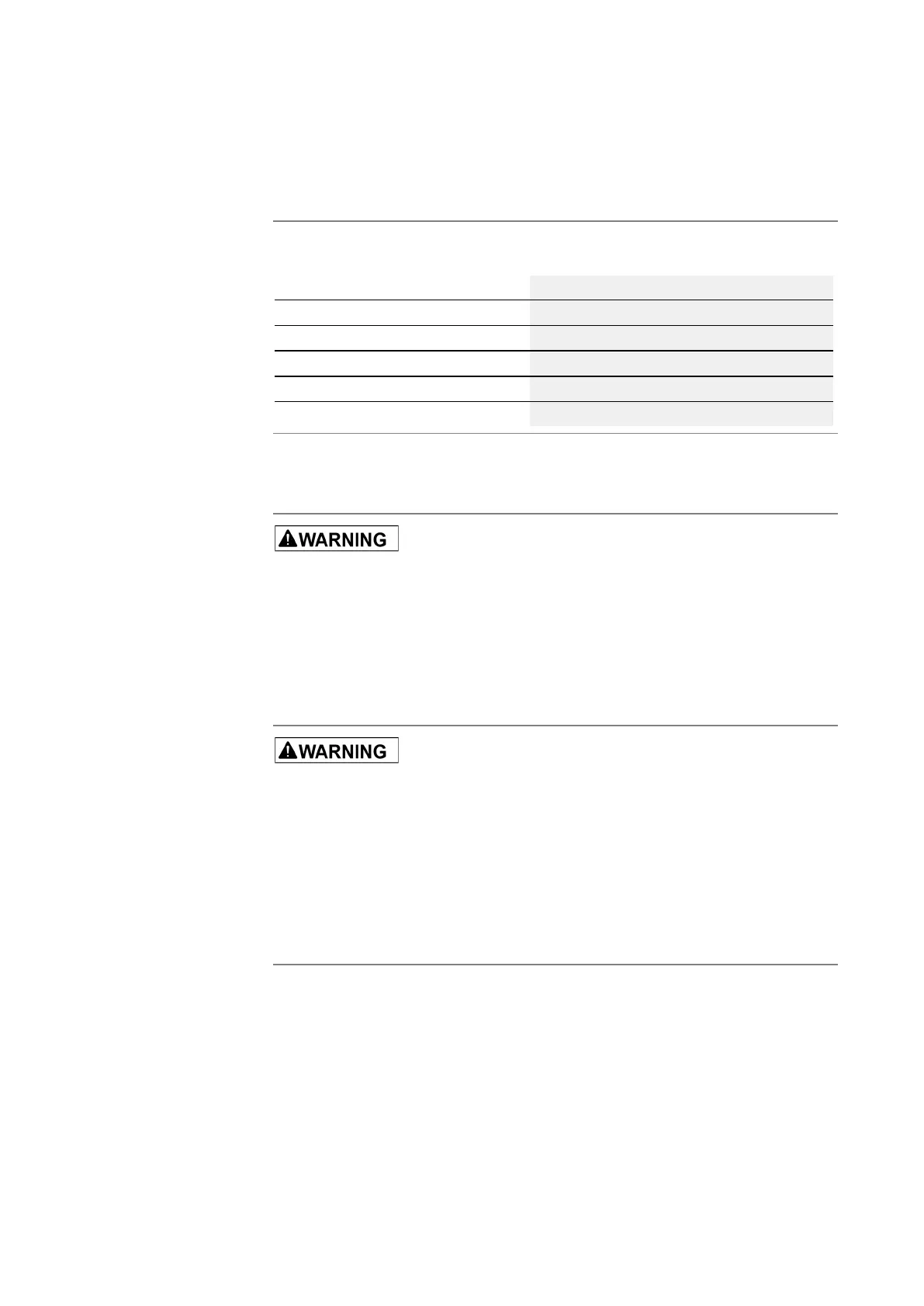

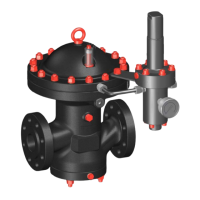

Prior to delivery, the manufacturer conducted a pressure and leak test on the gas

pressure regulator as specified in DIN EN 334.

The gas pressure regulator installed in the system must be subjected to a leak test

at the setup location as follows:

Normative basis DVGW Technical Rule G 491

Test method Bubble test method

Test medium Air or inert gas

Scope of the test All detachable pipe joints

Test equipment Foam-generating leakage medium

Test pressure 1.1 times the operating pressure (MOP)

The device installed into the system must undergo a leak test at the set-up loca-

tion in accordance with applicable international and national standards.

Risk of serious injury posed by pressurized components moving in an uncon-

trolled manner when handled improperly.

If not handled properly or in the event of a defect, gas can escape from pressur-

ized components under high pressure and cause serious injuries and even death.

Before you start working on these components:

Close all connections leading to the gas-carrying line.

Establish a depressurized status. Residual amounts of energy must be depres-

surized as well.

Risk of injury posed by bursting parts in the event that they are subjected to

pressure in the wrong direction

The device has been designed for a specific direction of flow, which is labeled on

the device. Subjecting the device to pressure in the wrong direction may result in

serious injury caused by bursting parts.

Pressurize the system only on the inlet side.

Details about the operating pressure can be found in the technical specifications.

Technical specifications

by the manufacturer

Leak test at the set-up

location (in Germany)

location (in other

countries)

Loading...

Loading...