T775R SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

9 62-0249—13

CHECKOUT

Inspect all wiring connections at the controller terminals,

and verify compliance with the installation wiring

diagrams.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring

or making wiring connections, to prevent electrical

shock or equipment damage.

If any wiring changes are required, first be sure to remove

power from the controller before starting work. Pay

particular attention to verifying the power connection

(24, 120, or 240 Vac).

After the controller is mounted and wired, apply power.

Power Loss

The date and time settings are retained for 24 hours after

a power outage. After a power loss of more than 24 hours,

the date and time settings may need to be reentered. All

other settings are stored permanently.

Temperature Sensor Calibration

As wire length increases, resistance increases and thus

the temperature reading increases. If necessary, calibrate

the sensor input by reducing the value by the amount

shown in the Tables 3 and 4. For example, a wire run with

18 gauge wire of 1,000 feet, requires a calibration offset of

-6.0°F (-21° C).

IMPORTANT

If the calibration value in the table exceeds the

controller’s calibration limits of +/-10° F (+/-6° C),

you must use a heavier gauge wire. For

example, with a wire run of 1,000 feet you must

use 20 AWG wire or heavier in order to calibrate

for wire loss within the limits of the controller.

Refer to “3.2.2.2. CALIBRATE (the sensor)” on page 20

for the instructions to enter the calibration value.

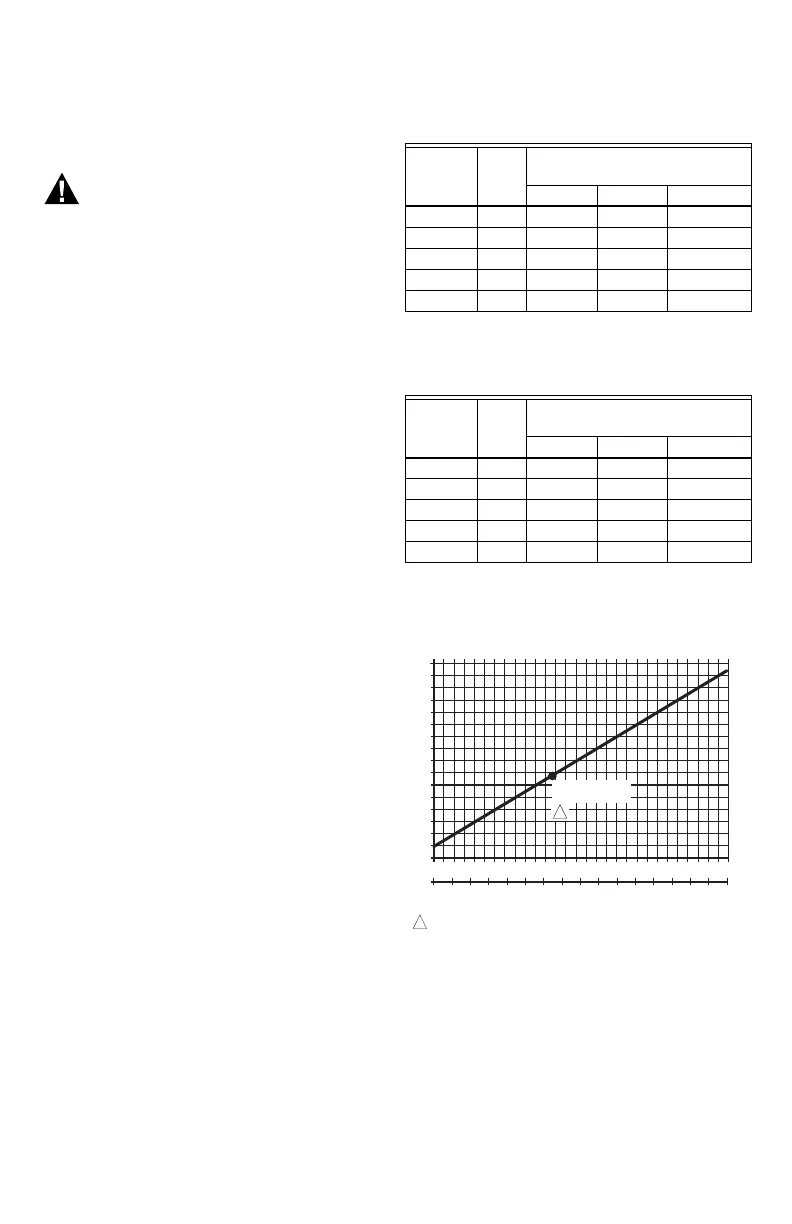

Table 3. Temperature Sensor Calibration for Resis-

tance Loss due to Wire Length (Feet).

a

This is the distance from the controller to the sensor

(already accounts for round trip distance).

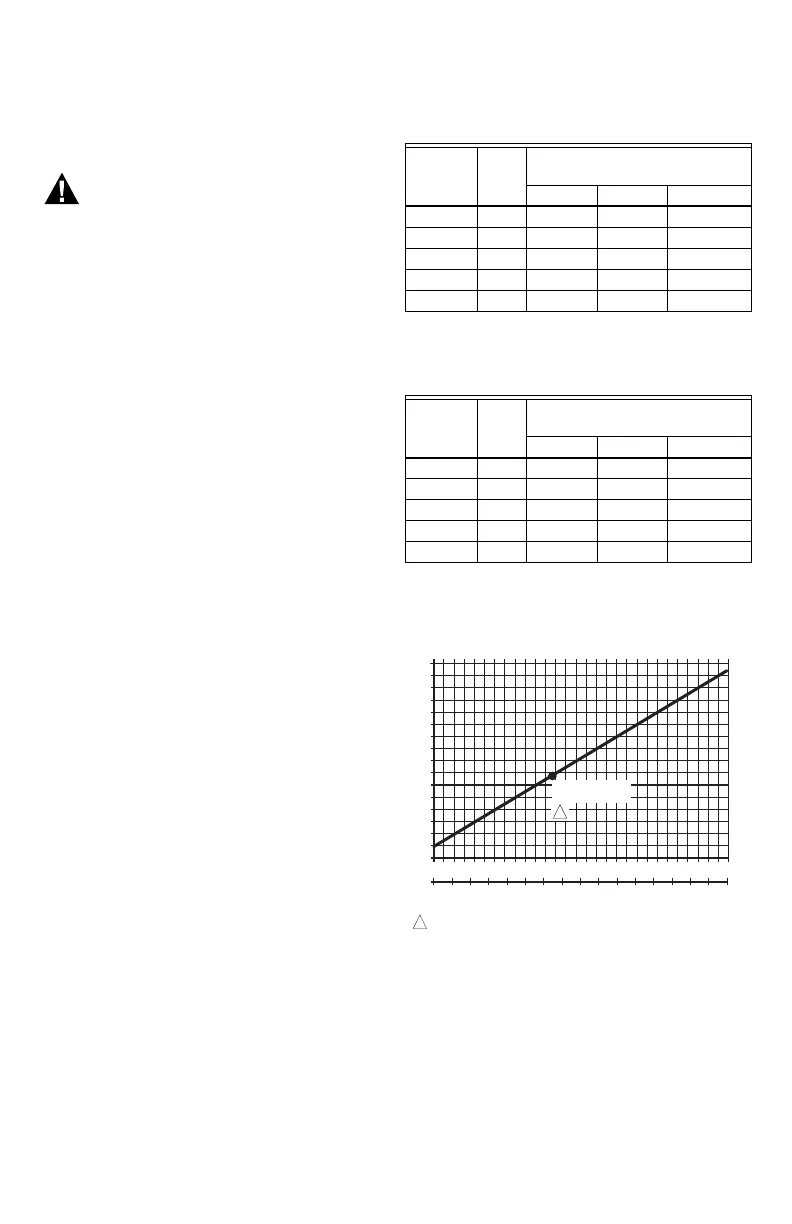

Table 4. Temperature Sensor Calibration for Resis-

tance Loss due to Wire Length (Meters).

Fig. 19 shows how sensor resistance varies with

temperature for a sensor having a positive temperature

coefficient (PTC) of 2.1 Ohms per degree F (3.85 Ohms

per degree C).

Fig. 19. Sensor Resistance vs. Temperature.

AWG

Rating mΩ/ft

Temperature Offset in

° F (Foot)

a

200 ft 500 ft 1,000 ft

14 2.5 0.46 1.14 2.28

16 4.0 0.72 1.82 3.64

18 6.4 1.16 2.90 5.82

20 10.2 1.86 4.64 9.28

22 16.1 2.92 7.32 14.64

AWG

Rating mΩ/ft

Temperature Offset in

° C (Meter)

a

100 m 200 m 300 m

14 8.3 0.44 0.86 1.30

16 13.2 0.68 1.38 2.06

18 21.0 1.10 2.18 3.28

20 33.5 1.74 3.48 5.22

22 52.8 2.74 5.48 8.22

M24304

TEMPERATURE (DEGREES)

RESISTANCE (OHMS)

1403

1317

1231

1145

1059

973

20 40 60 80 100 120 140 160 180 200 220

0 10 20 30 40 50 60 70 80 90 100

°F

°C

0-20-40

120

110

250

-40 -20 -10-30

1489

887

801

1097 ± 0.08 OHMS

AT 77°F (25°C)

POSITIVE TEMPERATURE COEFFICIENT (PTC) OF 2.1 OHMS PER °F

1

1

Loading...

Loading...