Calibration Handbook

55Manning EC-F2

EC-F2 Calibration Procedure

General Information

The Manning EC-F2 sensor should be calibrated a minimum of once every six months, or after exposure to a

large concentration of gas. The Manning EC-F2 sensor generally becomes less sensitive with age, therefore

regular calibration is critical to maintain the accuracy of the sensor.

Zero Calibration

After the unit is installed and has been powered up for a minimum of 24 hours, the unit should be zero calibrated

by the following two procedures.

NOTE: If the sensor output is erratic immediately after the installation of a new cell, it may be a high gain

(span) setting left over from a previous cell that was adjusted for aging.

s Be sure the unit is in clean air, or apply zero air at 1.0 L/min.

s Adjust the zero pot until the sensor outputs 4.0 mA (40 mV from Test [—] to Test [+]).

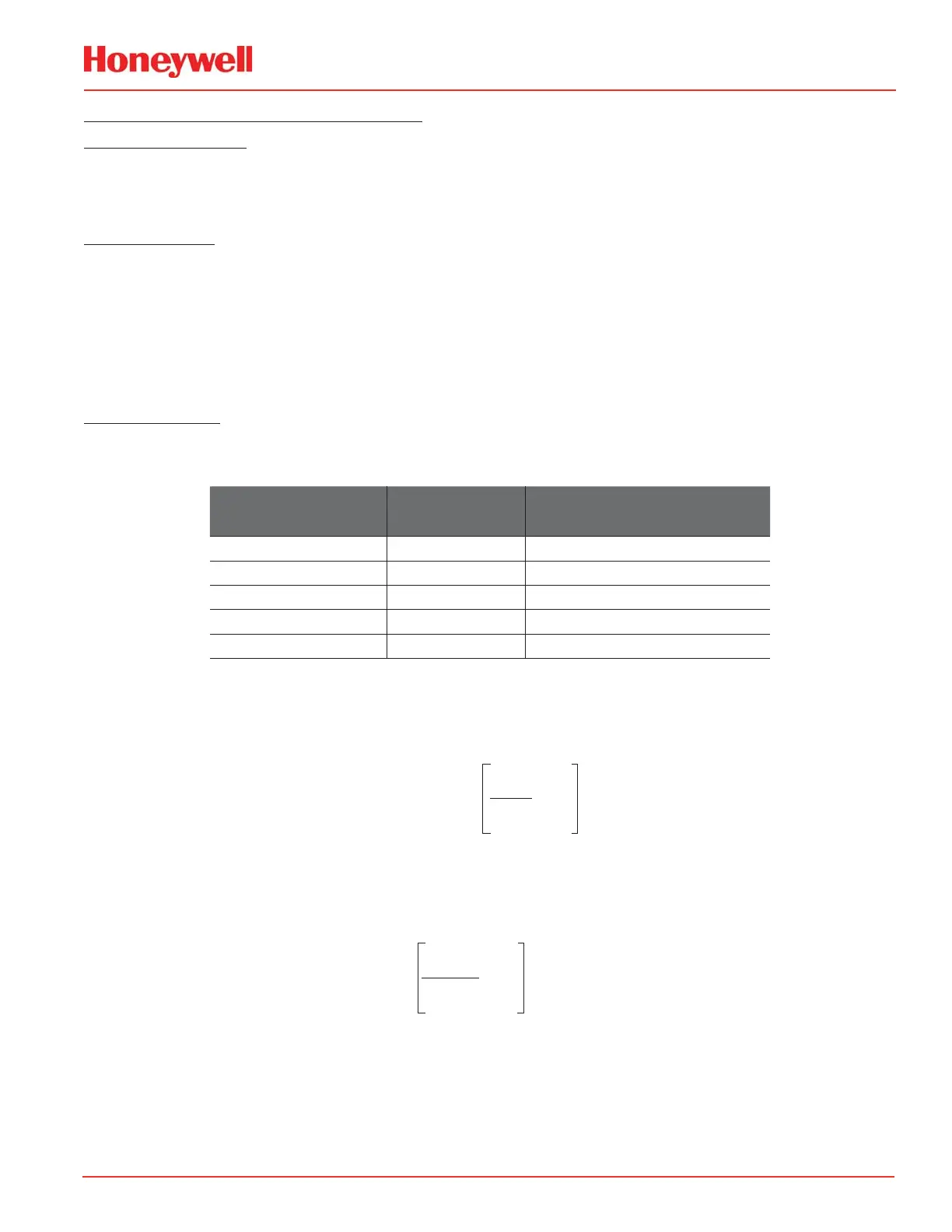

Span Calibration

s Perform zero adjustment before spanning.

s The table below shows what span gas to use and what the signal should be for various sensor ranges:

Sensor Range

(ppm)

Span Gas

(ppm)

Calibrated Signal Voltage

(mV)

0—100 100 200

0—250 100 104

0—250 250 200

0—500 250 120

0—1,000 1,000 200

s Place calibration adapter firmly over the sensor.

s Apply span gas at 1.0 L/min (span gas must be in air, not nitrogen or other carrier).

s After span gas has been on sensor for two minutes, adjust the span pot until the correct output is achieved.

For combinations not shown in the previous table, use the following formula to determine the output:

SGC

Signal (mA) = x 16 + 4

SFSV

Where:

SGC = Span Gas Concentration,

SFSV = Sensor Full Scale Value.

For example if 100 ppm SGC gas is used to calibrate a 250 ppm SFSV sensor, the signal would be as follows:

100ppm

Signal = x 16 + 4 = 10.4 mA

250ppm

10.4 mA = 104 mV from TEST (—) to TEST (+)

If the correct output cannot be achieved, a replacement cell is required.

Loading...

Loading...