Calibration Handbook

115Series 3000 XPIS

Series 3000 XPIS Calibration Procedure

The following equipment is required:

s Appropriate span gas cylinder

s Flow regulator set to 300-375mL/min

s Tubing

s Magnet

s Calibration gas flow housing

NOTE

gas. If no residual gas is present then background air can be used to perform zero.

Zero and Span Calibration

CAUTION

Before initial calibration allow the detector to stabilize for 30 minutes after applying power. When in zeroing

and span calibration mode the current output from the detector is inhibited (default 3mA) to avoid false alarms.

It is recommended for most sticky gases the tubing should be PTFE with short pieces of rubber tube to make

allows for more accurate measurement.

NOTE

is to be used. Re-calibration is recommended if the temperature of local environment has varied by more

It is essential that the sensor is tested frequently to be sure the system is operating properly. Typically gas

environmental conditions and in the presence of other gases. It is the responsibility of the user to determine

an appropriate calibration frequency for the application.

1. If using compressed air, push the calibration gas flow housing onto the bottom of the sensor and apply

the gas.

2. To access the calibration mode, hold the end of the magnet over the switch located at the top centre of

the detector display for at least 5 seconds and then remove.

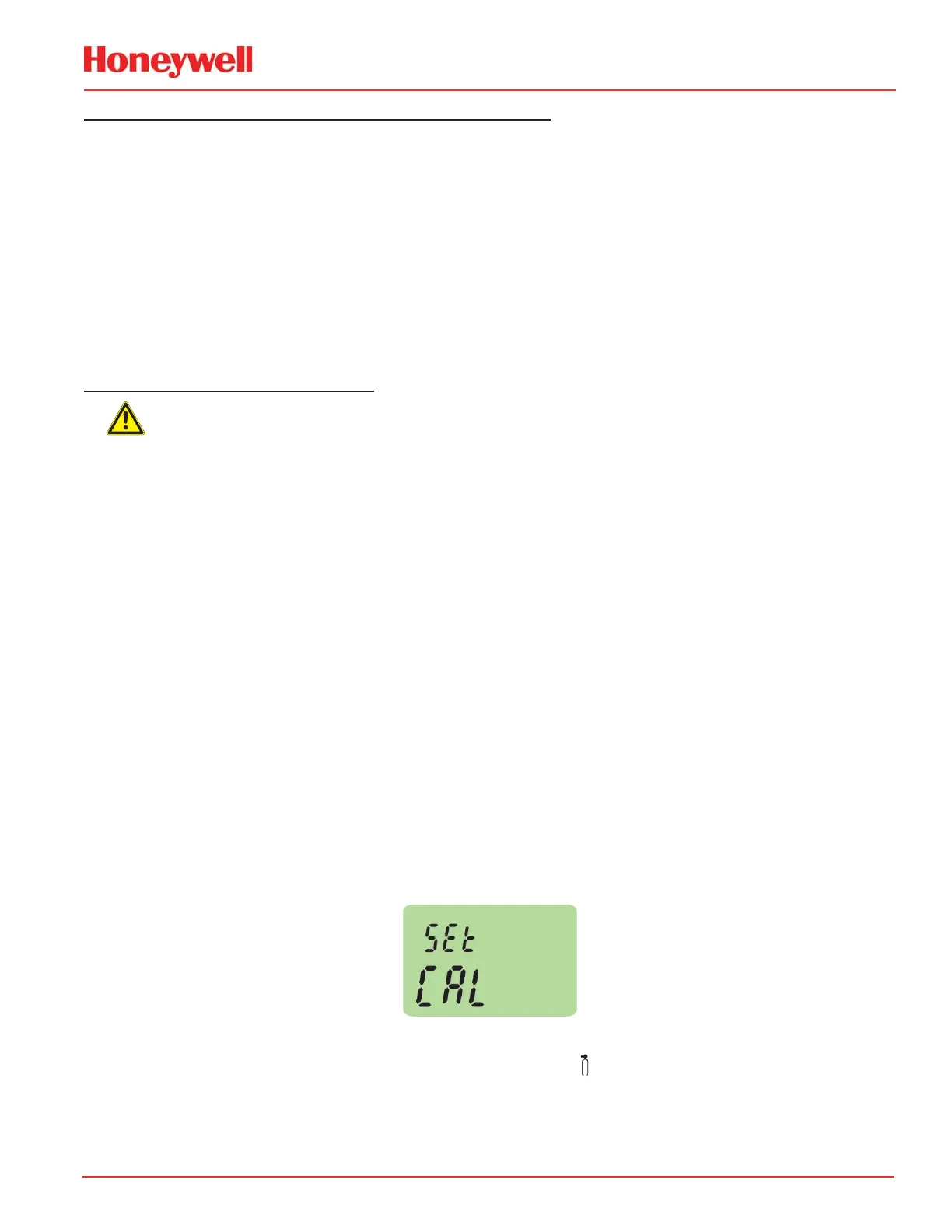

3. The display will indicate the first menu mode menu ‘SEt CAL’.

4. Place magnet over the ‘✓’ switch and remove to enter the Calibration menu.

5. The display will show the current gas reading, ‘ZEro’ and the ‘

’ icon flashes.

Loading...

Loading...