Calibration Handbook

121Sensepoint Toxic

Sensepoint Toxic Calibration Procedure

The Sensepoint toxic sensor is supplied pre-calibrated, however, for increased accuracy in specific applications,

on-site system calibration is recommended.

CAUTION

Calibration should only be attempted after the sensor has been installed and power applied for a time exceeding

the stabilization time. In the first instance the initial calibration should be performed at the control card for the

sensor. If there is insufficient span or zero control at the control card, adjustments can be performed using

the potentiometers on the sensor.

1. Ensure that power is applied to the sensor and the sensor output is stable.

2. First ensure there is no target gas present, and zero the sensor at the control card. If the target or a cross

interfering gas is suspected to be in the vicinity of Sensepoint, it may be necessary to connect a cylinder

of zero gas to a Flow Housing and pass clean air across the sensor at 1 litre per minute to allow for a

stable zero to be achieved.

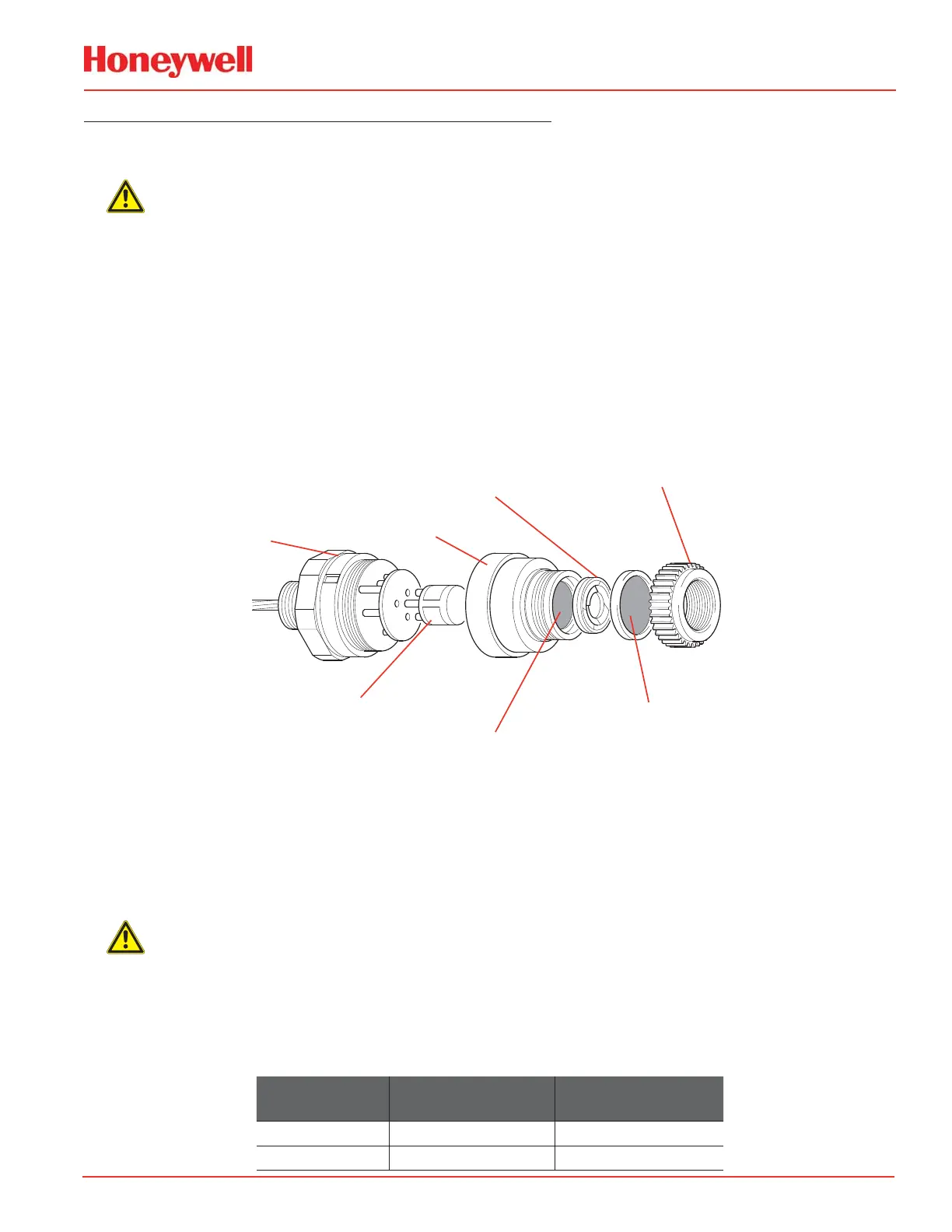

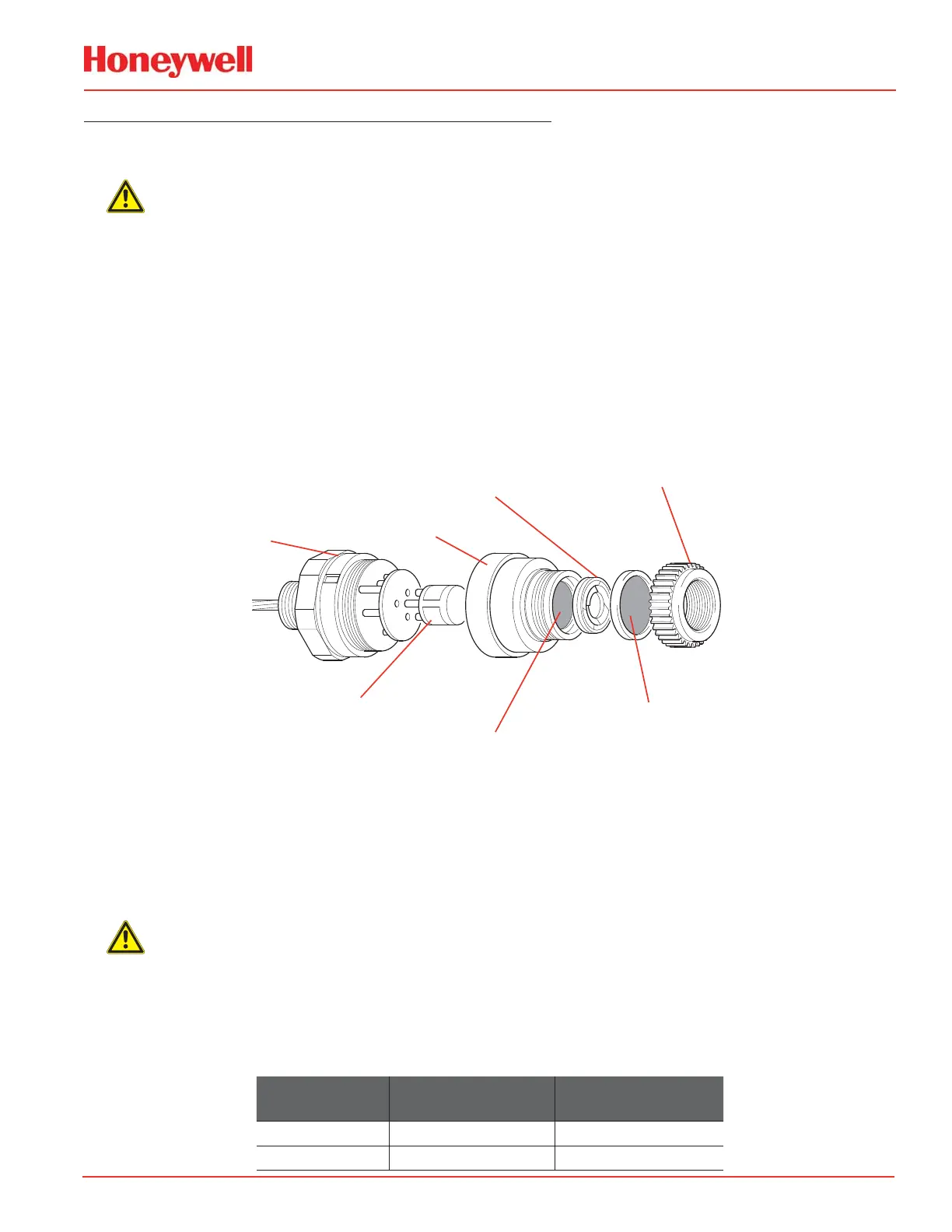

Main Sensor

Body

Sensor Cap

Internal

Hydrophobic Assembly

Filter

Housing/Retainer

RFI Screen/Metal Gauze

Electrochemical Cell

External

Hydrophobic Barrier

3. To set the sensor span, fit the Flow Housing and connect a gas cylinder of known concentration

(approximately 50% FSD in air) to the Flow Housing accessory using nylon or PTFE tubing.

Tubing lengths should be kept to a minimum to avoid reducing speed of response.

NOTE:

needed to obtain the necessary readings.

CAUTION

The test gas may be hazardous, it is important that the outlet of the Flow Housing is exhausted to a safe area.

4. Apply the gas at a flow rate of 1 liter per minute for the recommended application time (see Test Gas

Concentrations table below).

The flow rate for calibration in fast air flows must be adjusted as follows:

Wind Speed

(mph)

Measured Speed

Using Pitot (m/s)

Test Gas Flow Rate

(L/min) Series 2000

0 0.0 1.0

5 2.2 1.0

Loading...

Loading...