CHAPTER 12: DESCRIPTION OF PARAMETER SETTINGS

129 63-4528—04

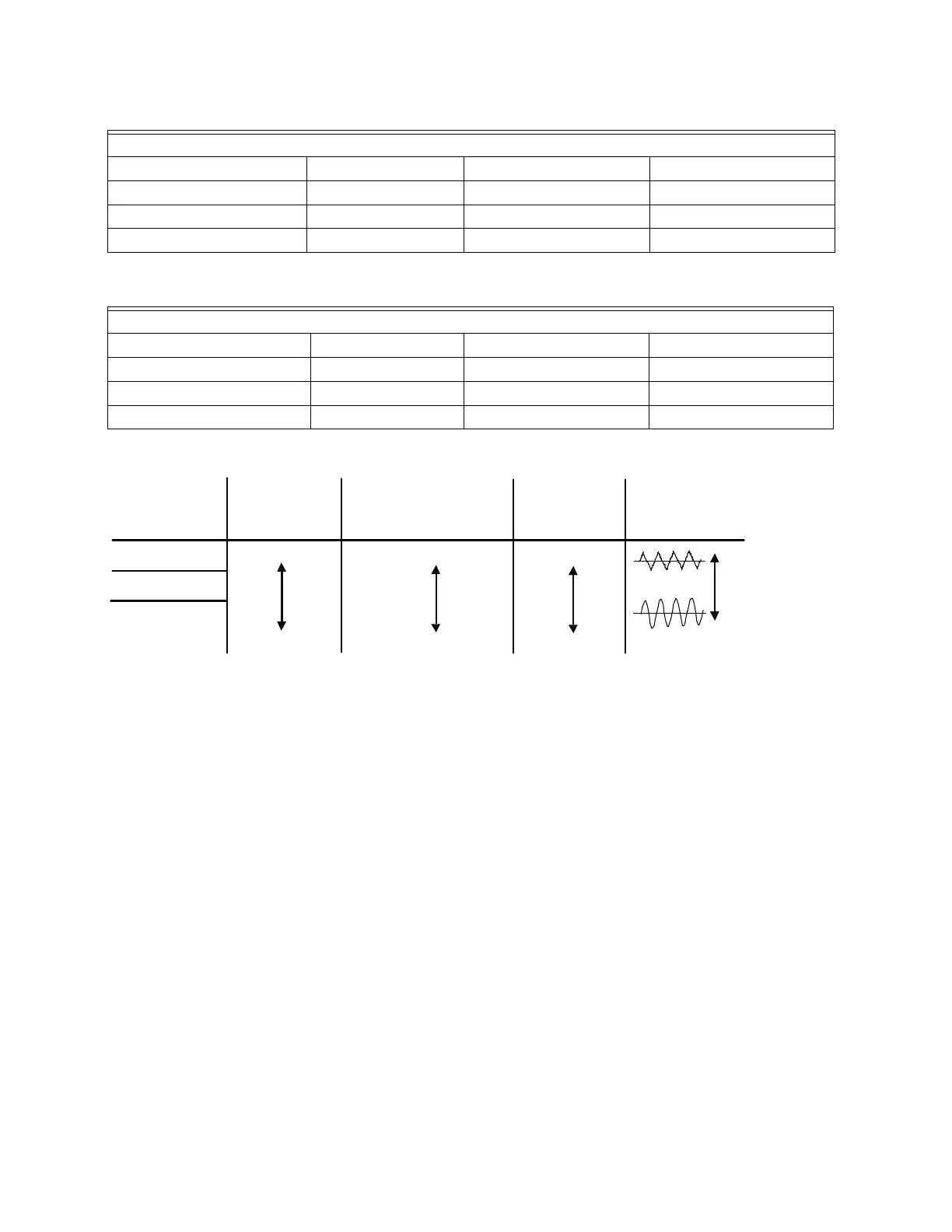

• From the table, we see that the PWM carrier frequency has a significant influence on the electromagnetic noise, VFD heat

dissipation, and motor acoustic noise. Therefore, if the surrounding noise is greater than the motor noise, lower the carrier

frequency is good to reduce the temperature rise. Although it is quiet operation in the higher carrier frequency, the entire wiring

and interference resistance should be considered.

• When the carrier frequency is higher than the factory setting, it needs to protect by decreasing the carrier frequency. See

Pr.06-46 for the related setting and details.

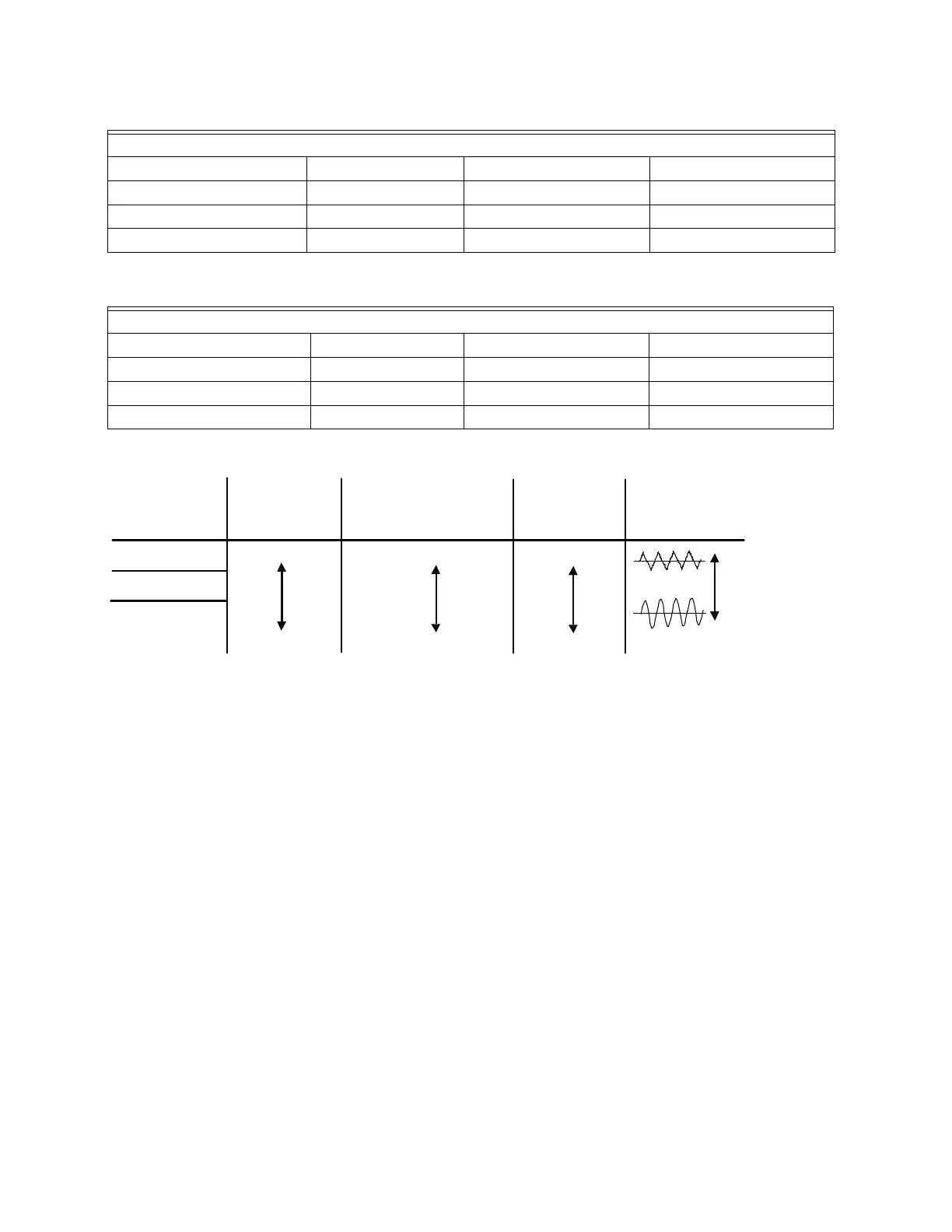

230V series

Models 1-20HP [0.75-15kW] 25-60HP [18.5-45kW] 75-125HP [55-90kW]

Settings 02~15kHz 02~10kHz 02~09kHz

Normal Duty Factory Setting 8kHz 6kHz 4kHz

Heavy Duty Factory Setting 8 kHz 6 kHz 4 kHz

460V series

Models 1-25HP [0.75-18.5kW] 30-100HP [22-75kW] 125-536HP [90-400kW]

Settings 02~15kHz 02~10kHz 02~09kHz

Normal Duty Factory Setting 2kHz 2kHz 2kHz

Heavy Duty Factory Setting 8 kHz 6 kHz 4 kHz

00 - 13 PLC Command Mask

Factory Setting: Read Only

Settings Bit 0: Control command controls by PLC

Bit 1: Frequency command controls by PLC

Bit 2: Reserved

Bit 3: Reserved

a

00 - 14 Source of the MASTER Frequency Command (AUTO)

Factory Setting: 0

Settings 0: Digital keypad

1: RS-485 serial communication

1kHz

8kHz

15kHz

Carrier

Frequency

Acoustic

Noise

Noise or Leakage

Current

Heat

Dissipation

Current

Wave

Significant

Minimal

Minimal

Minimal

Significant

Significant

Loading...

Loading...