CHAPTER 12: DESCRIPTION OF PARAMETER SETTINGS

63-4528—04 208

controlled by the P action only, and sometimes, if the integral component is functioning, the whole system will be vibrating. On

such occasions, in order to make the P action’s vibration subsiding and the system stabilizing, the PD control could be utilized.

In other words, this control is good for use with loadings of no brake functions over the processes.

• PID Control: Utilize the I action to eliminate the deviation and the D action to restrain the vibration, thereafter, combine with the

P action to construct the PID control. Use of the PID method could obtain a control process with no deviations, high accuracies

and a stable system.

Serial Connection

Parallel connection

• This parameter is only valid when the feedback signal is ACI.

a

08 - 07 Feedback Signal Detection Time

Factory Setting: 0.0

Settings 0.0~3600.0 seconds

M33691

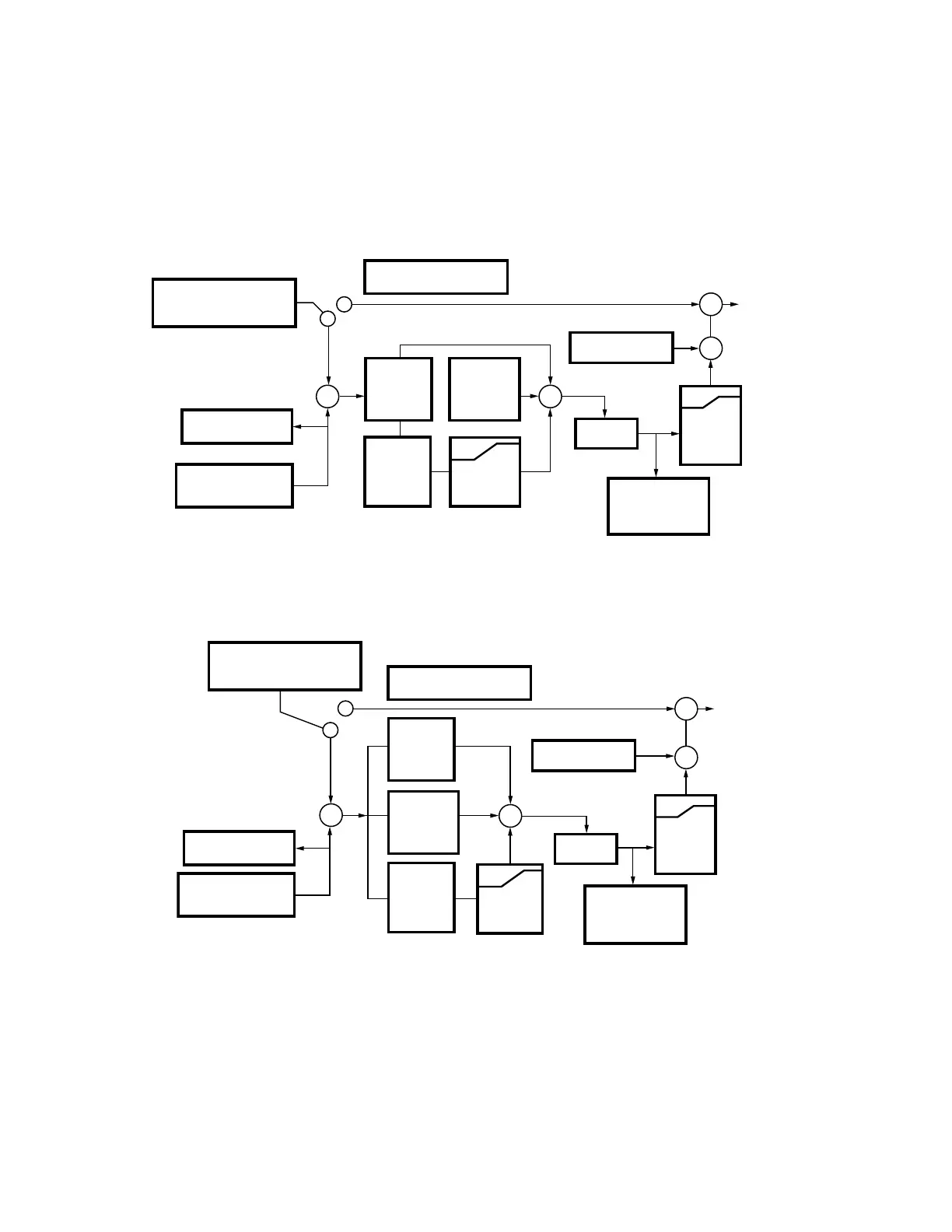

INPUT SELECTION OF THE

PID TARGETED VALUE

00-14:KPC-CC01/RS485

03-00 ~ 02: UP/DOWN KEY PG

DISPLAY OF THE PID

FEEDBACK 00-04 10

INPUT SELECTION OF

THE PID FEEDBACK

08-00:AVI/ACI AUI/PG

PID CANCELLED 08-00 0 OR

02-01~ 06 21 (PID OFF)

FREQUENCY

COMMAND

PID COMPENSATION

08-16

PID DELAY

TIME 08-06

08-05

PID FREQ.

OUTPUT

COMMAND

LIMIT

08-08 TREATMENT

OF THE FEEDBACK

SIGNAL FAULT IF

Hz>08-05 TIME

EXCEEDS 08-08

PROPORTION

GAIN 08-01

DIFFERENTIAL

TIME 08-03

08-02

INTEGRAL

TIME

08-04

UPPER

LIMIT FOR

INTEGRAL

+

++

P

D

I

2

1

+

+

+

M33692

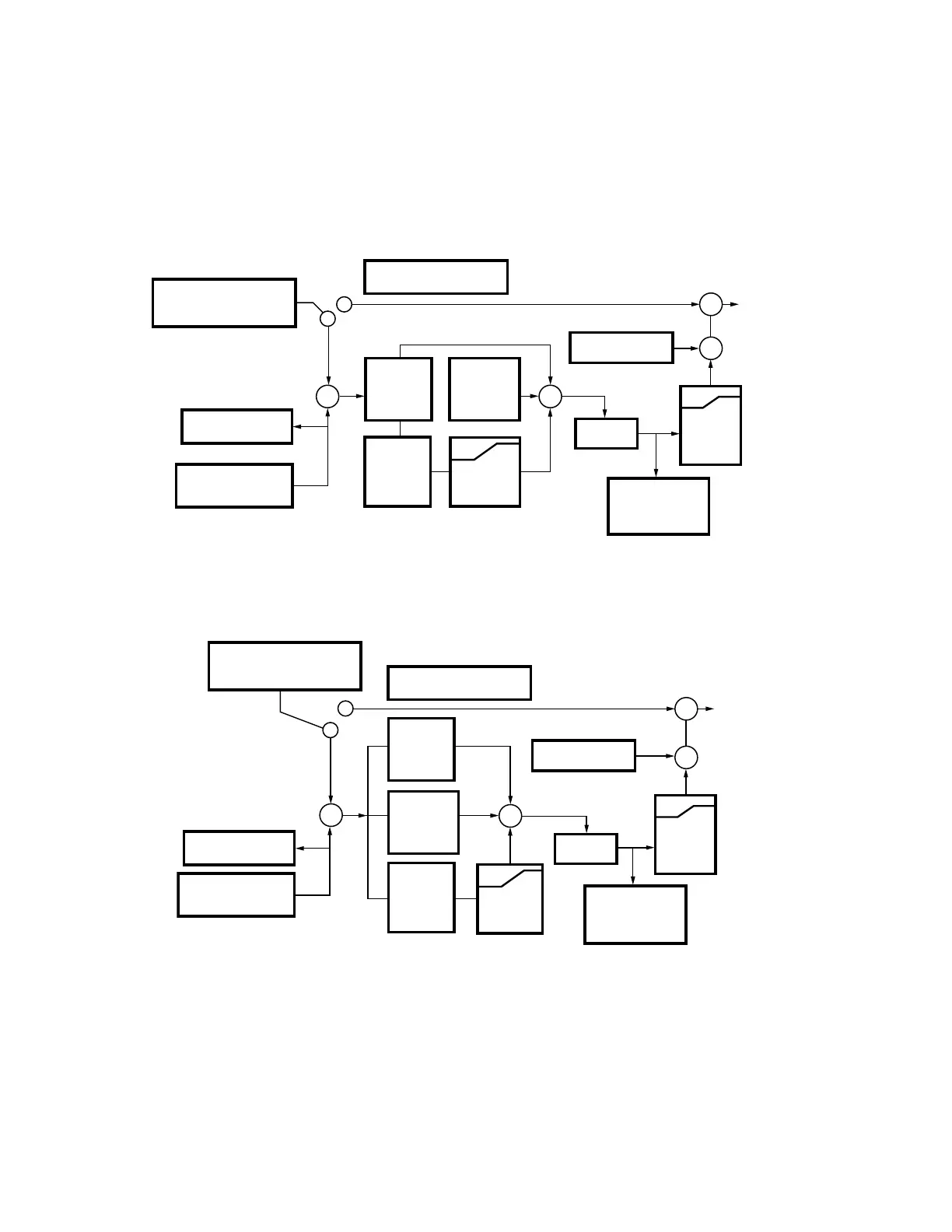

INPUT SELECTION OF THE

PID TARGETED VALUE

00–14:KPC-CC01/RS485

03–00 ~ 02: UP/DOWN KEY PG

DISPLAY OF THE PID

FEEDBACK 00–04 10

INPUT SELECTION OF

THE PID FEEDBACK

08–00:AVI/ACI AUI/PG

PID CANCELLED 08–00 0 OR

02–01~ 06 21 (PID OFF)

FREQUENCY

COMMAND

PID COMPENSATION

08–16

PID DELAY

TIME 08–06

08–05

PID FREQ.

OUTPUT

COMMAND

LIMIT

08-08 TREATMENT

OF THE FEEDBACK

SIGNAL FAULT IF

Hz > 08–05 TIME

EXCEEDS 08-07

+

+

PROPORTION

GAIN 08–01

P

DIFFERENTIAL

TIME 08–03

D

08–02

INTEGRAL

TIME

I

2

1

08–04

UPPER

LIMIT FOR

INTEGRAL

Loading...

Loading...