4 Assembly

Rotary actuators 135 • M140 • M150 • M180

12 Version 2.0 - June 2012 Operating instructions

4.3 Mount rotary actuator on flap

If rotary actuator and flap are supplied as separate deliveries you will have to

mount the rotary actuator on the flap.

How to assemble a rotary actuator

1 Secure the coupling (6) to the actuator shaft with pins using the spiral pin (351)

2 Attach the knee (1) below the actuator with the four hexagon screws (426), using

spanner width 10 and thrust washers (306) applying a torque of 5 Nm.

3 Turn the hand lever (55) into the coupling (6).

4 Put the actuator with add-on kit on the flap.

5 Insert the four hexagon nuts (448) in the slots of the knee (1).

6 Insert the hexagon screws (428) spanner width 13 and slipped on thrust washers

(308)

from

below through the flap flange.

7 Connect the four hexagon screws (428) spanner width 13 to the hexagon nuts

(448) applying a torque of 7 Nm.

How to disassemble a rotary actuator

1 Follow the sequence of operation in reverse order.

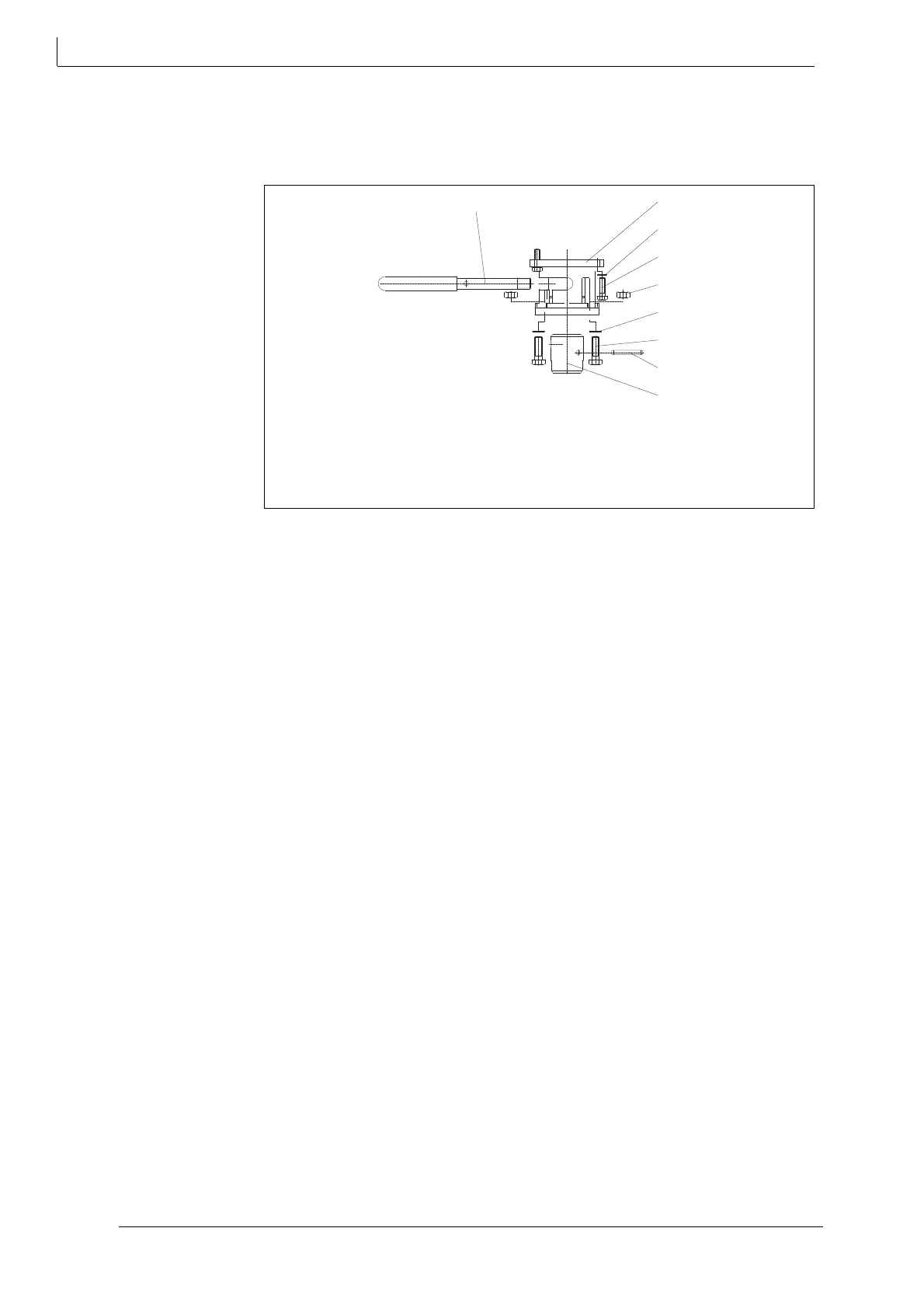

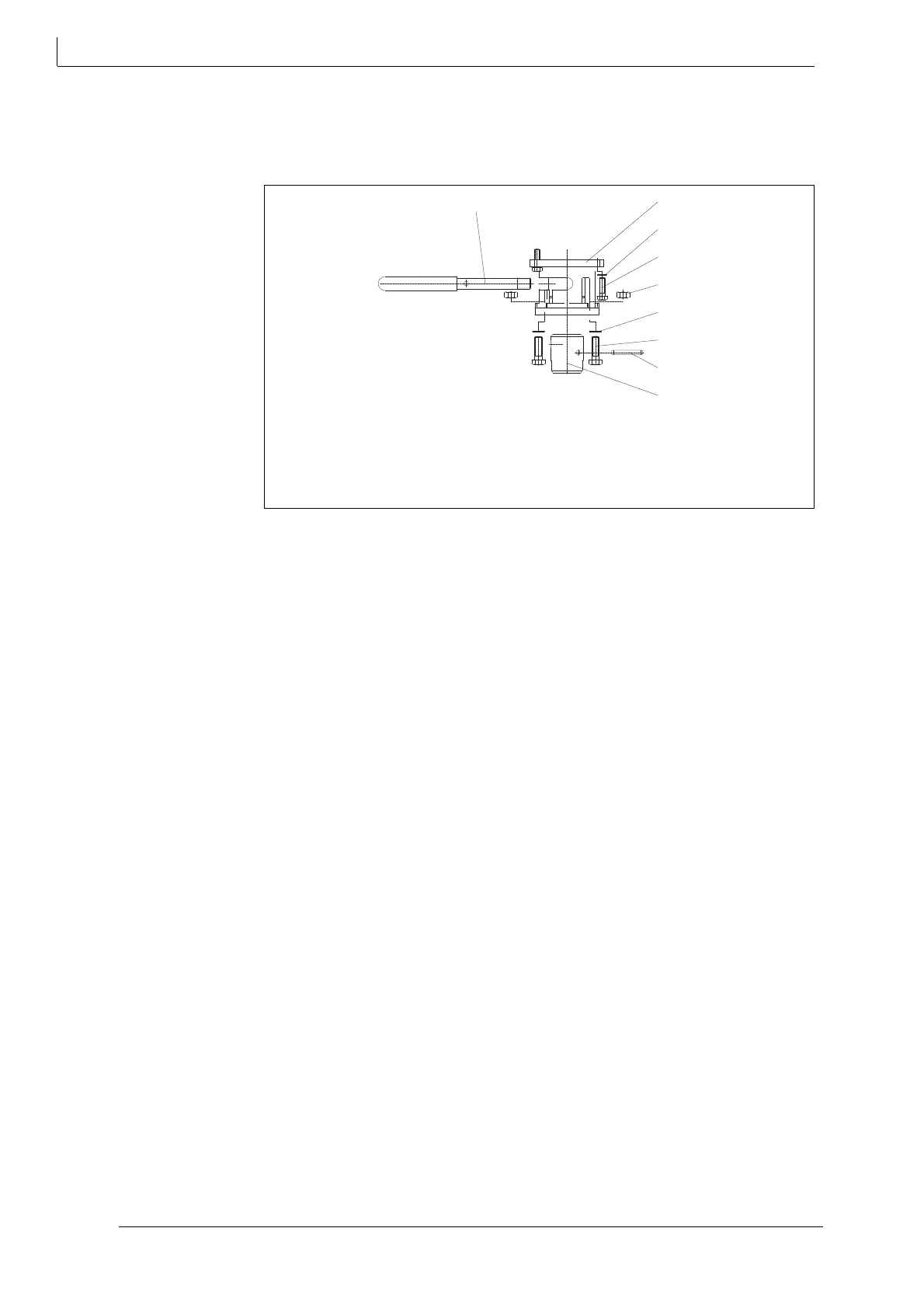

1 Knee-Bracket

6 Coupling

55 Manual lever

306 Thrust washers

308 Thrust washers

351 Spiral clamping pin

426 Hexagon screws

428 Hexagon screws

448 Hexagon nuts

Fig. 7 Add-on kit for flaps

Loading...

Loading...