10 Removal of faults

Rotary actuators 135 • M140 • M150 • M180

26 Version 2.0 - June 2012 Operating instructions

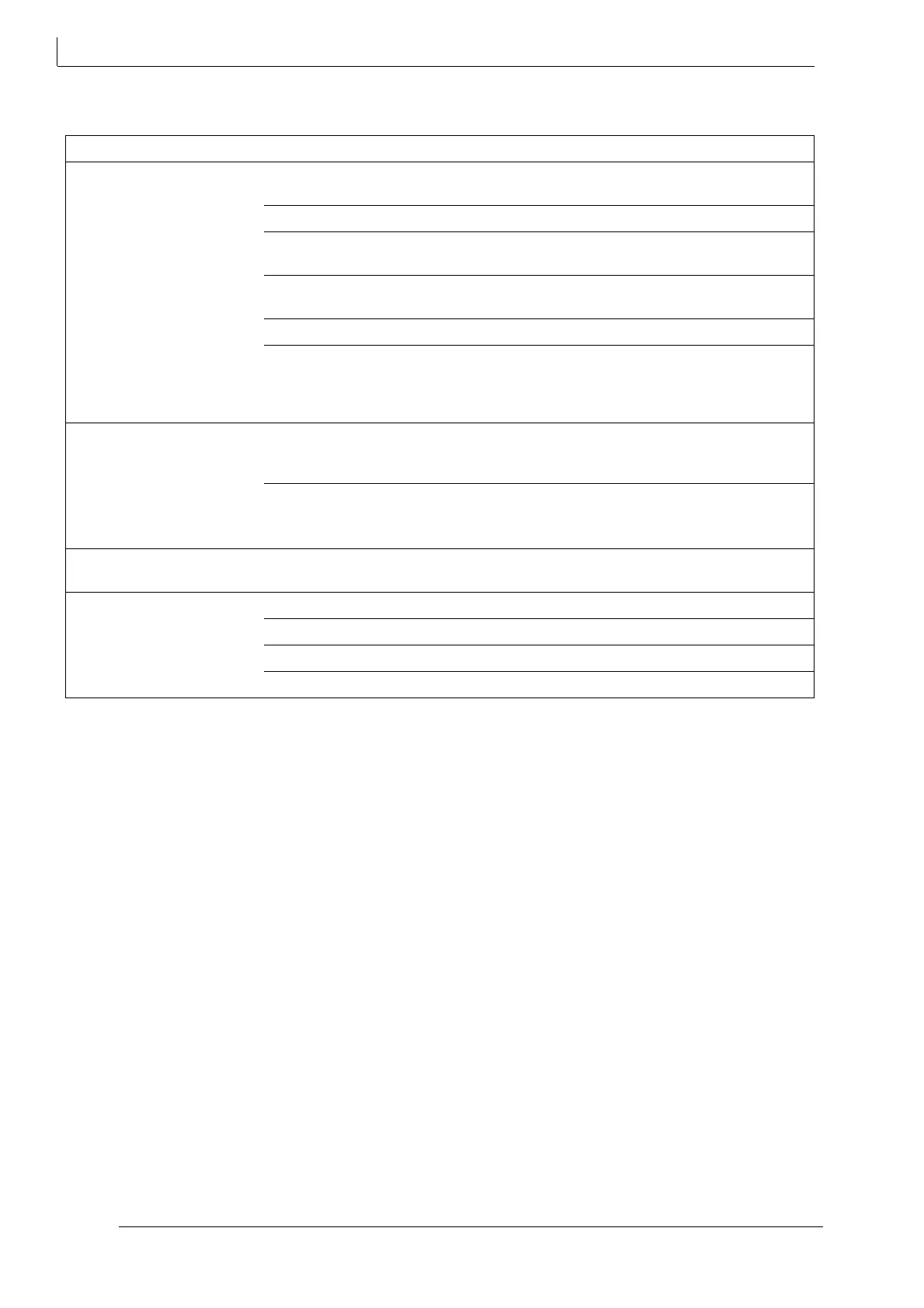

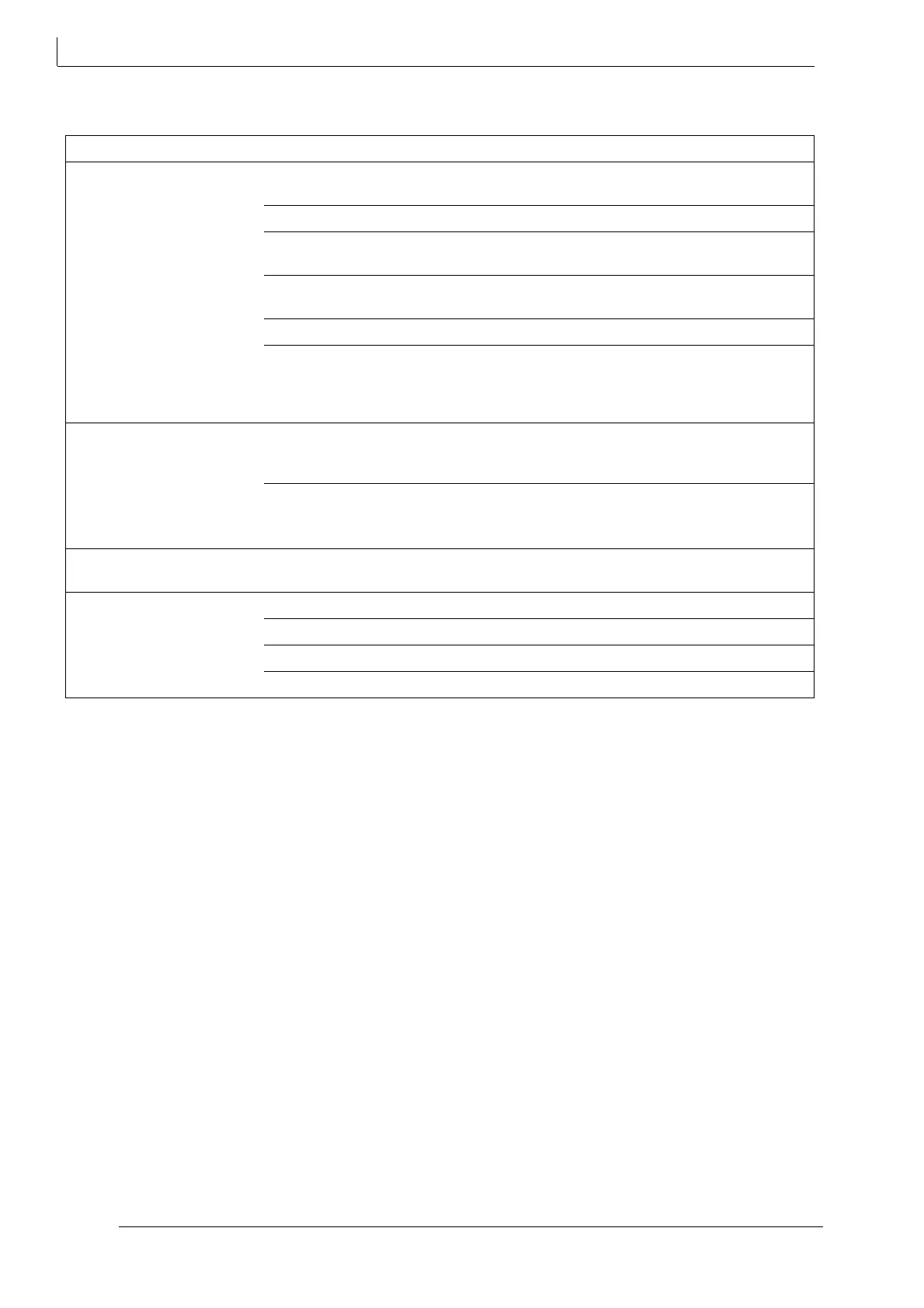

10.2 Check list for breakdown

Fault Cause Rectification

1. Rotary actuator is not

working.

Rotary knob is in MAN position instead of

AUTO

Turn rotary knob to AUTO position,

engage mechanism.

Power cut Determine cause and remedy.

Fuse defective (in control cabinet) Determine cause and remedy, replace

fuse.

Rotary actuator is connected incorrectly Set connection correctly according to

wiring diagram (in the cover).

Short circuit due to incorrect connection Correct setting for connection

Motor has winding damage (burnt-out)

• e.g. voltage too high

Determine cause, measure current data,

Compare to type plate and table,

Disassemble rotary actuator and send it

in for repair.

2. Rotary actuator running

unsteadily, i. e.veering

between clockwise and anti-

clockwise rotation.

Drop of voltage due to excessively long

connecting cables and / or insufficient

diameter.

Measure the current data on the rotary

actuator; if required, re-calculate and

replace connecting cables!

Public power supply fluctuations greater

than admissible tolerance

2.5 Technical data on page 9

Improve public power supply conditions

3. Rotary actuator temporarily

interrupted.

Slack contact in feeder line Check and tighten connections (terminal

strips)

4. Rotary actuator is not

moving to end positions.

Flap is not closing/opening.

End limit position switch incorrectly set Readjust limit position switch

Motor run capacitor defective Replace capacitor

Excessive system pressure Adjust system pressure

Foreign object in flap Remove foreign object and clean flap

table 3 Check list breakdown

Loading...

Loading...