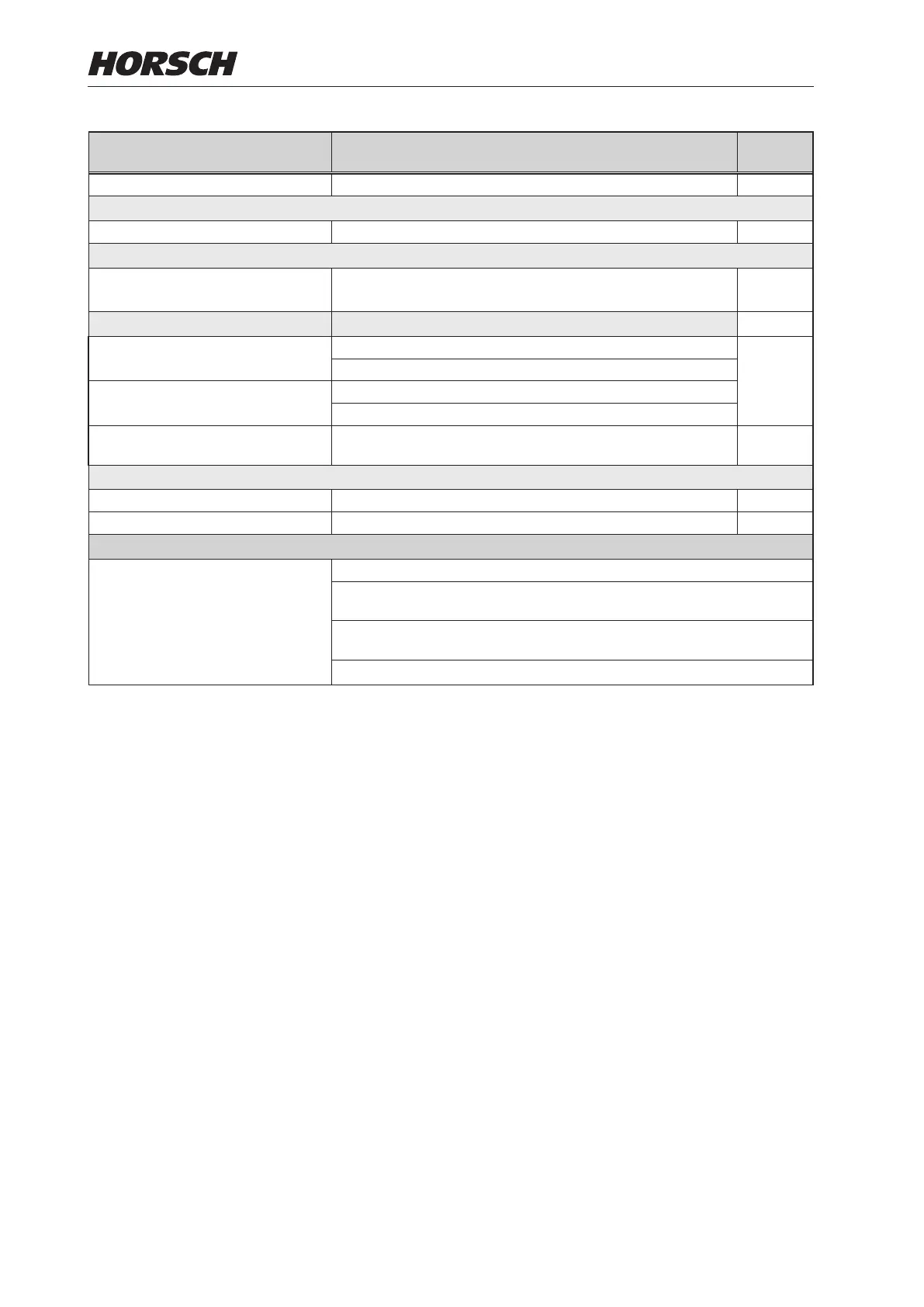

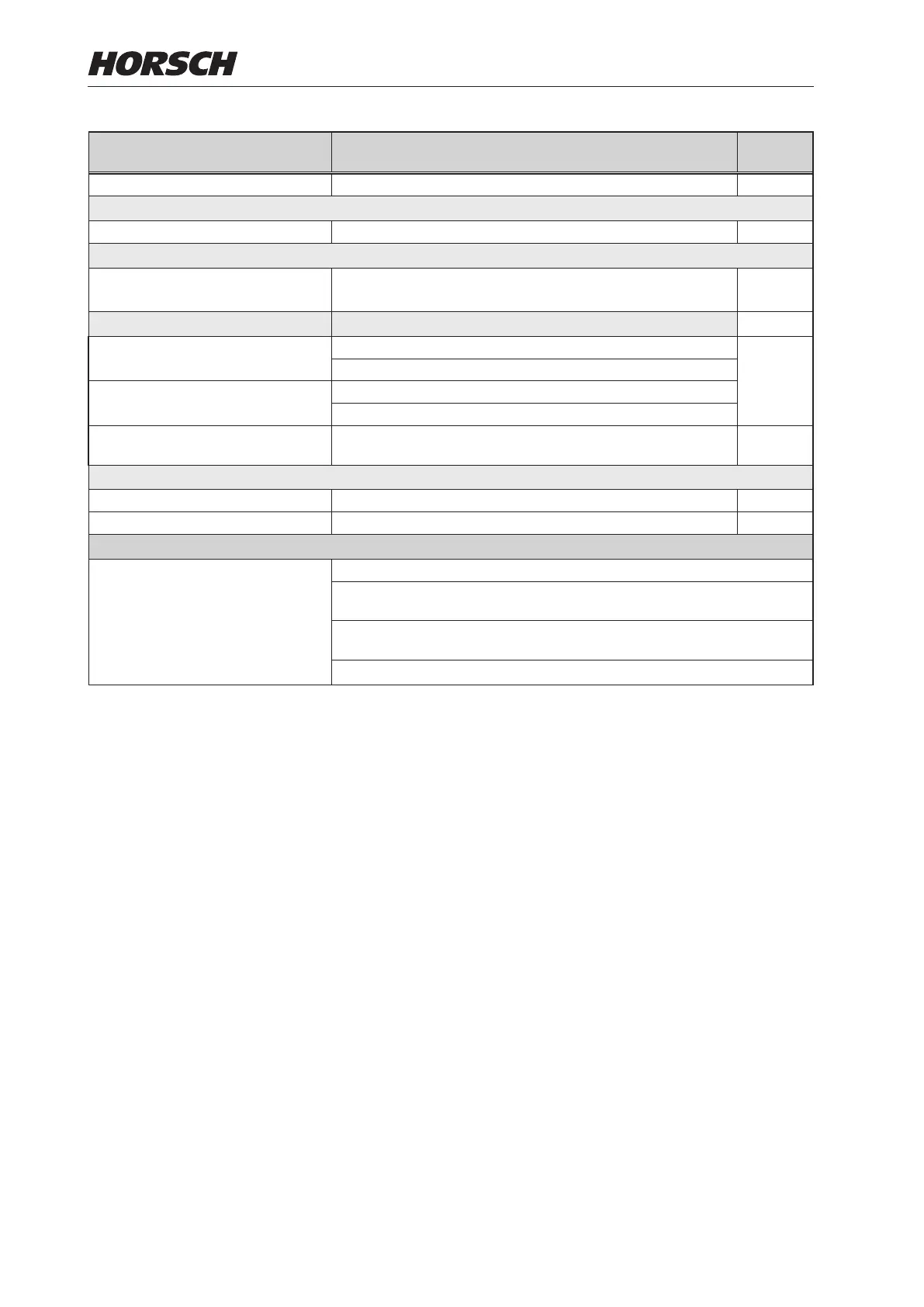

Maintenance location Work instructions Interval

Cutting discs Check for wear. daily

Pneumatic system

Distributor, seed hoses Leak tightness, kinks in hoses, chang and blockage daily

Steering axle

• Check running of the axle behind the seed wagon or tractor.

• Adjust the track if the machine pulls to the left or right.

daily

Wheels

Undercarriage front and rear Check fastening: 510 Nm daily

Check air pressure: 4.3 bar (12 NT) or 4.0 bar (18 NT)

Support wheels front and rear Check fastening: 300 Nm

Check air pressure: 4.3 bar

Bearings of carrying axle journals Check clearance and adjust if necessary (must only be carried

out by an expert workshop)

120 h /

6 months

Safety installations

Lighting and warning boards Check condition and function daily

Warning and safety stickers Check that they are in place and legible daily

At the end of the season

Complete machine Perform care and cleaning work; do not spray plastic parts with oil or similar

Spray the piston rods of the hydraulic cylinder with a suitable corrosion

protection agent

Check all screw and plug-and-socket-connections for rm seating

(see torque table)

Check frame and connecting parts for condition and rm seating

NOTES:

• The maintenance interval Daily designates maintenance on each working day before working with the machine.

• Follow additional maintenance notes in the respective chapters.

46 47

Loading...

Loading...