Chapter 8 Troubleshooting and Maintenance Shenzhen Hpmont Technology Co., Ltd.

―78― HD3L Series Controller User Manual

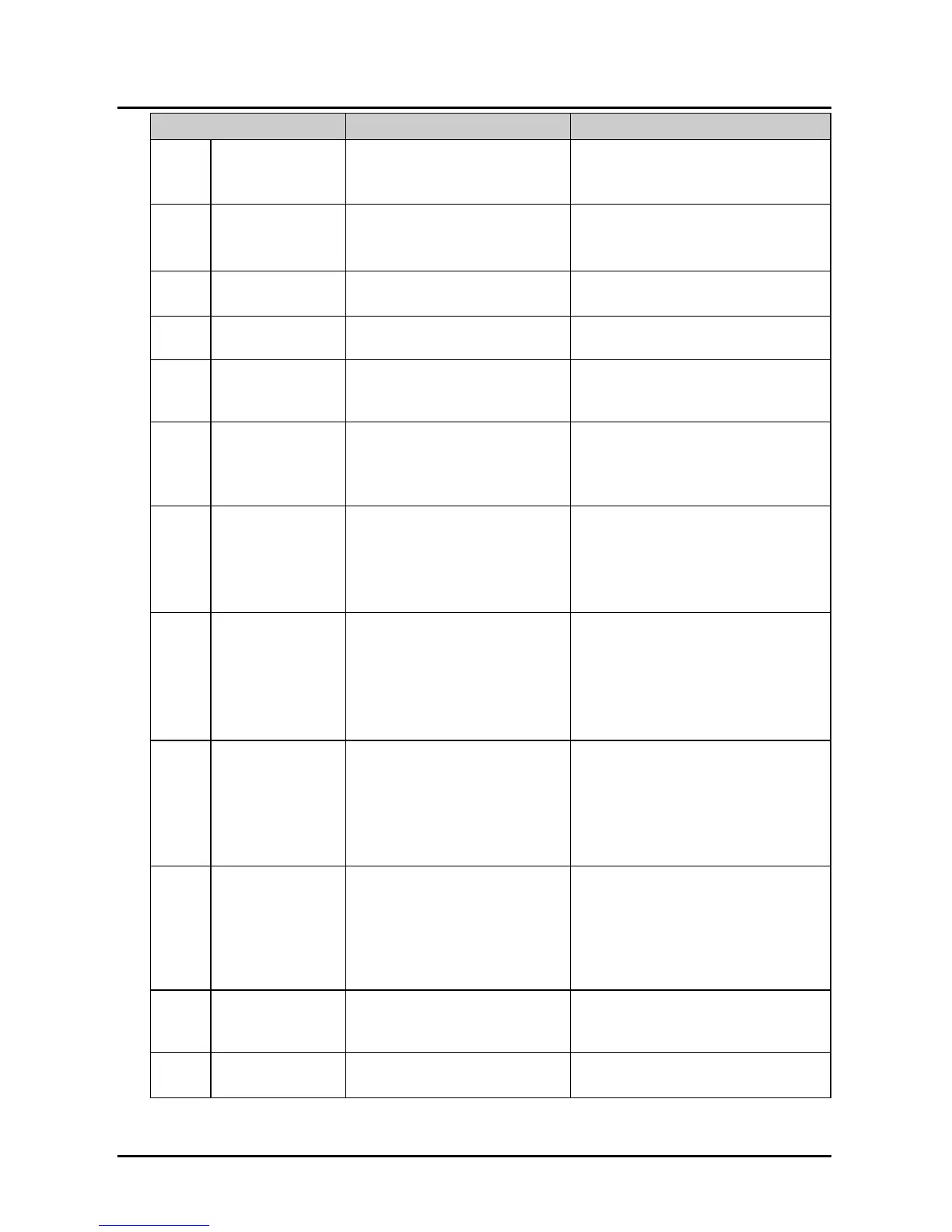

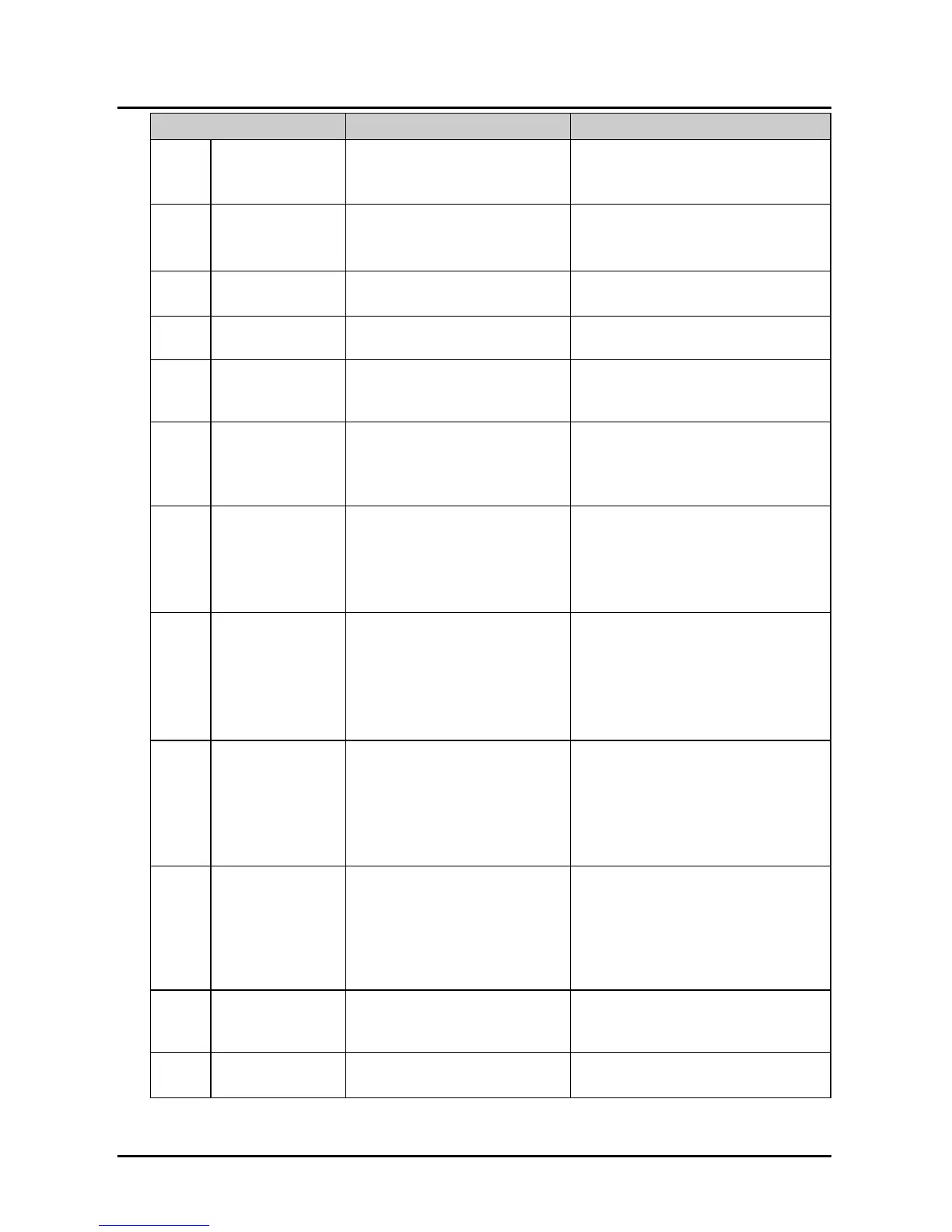

Fault Fault reasons Counter-measures

E0011 CPU fault

• CPU abnormal

• Detect at power on after completely

power outage

• Seek technical support

E0012

Parameter

auto-tuning fault

• Parameter auto-tuning is timeout

• Check the motor connection

• Input correct nameplates parameters

• Seek technical support

E0013

Soft start contactor

failed

• Contactor fault

• Control circuit fault

• Replace the contactor

• Seek technical support

E0014

Current detection

fault

• Current detection circuit is

damaged

• Contact the supplier for repairing

E0015

Input voltage phase

loss

• For three-phase input HD3L, Input

voltage phase loss fault occurs to

power input

• Check the three-phase power input

• Seek technical support

E0016

Output voltage

phase loss

• Output voltage phase

disconnection or loss

• Three-phase load of HD3L is

severely unbalanced

• Check the connection between HD3L

and motor

• Check the quality of motor

E0017 Controller overload

• Acc time is too short

• Improper setting of V/f curve or

torque boost leads to over current

• Mains supply voltage is too low

• Motor load is too high

• Adjust Acc time

• Adjust V/f curve or torque boost

• Check mains supply voltage

• Use controller with proper power rating

E0018

Excessive speed

deviation

• Brake fault or contactor fault

• PG pulse number fault

• Improper setting F05.19, F05.20

• Inadequate controller torque

• Speed-loop PI parameter setting

is incorrect

• Change contactor

• Set proper PG P/R

• Correct the setting of F05.19, F05.20

• Select HD3L with biger capacity

• Correctly set speed-loop PI parameter

E0019 Motor overload

• Improper setting of V/f curve

• Mains supply voltage is too low

• Overload protection factor of

motor is not set properly

• Motor locked-rotor or overload

• Adjust V/f curve

• Check the power input

• Properly set the overload protection

factor of motor

• Check the load and mechanical

transmission devices

E0020 Motor overheat

• Motor overheat

• Motor overheat terminal (DI or AI

terminal) connects incorrectly

• The setting of motor paramteter is

incorrect

• Reduce the load; Increase the Acc / Dec

time; Repaire or replace the motor

• Detect whether the overheat detection

input signal is correct

• Set the motor parameter according to

the nameplate

E0021

Read / Write fault of

control board

EEPROM

• Memory circuit fault of control

board EEPROM

• Contact the supplier for repairing

E0022

Read / Write fault of

keypad EEPROM

• Memory circuit fault of keypad

EEPROM

• Replace the keypad

• Contact the supplier for repairing

Loading...

Loading...