Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Troubleshooting and Maintenance

HD3L Series Controller User Manual ―79―

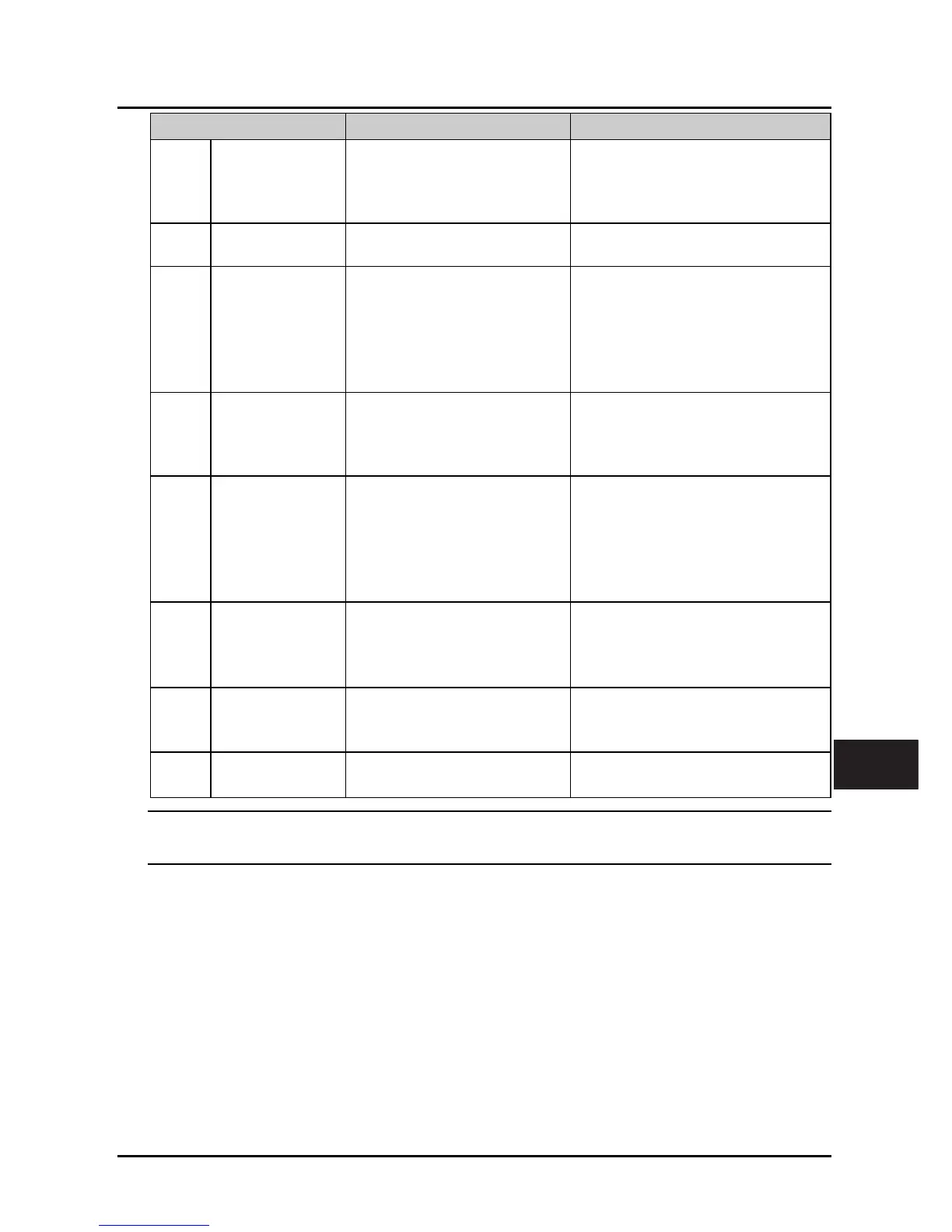

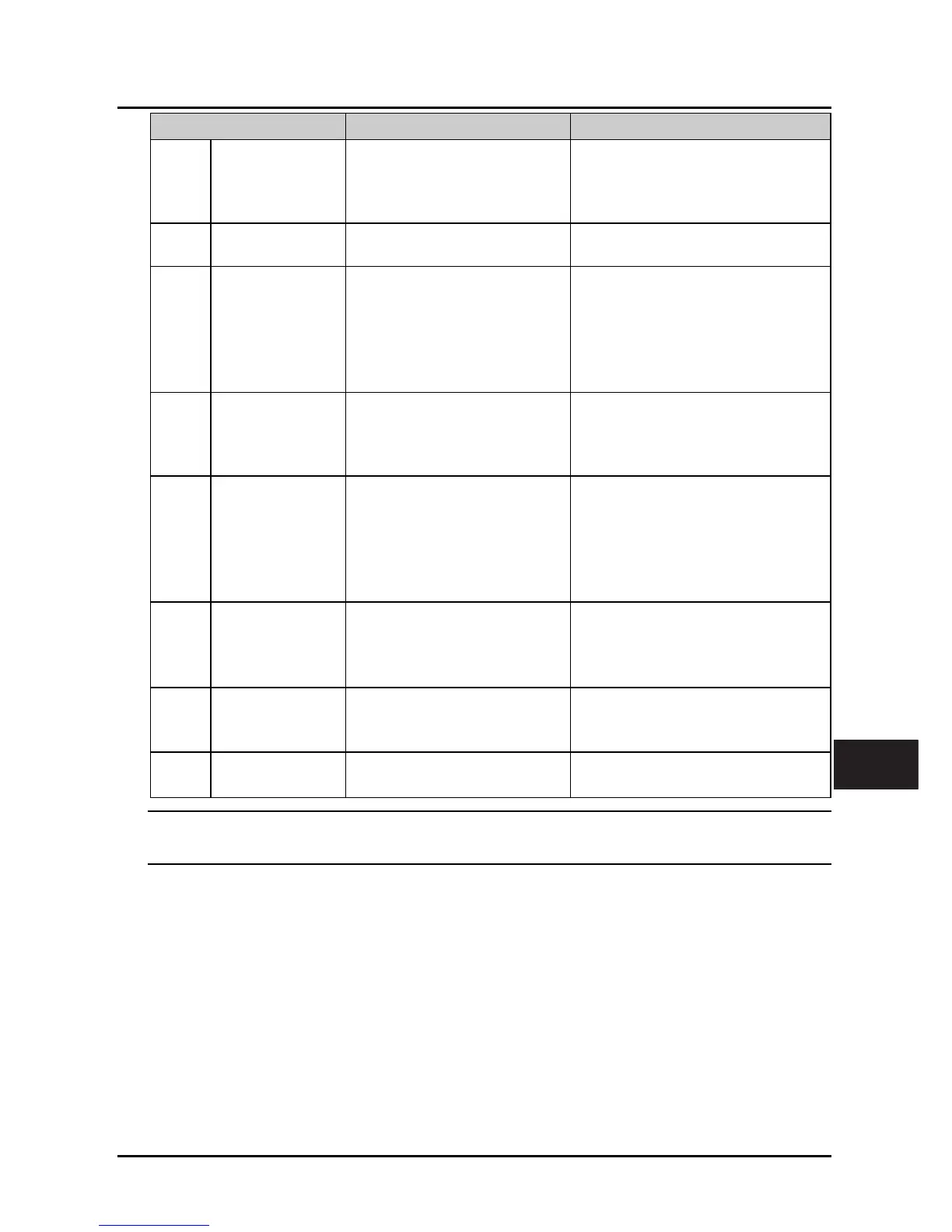

Fault Fault reasons Counter-measures

E0023

Faulty setting of

parameters

• The power rating between motor

and controller is too different

• Improper setting of motor

parameters

• Select a controller with suitable power

rating

• Set correct value of motor parameters

E0024

Fault of external

equipment

• Fault terminal of external

equipment operates

• Check external equipment

E0025

Too small running

current

• Improper setting of F16.14, F16.15

• Correct the setting of F16.14, F16.15

• Check the connection between HD3L

and motor

• Detect HD3L whether output

• Detect whether the output contactor

work is nomal

E0028

SCI ommunication

timeout

• Connection fault of

communication cable

• Disconnected or not well

connected

• Check the connection

E0029

SCI communication

error

• Connection fault of

communication cable

• Disconnected or not well

connected

• Communication setting error

• Communication data error

• Check the connection

• Check the connection

• Correctly set the communication format

and the baud rate

• Send the data according to MODBUS

protocol

E0032

Motor over speed

• PG pulse number fault

• Inadequate controller torque

• Speed-loop PI parameter setting

is incorrect

• Set proper PG pulse number

• Select biger capacity controller

• Correctly set speed-loop PI parameter

E0036

Contator fault

• Contactor damaged

• Feedback contact connection

problem

• Change the contactor

• Check the connection

E0037

Governor fault

• Check external governor

• Check feedback signal

• Replace governor

• Replace circuit

Note:

E0022 does not affect normal run of controller.

8

Loading...

Loading...