11

LP-520 REV. 5.1.17

Table 4 details the relationship of water temperature and time with regard to scald injury and may be used as a guide in determining the

safest water temperature for your applications.

H. HIGH ELEVATION INSTALLATIONS

Natural gas at high elevation might contain less heating value than typical 1,000 BTU/cu ft and therefore can cause improper air / gas

mix leading to improper combustion. For natural gas installations above 3,000 ft, call your gas provider to determine the heating value

of the supplied natural gas.

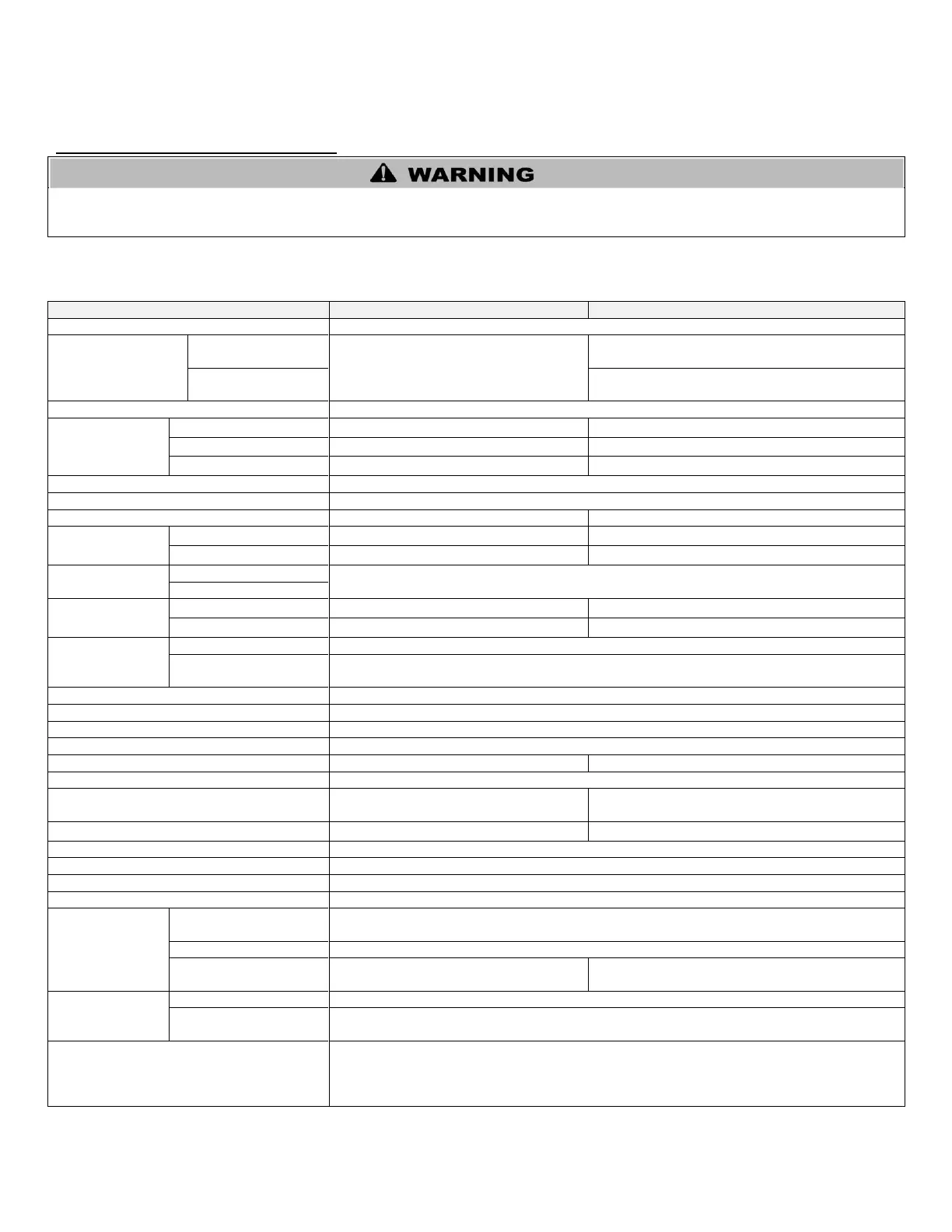

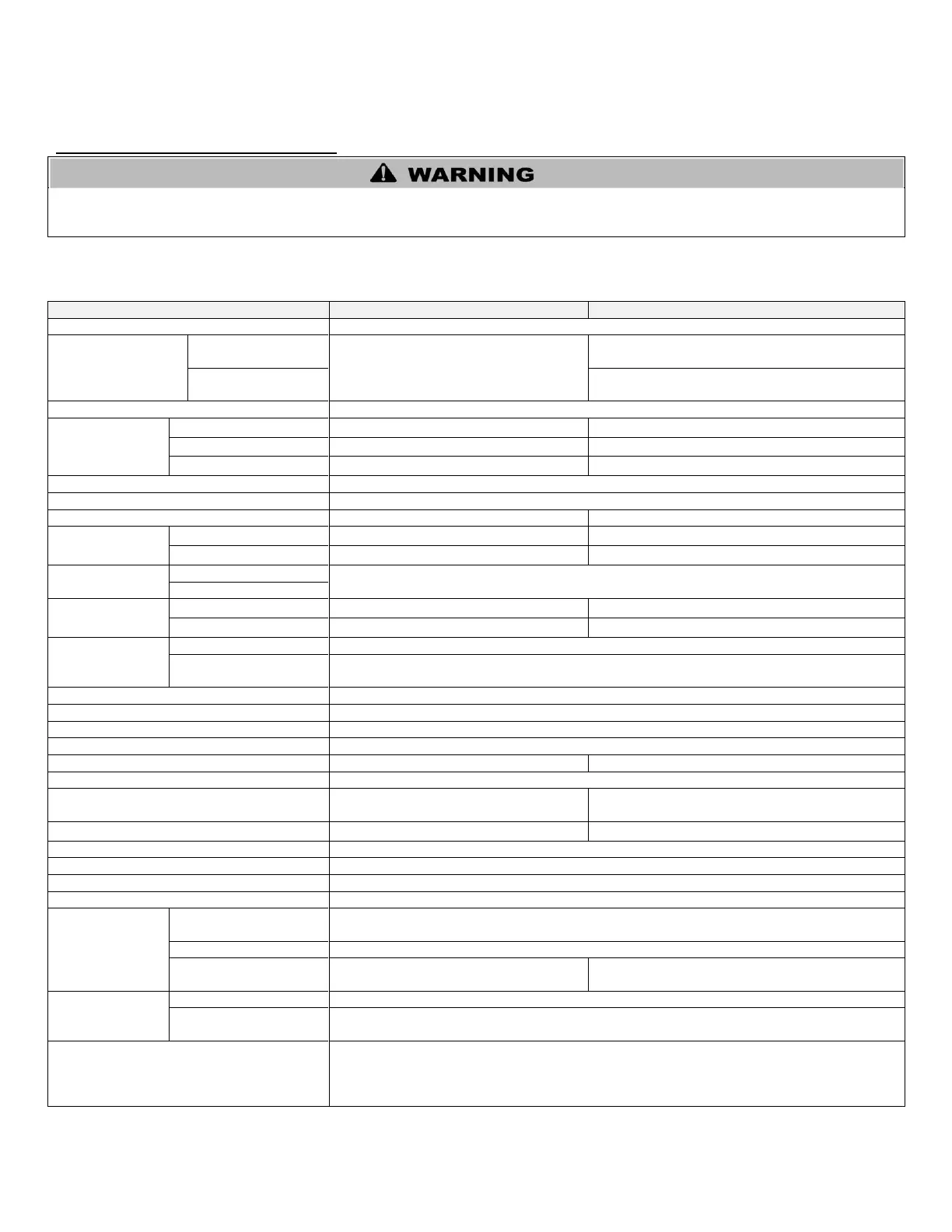

PART 3 – TECHNICAL SPECIFICATIONS

Indoor, Wall Mount, Fully Condensing

Minimum /

Maximum Input

(Btu/Hr)

Sealed Combustion Direct Vent, Power Vent

2” (50 feet), 3” (100 feet)

Shipping Weight (lbs est.)

NG/LP: -0.134’WC / -0.173”WC

Maximum Power

Consumption

Direct Electronic Ignition / Automatic Flame Sensing

Single Orifice Premixed Fuel Modulation Ceramic Fiber Infrared

Combination Modulating (Current Proportional)

W 17.25” – H 34” – D 15.5”

Internal Storage Tank Water Capacity

(DHW)

Main Controller / Control Panel

NGTX-900C / P-920C_CB-HTP

DHW Inlet / Hot

Water Outlet

½” NPT (1/2” X ¾” Bell Coupling

Provided to Upsize Gas Line)

Primary Heat Exchanger: Stainless Steel

Storage Tank: Stainless Steel

Optical Flame Sensor, Burner Plate High Limit (392

o

F), Water Temperature High Limit

Sensor (200

o

F), Freeze Protection (Three Stage Operation - Activates at 46

o

F – See

Freeze Protection in Installer Menu for Details), Exhaust Temperature High Limit Sensor

(190

o

F), Blocked Flue Switch, Condensate Switch, Built-In Low Water Cut-Off Probe

Table 4 – Technical Specifications – NOTE: 199W Models Offer a Maximum BTU/Hr Input of 140,000 as Shipped. Maximum

BTU/Hr can be increased up to 199,000 BTU/Hr with a Larger External Pump Installed in the Primary Loop

Loading...

Loading...