25

LP-520 REV. 5.1.17

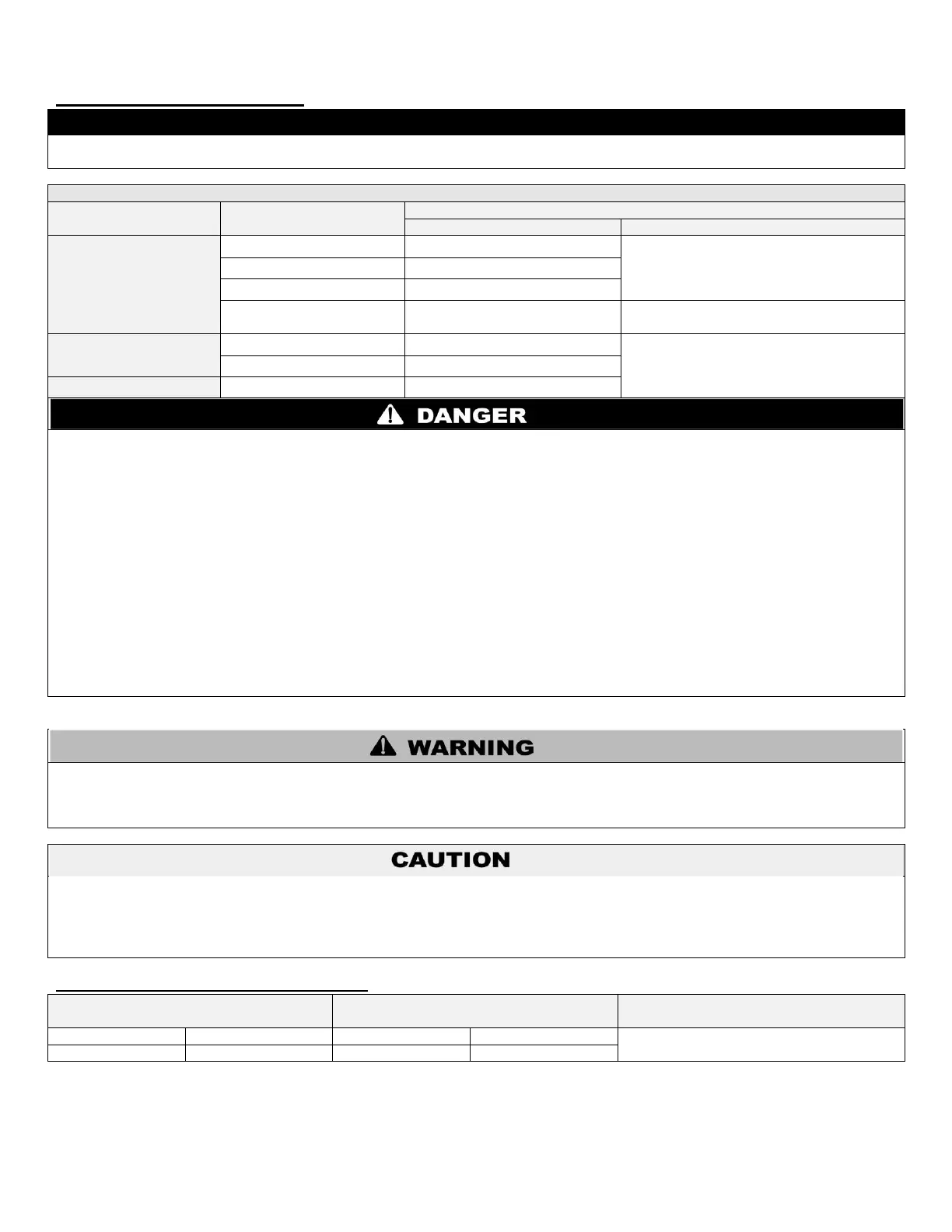

B. APPROVED VENT MATERIALS

Consult Table 9 or the most recent edition of ANSI Z223.1/NFPA 54 or CAN/CGA B149.1 as well as all applicable local codes and

regulations when selecting vent pipe materials.

APPROVED EXHAUST VENT AND INTAKE PIPE MATERIAL

Standards for Installation in:

Exhaust vent or Intake

pipe and fittings

PP, CPVC, and PVC venting must be

ULC-S636 Certified. IPEX is an approved

manufacturer in Canada, supplying vent

material listed to ULC-S636.

Certified for Category IV and

direct vent appliance venting

Certified for Category IV and direct vent

appliance venting

IPEX System 636 Cements & Primers

• The exhaust and intake components installed with this water heater must be used for near water heater piping BEFORE

transitioning to the approved materials listed above. DO NOT REMOVE these installed components. Doing so WILL VOID

warranty.

• PVC/CPVC pipe and fittings of the same diameter are considered interchangeable.

• Use of cellular core pipe PVC (ASTM F891), cellular core CPVC, or Radel® (polyphenysulfone) in nonmetallic venting systems

is prohibited.

• DO NOT connect PVC/CPVC to Polypropylene without an approved vent connector.

• Any transition to Polypropylene MUST be done in the vertical within five (5) feet of the appliance.

• When installing AL29-4C vent piping, install a PVC-to-stainless adapter at the water heater vent connection, and at the

termination when using an HTP PVC termination kit. DO NOT mix AL29-4C piping from different manufacturers unless using

adapters specifically designed for the purpose by the manufacturer.

• Covering non-metallic vent pipe and fittings with thermal insulation is prohibited.

• DO NOT obstruct the flow of combustion or ventilation air.

• When using Pipe Cement/Primer, follow the instructions included with the Cement/Primer closely. Clean and dry all applicable

surfaces before applying.

Failure to follow these directions will result in substantial property damage, severe personal injury, or death.

Table 11 – Approved Venting Materials

Vent adaptors are not designed as load-bearing devices, and must not be used to support exhaust vent piping. All vent pipes must be

properly connected, supported, and the exhaust must be pitched a minimum of ¼” per foot back to the appliance to allow drainage of

condensate. Failure to properly support vent piping and follow the information in this statement could result in product damage, severe

personal injury, or death.

High heat sources (sources generating heat 100

o

F / 37

o

C or greater, such as stove pipes, space heaters, etc.) may damage plastic

components of the appliance as well as plastic vent pipe materials. Such damages ARE NOT covered by warranty. It is recommended

to keep a minimum clearance of 8” from high heat sources. Observe heat source manufacturer instructions, as well as local, state,

provincial, and national codes, laws, regulations and ordinances when installing this appliance and related components near high heat

sources.

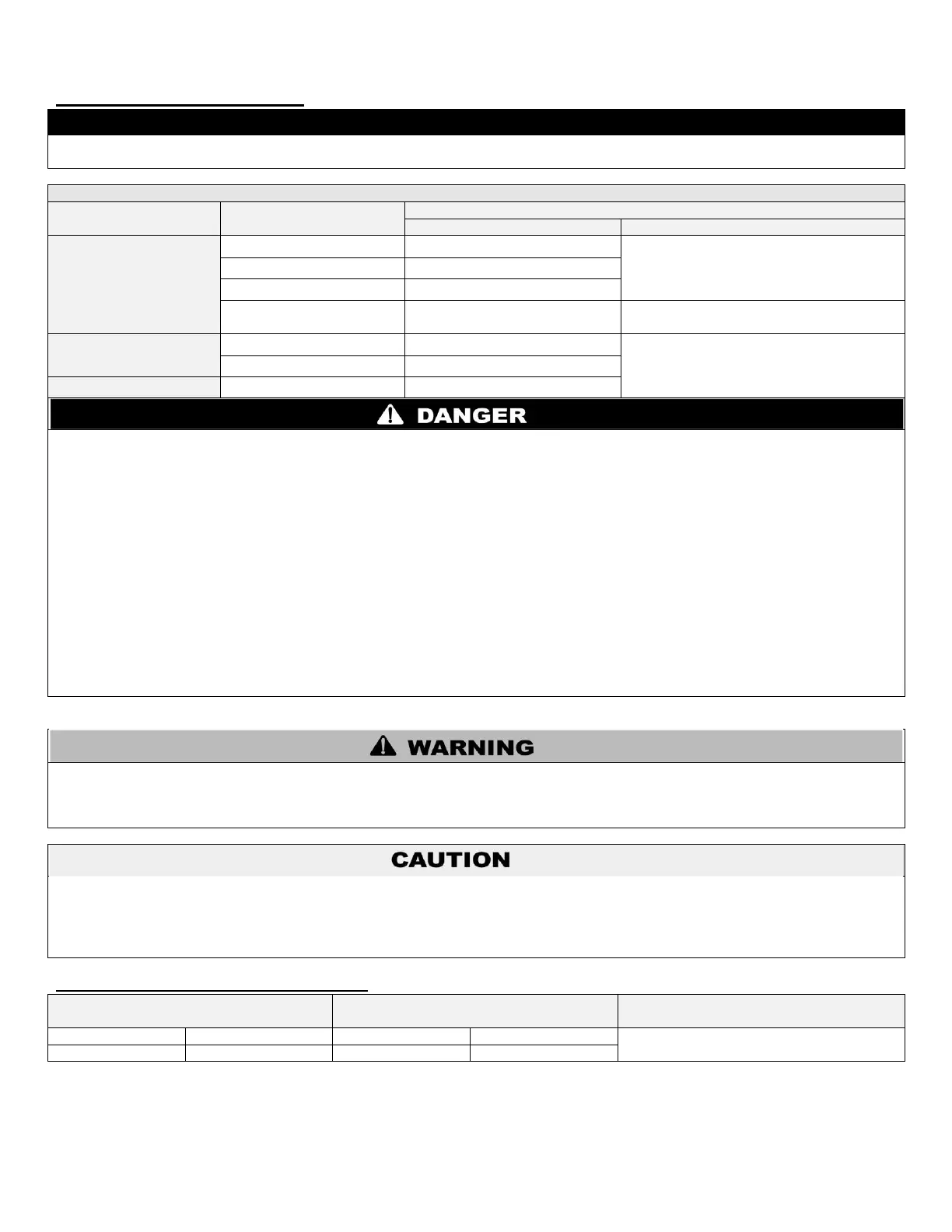

C. ALLOWED COMBINED VENT LENGTHS

MAXIMUM # OF 90

o

ELBOWS

(2” and 3” VENT DIAMETERS)

Table 12 – Approved Vent Lengths

The total equivalent length of exhaust vent and intake pipe should not exceed fifty (50) feet (15M) in 2” pipe, or one hundred (100) feet

(30M) in 3” pipe.

a. The equivalent lengths of friction loss in elbows are listed below:

• 5 feet (1.5M) for each additional 3” 90

o

elbow

Loading...

Loading...