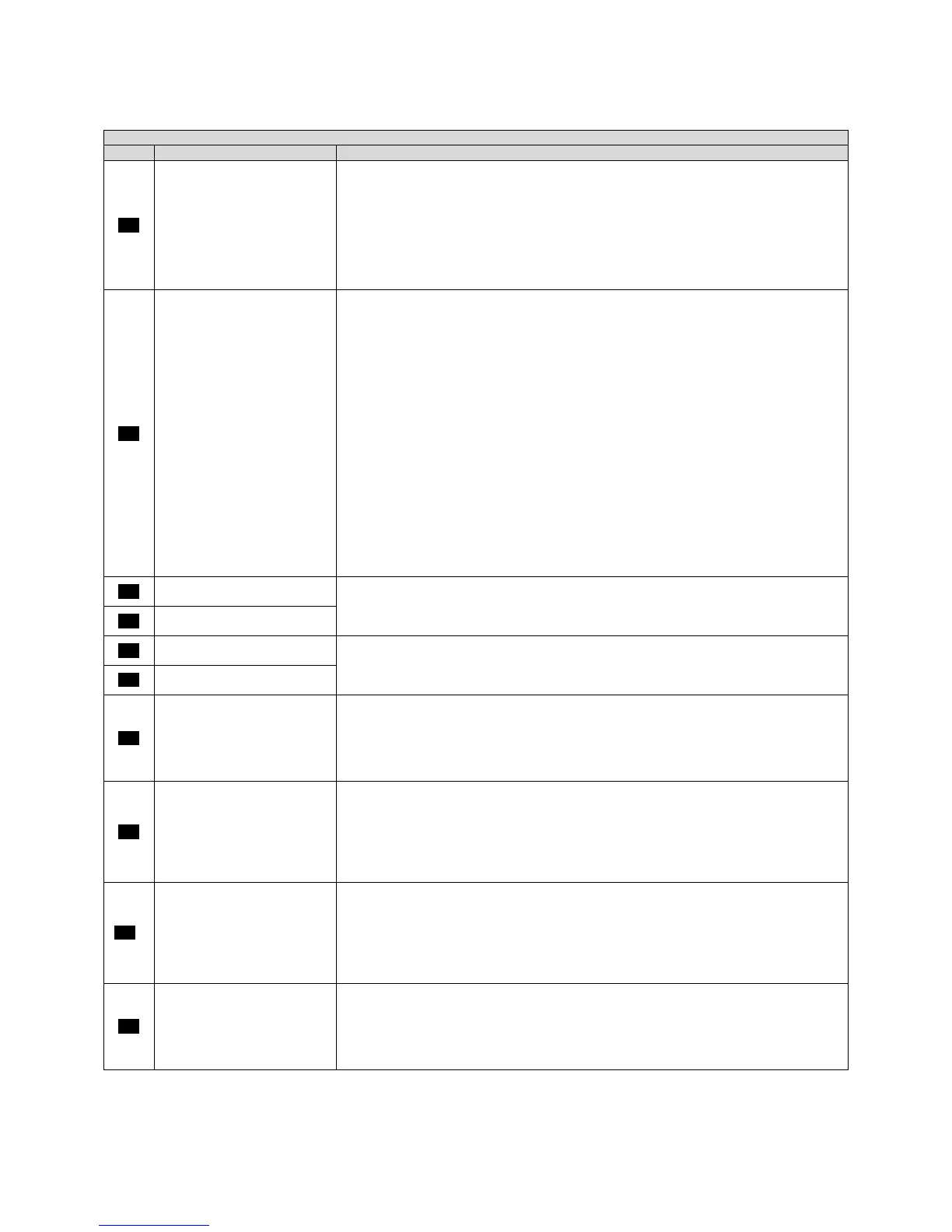

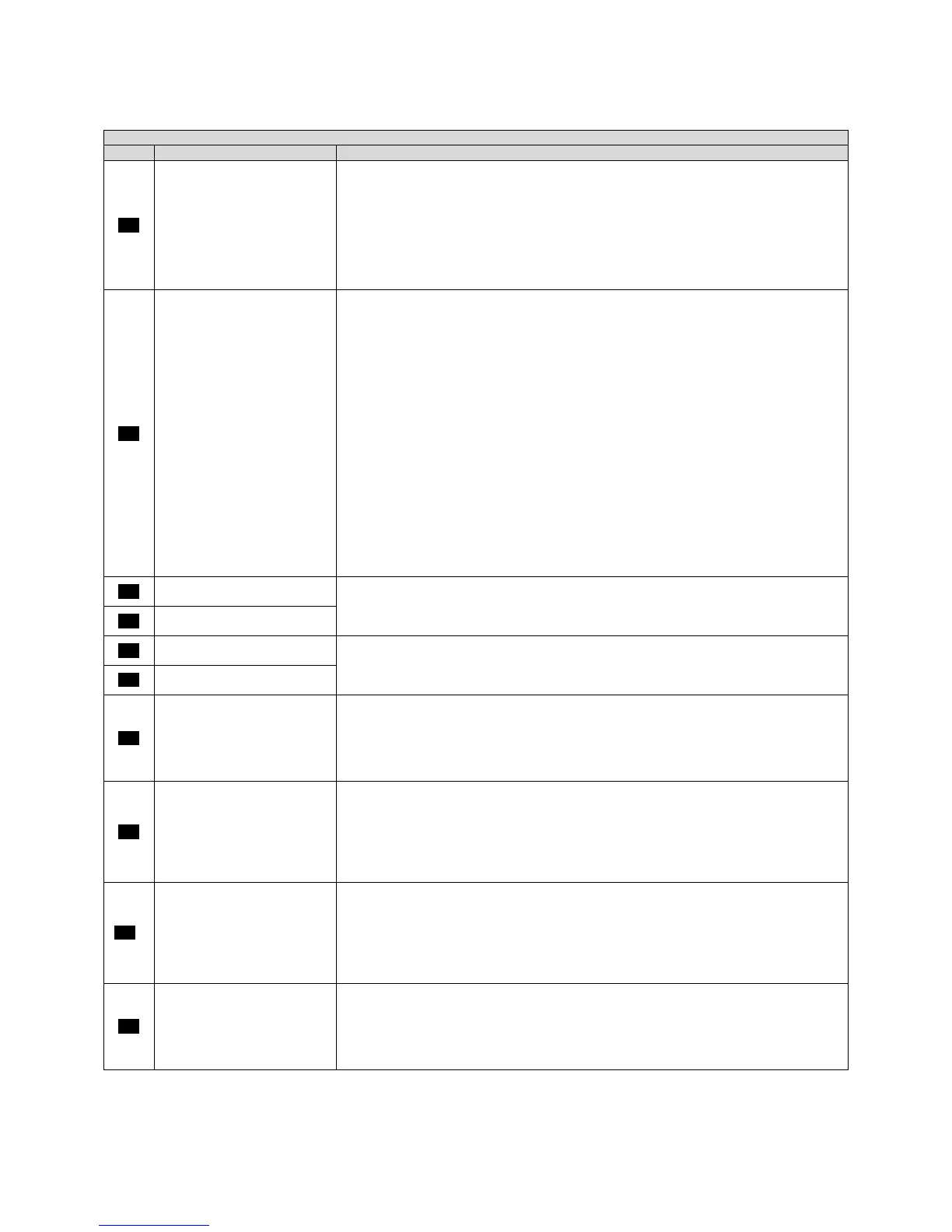

50

F00

High temperature switch limit

exceeded 194

o

F.

1. Try reset. If F00 repeats, create a demand for hot water. (DANGER: Use caution to

prevent burn injury.) If water is above 194

o

F, test upper and lower temperature sensor

with an ohmmeter. (Refer to resistance chart, this section.) Replace bad sensor. If water

is below 194

o

F, test high temperature switch and wiring with ohmmeter. Switch should be

closed at this point. If not, replace switch.

2. If unit did reset successfully, let the heater run and go into the status menu to check the

upper and lower temperature sensor. If either reading displayed does not make sense,

check appropriate sensor with ohmmeter. (Refer to resistance chart, this section.)

Replace bad sensor. Do an OHMs reading on both sensors to check continuity.

F01

Vent temperature limit

exceeded.

1. Inspect all flue piping. If the flue is damaged or shows signs of overheating, repair or

replace the flue parts as necessary before proceeding.

2. If the flue piping system is intact, not damaged and there is no sign of the flue

overheating (such as discoloration or melting), push the red reset button on the flue

switch

3. Be sure the heater is connected to a water supply and full of water.

4. Push the RESET button on the heater control panel. The appliance should light. If the

appliance lights, proceed to step 5. If the appliance does not light and the display again

begins to flash F01, inspect the wiring to the flue switch, repairing or replacing as

necessary. If the wiring is intact, replace the flue switch, using care to mount the new flue

switch in the same position and mounting holes as the old one. If the display flashes a

code other than F01, follow the troubleshooting guide for that code.

5. Observe operation for 5 minutes. Place the probe of an exhaust analyzer into the flue

system within 6 feet of the heater. The exhaust temperature should not rise above 190

o

F

after several minutes of operation.

6. If the flue temperature is below 190

o

F and the heater again goes into lockout displaying

F01, replace the flue switch, using care to mount the new flue switch in the same position

and mounting holes as the old one. If the display flashes a code other than F01, follow the

troubleshooting guide for that code.

7. If the flue temperature increases to over 190

o

F, consult HTP for further assistance.

F02

Interrupted or shorted upper

temperature sensor.

1. Check the electrical connection to the appropriate temperature sensor.

2. If connection is okay, replace bad sensor.

F03

Interrupted or shorted lower

temperature sensor.

F05

Upper temperature sensor

o

1. If water in tank is not greater than 194

F, check wiring. Repair if faulty.

2. If wiring is okay, check appropriate sensor with ohmmeter and compare to reading in

resistance chart above. If reading does not agree with water temperature, replace bad

sensor.

F06

Lower temperature sensor

exceeds 194

o

F.

F09

No flame detected – Heater

will make three attempts at

ignition before the control

goes into this lockout

condition. Will reset in 1 hour.

1. Watch the igniter through the observation window provided.

2. If there is no spark, check the spark electrode for the proper ¼” gap.

3. Remove any corrosion from the spark electrode and flame rectifier probe.

4. If there is a spark but no flame, check the gas supply to the heater.

5. If there is a flame, check the flame sensor.

6. Check any flue blockage or condensate blocks.

F10

Loss of flame signal – The

heater will relight 4 times

before the control goes into

this lockout condition. Will

reset in 1 hour.

1. Monitor the gas pressure to the unit while in operation.

2. Assure that the flame is stable when lit.

3. Check to see if the green light on the display module is out while the heater is running.

4. If the green light doesn’t come on or goes off during operation check the flame signal

on the status menu.

5. If the signal reads less than 1 microampere, clean the flame rectifier probe.

6. If the flame rectifier probe continues to read low, replace it.

F11F

False flame signal – The

heater will lock out if it senses

a flame signal when there

should be none present.

1. Turn the gas off to the unit at the service valve.

2. If the flame signal is still present replace the igniter.

3. If the flame signal is not present after turning off the gas supply, check the gas valve

electrical connection.

4. If there is no power to the gas valve, remove the valve and check for obstruction in the

valve seat or replace the gas valve.

5. Turn the gas on at the service valve after corrective action is taken.

F13

incorrect – The heater will

lock out if it senses that the

fan speed is less than 70% of

expected rate for more than

1. Check the combustion air fan wiring.

2. Replace the combustion air fan.

3. Replace the control board.

Table 13 NOTE: If you replace a part to remedy a fault, it is recommended that you cycle the unit at least

three or four times to assure the fault has been resolved.

Loading...

Loading...