23

10

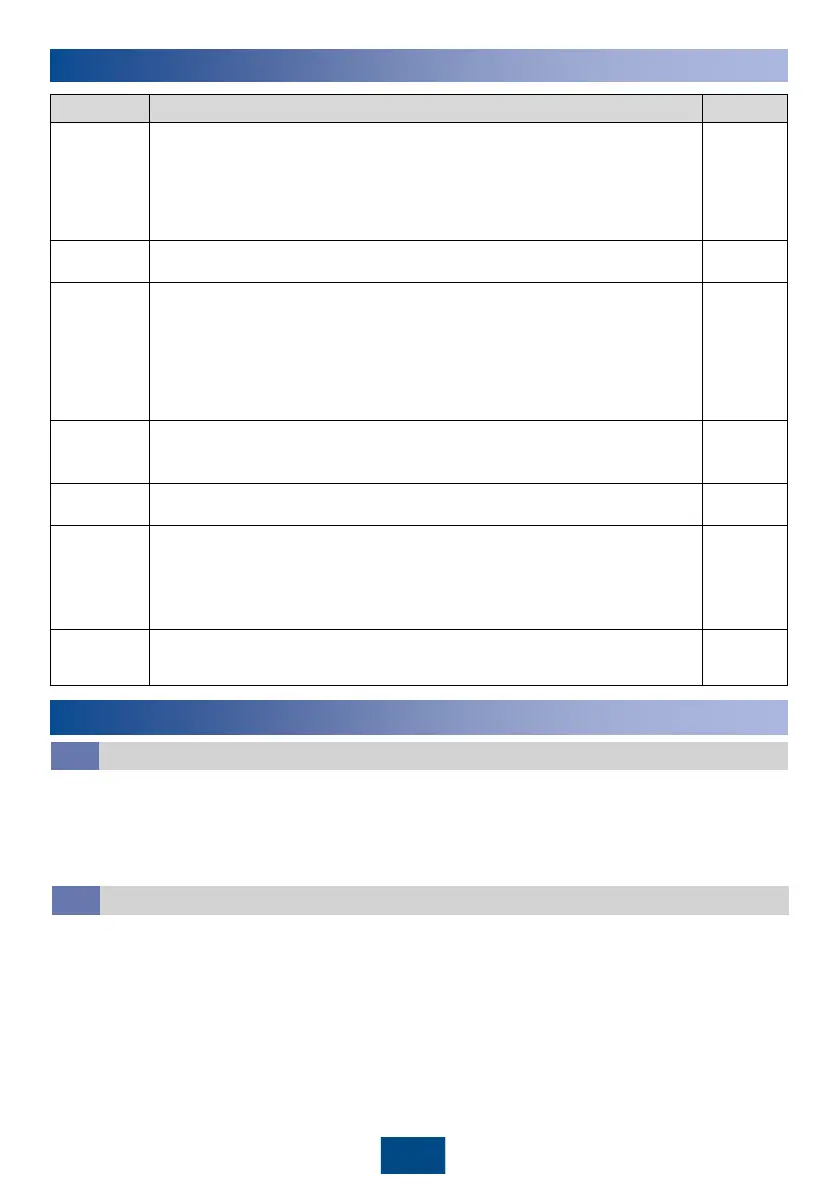

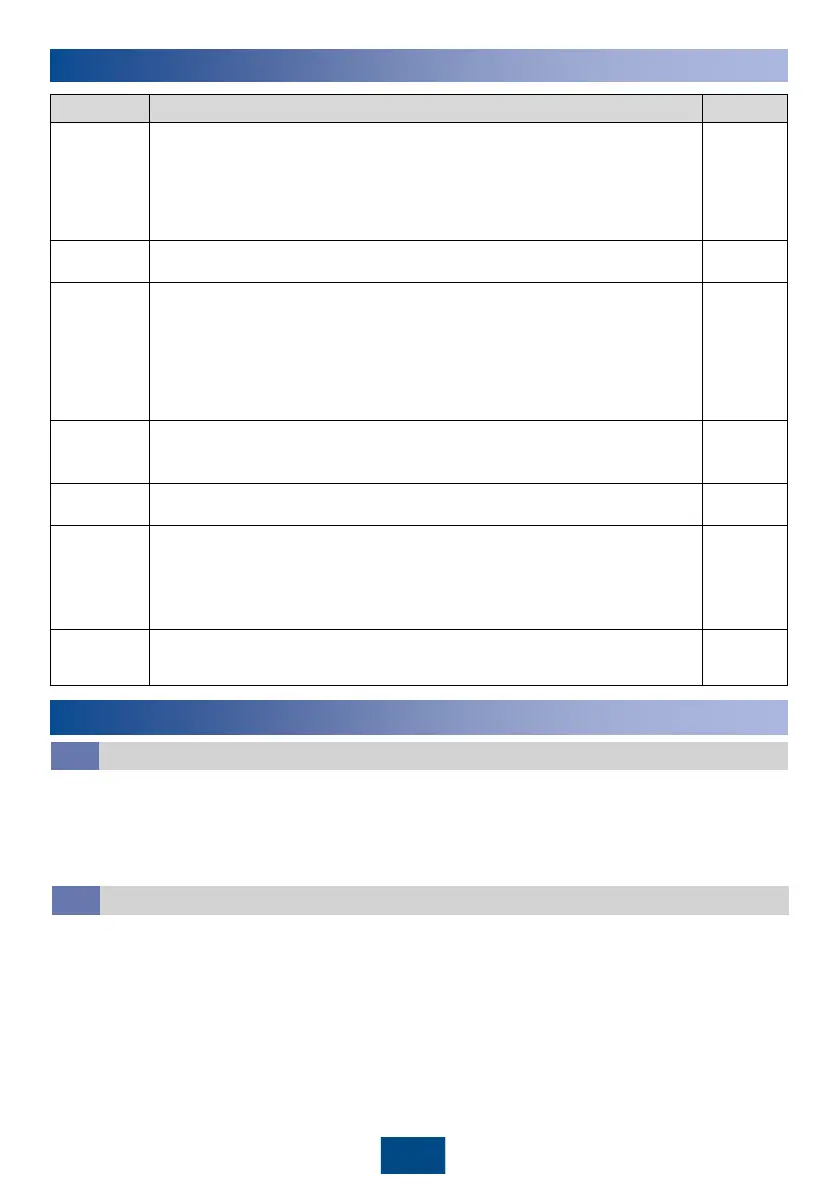

Post-Installation Check

Item Content Result

Refrigerant

pipe

Ports are connected properly. The pipeline has oil traps, inverted U-shaped

traps, gradients (for the refrigerant pipes) , and pipe supports. Pipes are

securely connected. All pipes are wrapped with thermal insulation foam,

and the insulation foam is intact. The needle valve plug is secured (torque

of 0.45

±

0.05 N•m) , and valve bonnet is tightened. The pipes have no

sharp bends.

□

Passed

□

Failed

Waterway Water pipe joints have been sealed. The drainpipe is securely connected.

□

Passed

□

Failed

Electricity

Cables are not damaged or over-bent. The power cables and outdoor unit

(water-cooled module) , The signal cables and outdoor unit (including

smart cooling product monitoring board) or water-cooled module, water

sensor, the teamwork cable, and the T/H sensor cable are connected as

required. The rated specifications of the upstream switch meet the

maximum current requirement. All cable connectors are secured. Indoor

and outdoor units are properly grounded.

□

Passed

□

Failed

Cabinet

The cabinet is installed properly, without any tilt. The cabinet should be

secured. The foreign matter inside the cabinet such as cable ties and cable

cuts is cleaned up.

□

Passed

□

Failed

Compressor

The transport fasteners of the compressor are removed. The bolts on the

compressor are tightened.

□

Passed

□

Failed

Outdoor

unit

The fan blades do not interfere and protective cardboards for fins are

removed. Bonnets of needle valves and water-proof connectors are

tightened. Cables are protected by tubes and the cable outlet faces

downward. Glue is applied to the waterproof connector when the outdoor

unit is placed vertically and the waterproof connector faces upward.

□

Passed

□

Failed

Water valve

actuator

The actuator manual button is reset (ejected state) .

□

Passed

□

Failed

11

Leak Checking, Vacuuming, and Precharging Refrigerant

Charge 3.0 MPa nitrogen and preserve the system for 24 hours. If the ambient

temperatures before and after the preservation are similar, the system pressure should

not drop. If leaks occur after the preservation, check them along the pipe, especially at

the welding positions, needle valve, and angle valve.

The vacuuming time should be 80 minutes at least and the final pressure (absolute pressure)

should be 60 Pa at most. When the pressure stops dropping, pump for another 10 minutes.

After the vacuumization, close all the vacuum pump and valves. Preserve the system for

another 10 minutes and the pressure (absolute pressure) should be 90 Pa at most. If the

pressure gauge cannot be precise at 60 Pa, ensure that the pressure is displayed at the

minimum scale. Extend the preservation time to one hour. Then check whether the pressure

displayed on the pressure gauge increases.

Leak Checking

11.1

Vacuuming

11.2

Loading...

Loading...