Function description

OPERATION MANUAL Chapter 3

Unistat® V2.0.0en/09.06.16//15.09

- Always adjust the inside diameter of temperature control hoses to the pump connections.

- The viscosity of the thermal fluid determines the pressure drop and affects the tempera-

ture control results, particularly at low operating temperatures.

- Too small connectors and couplers and valves can generate significant flow resistance.

Your application will therefore be slower to reach its design temperature.

▪ Basically, you should only use the thermal fluids recommended by the manufacturer and only

within the usable temperature and pressure range.

▪ With temperature control close to the boiling temperature of the thermal fluid, the application

should be roughly at the same height or below the temperature control unit.

▪ Fill the temperature control unit slowly, carefully and evenly. Wear the necessary personal pro-

tective equipment, such as goggles, heat-proof and chemicals-resistant gloves, etc.

▪ After filling and setting all the requisite parameters, the temperature control circuit must be

vented. This is required to ensure trouble-free operation of the temperature control unit and

hence your application.

For water-cooled temperature control units, please take the cooling water temperature necessary

for perfect operation and the required differential pressure from the data sheet from page 96

onward in the Section »Annex«.

3.4 “Pilot ONE®” controller

Figure »”Unistat Control ONE” and “Pilot ONE”« are shown on page 6.

The basic version of the "Pilot ONE" (Basic) can be upgraded in two stages (from Basic to Exklusiv

and from Exklusiv to Professional or from Exklusiv to Professional with DV-E-grade).

3.4.1 Functional overview of “Pilot ONE®”

Temperature control units E-grade Basic

E-grade

Exclusive

E-grade

Professional

Brewing thermostats

Unistat temperature control units

UniCAL

Other temperature control units

= Standard equipment,

= Optional,

= Not possible

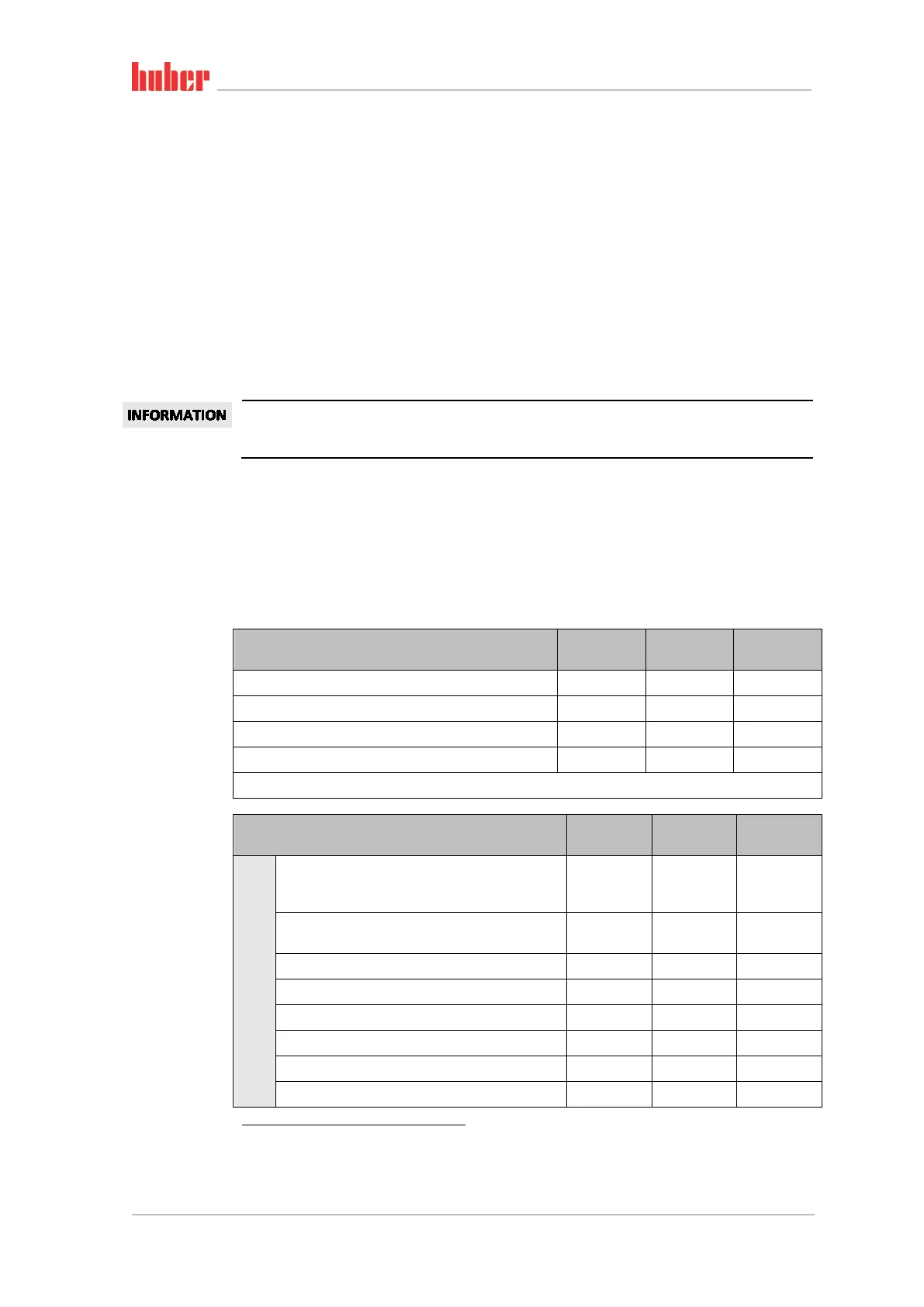

Function E-grade Basic

E-grade

Exclusive

E-grade

Professional

Temperature control

Controller parameterization predefined

1

TAC (True

Adaptive

Control)

TAC (True

Adaptive

Control)

Sensor calibration for control sensor (internal Pt100,

external Pt100 and return flow sensor)

2-point 5-point 5-point

Monitoring (low level, overtemperature

2

)

Adjustable alarm thresholds

VPC (Variable Pressure Control)

3

Ventilation program

Automated compressor

Setpoint limitation

1

TAC function available as a 30 day evaluation version.

2

For temperature control units with integrated overtemperature protection.

3

For units with variable-speed pump or external bypass.

Overview of the

E-grade variants

Overview of

E-grade functions

Loading...

Loading...