34

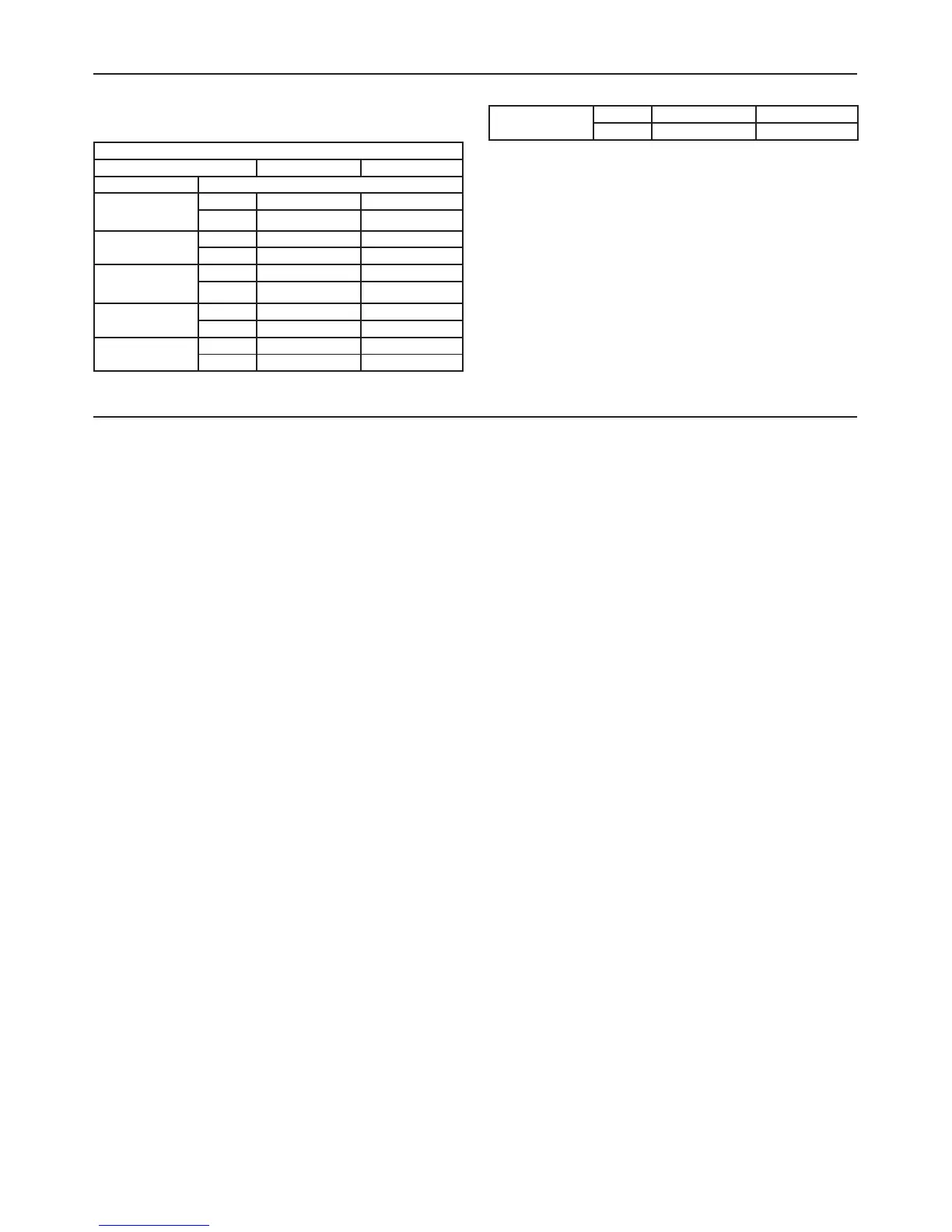

Ashrae Color Code

NOTE: All other manufacturers have no standard sensor codes.

Case Control Systems SENSOR COLOR

Manufacturer ® > EIL CPC

Location

Coil Inlet

Color Blue Blue

Part# 225-01-1755 225-01-3255

Coil Outlet

Color Red Red

Part# 225-01-1757 225-01-3123

Discharge Air

Color Green Green

Part# 225-01-1756 225-01-3260

Return Air

Color Purple Green

Part# 225-01-1758 225-01-3260

Defrost Term.

Color White Orange

Part# 225-01-0650 225-01-3254

Liquid Line

Color White Blue

Part# 225-01-0650 225-01-3255

Electrical (Cont'd)

User Information

Stocking

Improper temperature and lighting will cause serious

product loss. Discoloration, dehydration and spoilage

can be controlled with proper use of the equipment and

handling of product. Product temperature should always

be maintained at a constant and proper temperature.

This means that from the time the product is received,

through storage, preparation and display, the temperature

of the product must be controlled to maximize life of the

product. Hussmann cases were not designed to “heat up”

or “cool down” product-but rather to maintain an item’s

proper temperature for maximum shelf life. To achieve the

protection required always:

1. Minimize processing time to avoid damaging

temperature rise to the product. Product should be

at proper temperature.

2. Keep the air in and around the case area free

of foreign gasses and fumes or food will rapidly

deteriorate.

3. Maintain the display merchandisers temperature

controls as outlined in the refrigerator section of this

manual.

4. Do not place any product into these refrigerators

until all controls have been adjusted and they

are operating at the proper temperature. Allow

merchandiser to operate a minimum of 6 hours

before stocking with any product.

5. When stocking, never allow the product to extend

beyond the recommended load limit. Air discharge

and return air fl ue must be unobstructed at all

times to provide proper refrigeration.

6. There are vents located at the base of the front of the

glass, just above the front rail. These vents supply a

continuous, gentle ! ow of air across the front glass

which inhibits condensation. Do not place any

signs or other restrictive objects on the front of

the refrigerator that will block these vents.

7. Keep the service doors closed (when applicable).

Refrigeration performance will be seriously affected

if left open for a prolonged period of time.

8. Avoid the use of supplemental ! ood or spot lighting.

Display light intensity has been designed for

maximum visibility and product life at the factory.

The use of higher output LED lamps (H.O. and

V.H.O.), will shorten the shelf life of the product.

9. In the Deli, Meat and Fish cases, completely cover

the product each night with a clean damp cloth or

butcher paper (never use plastic, as it does not

allow for proper circulation). Make sure the cloth or

paper is in direct contact with the product.

10. Turn and rotate the meat fairly often. The blood

which gives the pink color works its way downward

with time.

11. Cold coils remove heat and moisture from the

case and deposit this as frost onto the coil. Thus,

a defrost is required. Our humidity system induces

moisture into the case and helps slow down the

dehydration process. The only other moisture within

the case is that in the product itself. A single level of

meat will dry out faster than a fully loaded case of

3-4 levels of meat.

Important Steps

1. Do not set temperature too cold, as this causes

product dehydration. Product Temperature:

33°-35°F!

Set thermostat to cut in at 28°F discharge air. Meat

holding box: 32°F. Meat prep room: 55°F. Meat

bloom box: 36°F. Process the meat to enter case at

40°F or below. Product deterioration is very rapid

above 40°F.

Loading...

Loading...