5

Leveling

IMPORTANT! IT IS IMPERATIVE THAT CASES BE

LEVELED FROM FRONT TO BACK AND SIDE TO SIDE

PRIOR TO JOINING. A LEVEL CASE IS NECESSARY

TO INSURE PROPER OPERATION, WATER DRAINAGE,

GLASS ALIGNMENT, AND OPERATION OF THE HINGES

SUPPORTING THE GLASS. LEVELING THE CASE

CORRECTLY WILL SOLVE MOST HINGE OPERATION

PROBLEMS.

NOTE: A. To avoid removing concrete fl ooring, begin lineup

leveling from the highest point of the store fl oor.

B. When wedges are involved in a lineup, set them fi rst.

All cases were leveled and joined prior to shipment to

insure the closest possible ! t when cases are joined in

the ! eld. When joining, use a carpenters level and shim

legs accordingly. Case must be raised correctly, under legs

where support is best, to prevent damage to case.

1. Check level of " oor where cases are to be set.

Determine the highest point of the " oor; cases will

be set off this point.

2. Set ! rst case, and adjust legs over the highest part

of the " oor so that case is level. Prevent

damage - case must be raised under leg or by use

of 2x6 or 2x4 leg brace. Remove side and back leg

braces after case is set.

3. Set second case as close as possible to the

! rst case and level case to the fi rst using the

instructions in step one. The fronts of the cases

should be in alignment. Caution: do not use

connecting bolts to pull sections together.

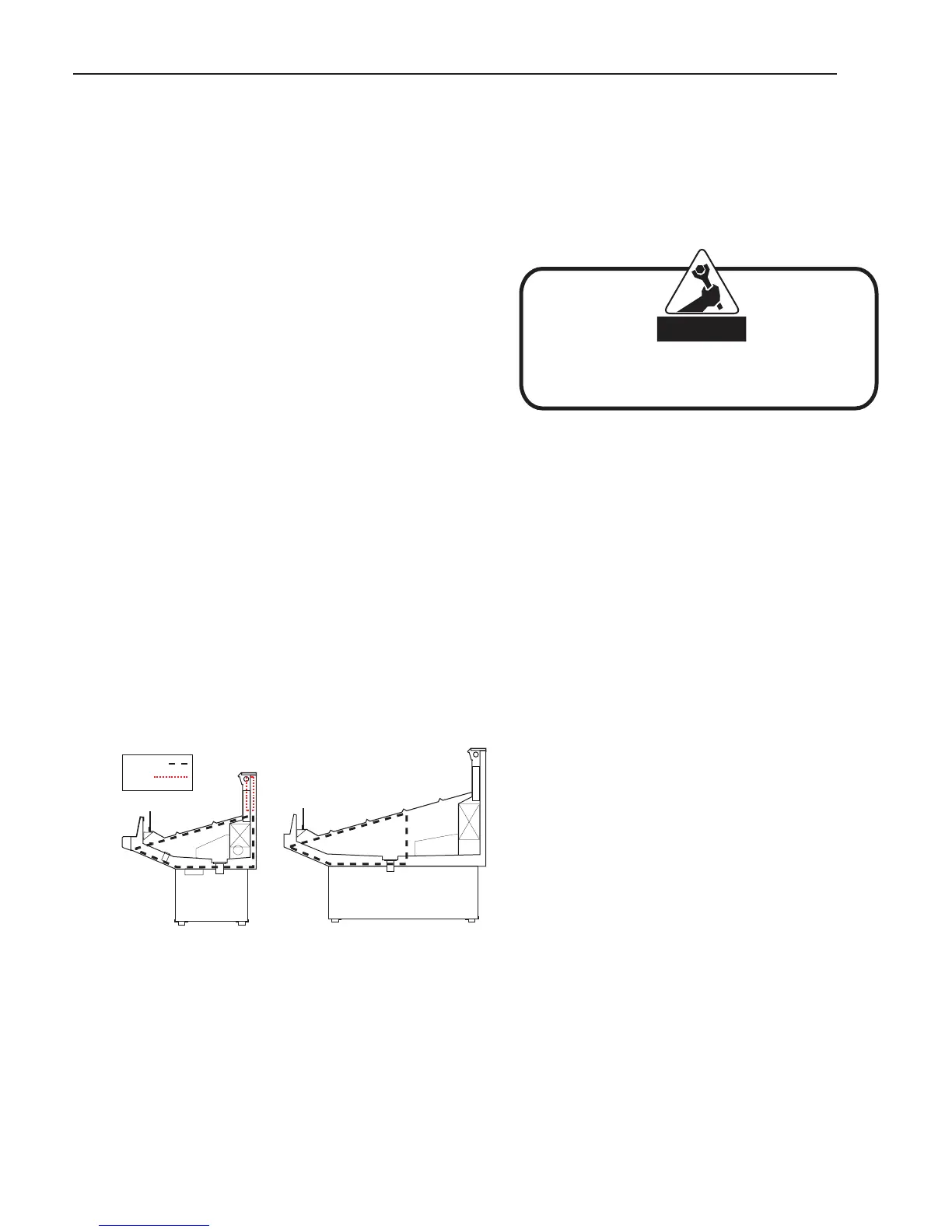

4. Apply a thick bead of 2-part epoxy to adjoining

end panels as illustrated in the following diagram,

especially around bulkhead cutouts and screw

holes. Apply liberal bead of 2-part epoxy between

cases along bulkhead and up the rear discharge

(grey silicone). Do not use Permagum because this

does not allow cases to draw up tight, and therefore

leaves gaps at the joint.

8. Connect applicable electrical, refrigeration, water,

and drain lines. See respective chapters for more

detailed instructions.

9. After cases have been leveled and refrigeration,

electrical, and waste piping work completed, install

the splashguards. (see instructions in the “Finishing

Touches” section of this booklet).

Note: Seal the unit to the fl oor with an NSF Listed caulk or

equivalent

Corner Wedges

Corner wedges are attached via front and rear camlocks.

Use a 7mm allen wrench to turn the locks. Do not

overtighten# Join the top by using a joint bracket (included

in joint kit) with 3/8” bolts.

Joint Trim

After cases have been leveled and joined, and refrigeration,

electrical, and wasted piping work completed, install the

splashguards. Fasten along the top edge, or center, with

$10 X 3/3” sheet metal screws.

Installation (Cont'd)

Loading...

Loading...