3.4

IDLER WHEEL ADJUSTMENT

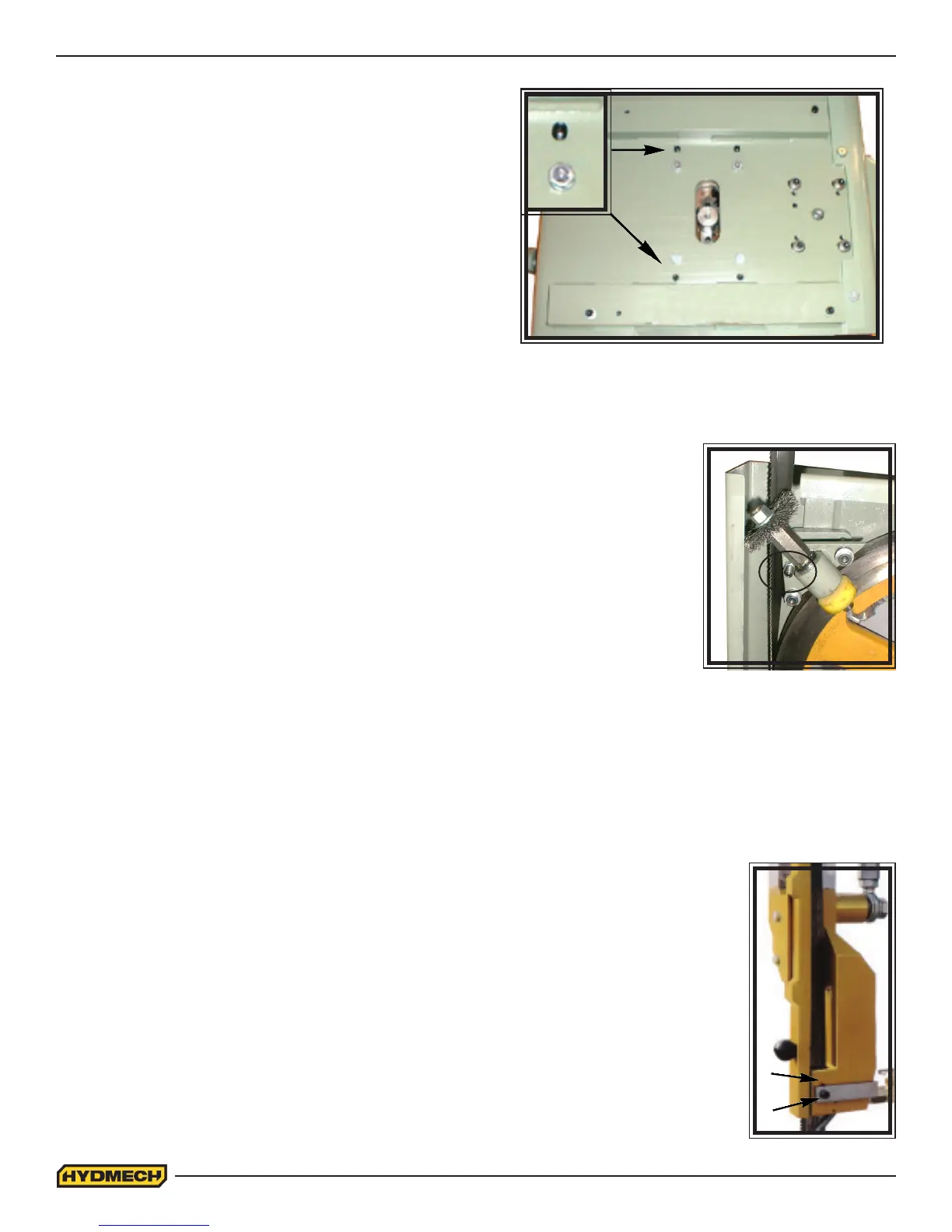

Adjustments should be made with the blade tension released

slightly. Remove the cover on the left side of the head. There are

four hex bolts (A) and four set screws (B & C). Bolts A are loos-

ened and then set screws B & C are adjusted by turning one out,

the other in 1/4 turn, and tightening the rst again. Adjust by 1/4

turn at a time and check the blade movement with each adjust-

ment by running the blade at minimum speed. Loosening B and

tightening C will push the blade o the wheel. Loosening C and

tightening B will pull the blade onto the wheel.

BLADE BRUSH ADJUSTMENT

The blade brush is properly set when the machine leaves the factory but it will wear during

operation and needs to be adjusted periodically. The blade brush assembly is shown right.

In order to adjust it, the nut on the adjusting screw needs to be loosened and the screw

turned counter clockwise to move the brush closer to the blade until the wires on the brush

touch the bottom of the blade gullets. If a new brush is being installed, then the adjusting

screw must be turned clockwise in order to move the new brush away from the blade so

that the wires are touching the bottom of the gullets.

If the brush gets worn to approximately 70% of its original 3” diameter it should be re-

placed. A brush may be purchased from your HYD-MECH dealer.

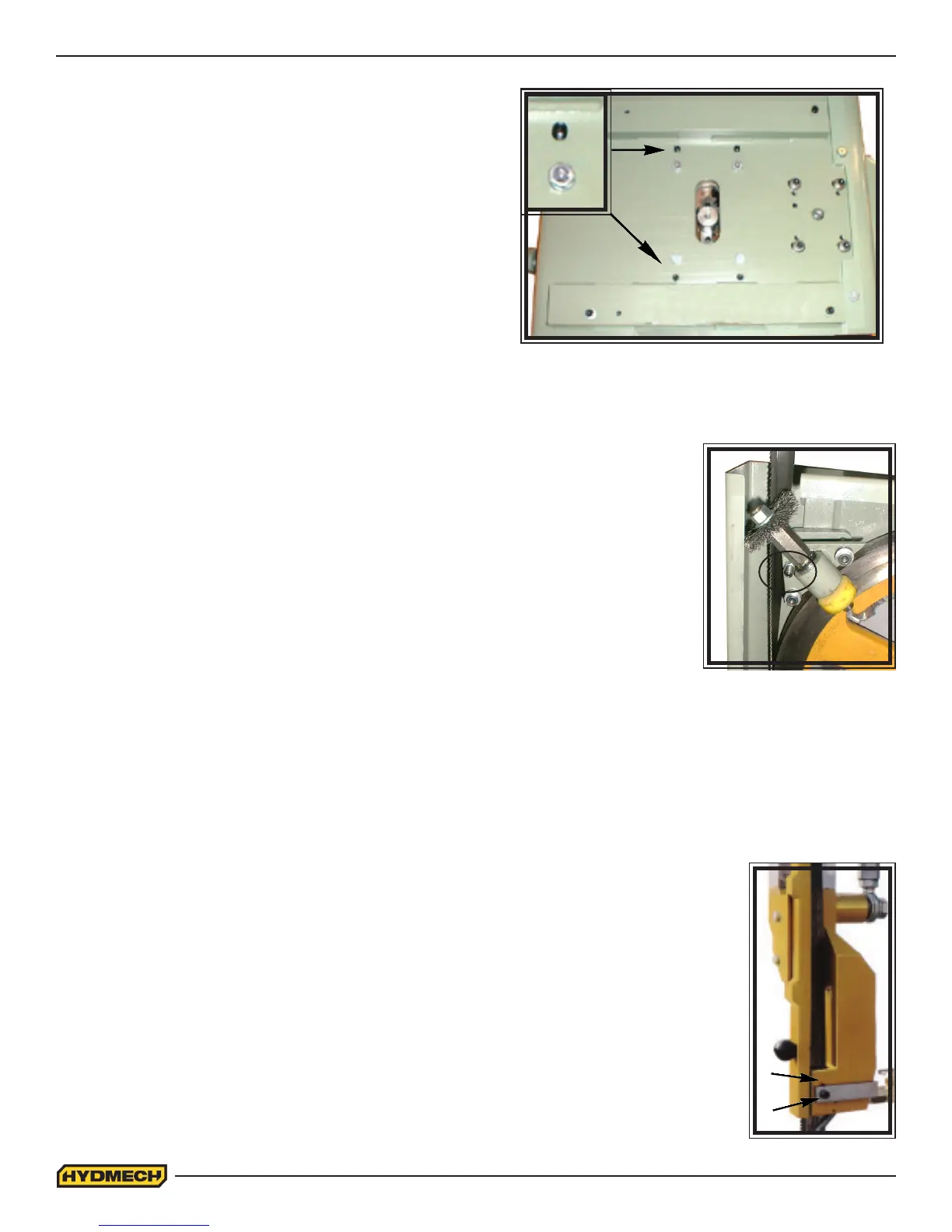

BLADE GUIDES

Both guide arms are provided with blade guide assemblies consisting of carbide pads that are

integral to the correct guidance of the saw blade. These guide assemblies will require an adjust-

ment (periodically, refer to TROUBLESHOOTING in this section for indications that adjustment

is needed). To adjust the pads properly, follow this simple procedure. With the lever in the locked

position, loosen the small set screw (A) in the edge of the lever. Turn the adjusting set screw (B)

clockwise until tight and then loosen it 1/8th of a turn. With the lever still in the locked position,

tighten the small set screw in the side of the lever. This should put just enough pressure on the

blade to permit you to push the blade out approximately 1/8”.

In the event that the pads must be replaced, refer to the exploded parts

drawing in Section 6.

Blade brush & adjusting

screw (circled).

B & C

A

B

A

A

C

Idler wheel tracking bolts (A) and set screws

(B & C) with the cover removed.

Blade guide adjust-

ing screws.

A

B

Loading...

Loading...